Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Chemical Name

- INCI Name

- CASE Ingredients Functions

- Composite Materials Functions

- Cosmetic Ingredients Functions

- Fluids & Lubricants Functions

- Plastics & Elastomers Functions

- CAS No.

- 67762-90-7

Features & Benefits

- Benefit Claims

- Labeling Claims

- CASE Ingredients Features

- Fluids & Lubricants Features

- Materials Features

- Product Features

- The silicone oil treatment guarantees the marked hydrophobia of the product

- Highly efficient effect in the thickening and thixotropy of complex polar liquids, such as those based on epoxy, polyurethane, or vinylester resins

- With silicone oil treatment, AEROSIL® R 202 offers a tailor-made chemical surface treatment.

- The high hydrophobicity of PDMS-treated, small particle AEROSIL® grades makes them particularly effective for achieving a high tribo-charge.

- At the same time, PDMS-treated, small particle AEROSIL® grades maintain good flowability.

Applications & Uses

- Markets

- Applications

- Compatible Polymers & Resins

- Fluids & Lubricants Type

- Fluids & Lubricants End Use

- Plastics & Elastomers End Uses

- Plastics & Elastomers Processing Methods

- AEROSIL® Fumed Silica in Lubricating Greases

AEROSIL® fumed silica helps to build a stable matrix to increase viscosity and suppress oil separation in lubricating greases. It can be used in the following systems:

- In non-soap greases, used in high-temperature applications up to 230° C as well as for extreme-pressure and multipurpose greases.

- In soap greases, thickened by fatty acid soaps of lithium, calcium, sodium or aluminum, AEROSIL® fumed silica can be used to further improve the performance of the lubricating grease.

- Hydrophilic fumed silica provides optimized thickening effects in non-polar oils.

- Hydrophobic fumed silica provides viscosity control and increased water repellency in semi-polar to polar oils.

- The surface area of the silica and the volume fraction of the silica in the fi nal mass play a role in the long term storage and heat stability.

- Cable Gel Applications

Use of AEROSIL® fumed silica for cable gels gives excellent performance when it comes to shear-thinning, providing quick recovery and the gel does not require heat to be applied. AEROSIL® fumed silica improves properties of oil-based filling compounds for wire and cables to protect fibers (e. g. optical fibers) as it:

- Supports to isolate sensitive optical fi bers from external forces

- Protects the fi bers from moisture

- Provides thickening to help the gel to stay where it is placed

- Helps to form a seal to keep out contaminants like dust, dirt and water

- Is non-conductive / does not negatively infl uence di-electrical properties

f - Applications

- Thickening and thixotropy control of adhesives and sealants for fiberoptic cables

- Thickening and thixotropy control of epoxy and vinylester resins

- Booster silica for defoamer formulations

- Anti-sedimentation aid for fillers, such as chalk or quartz powder

- Additive for formulation of anti-corrosion systems

- Improves flowability of powders

- Enables achieving of a high tribo-charge

- Lubricating Grease Applications

The use of AEROSIL® fumed silica is recommended for lubricating greases used in industrial applications, automotive, electrical as well as food grade.

- Electrical - Offers rheology control as well as water resistance.

- Industrial - Offers rheology control as well as excellent oxidation resistance against water and chemicals.

- Automotive - Offers rheology control as well as excellent oxidation resistance against water and chemicals.

- Food - Hydrophilic AEROSIL® are generally recognized as safe (GRAS; direct food contact). Offers rheology control as well as water resistance

Properties

- Appearance

- Fluffy white powder

- Physico-Chemical Properties

- Note

1 - According to DIN 9277

² - According to DIN EN ISO 787/11, JIS K 5101/20 (not sieved)

3 - According to DIN EN ISO 787/2, ASTM D 280, JIS K 5101/23

4 - According to DIN EN ISO 3262-20, ASTM D 1208, JIS K 5101/24

5 - According to DIN EN ISO 787/9, ASTM D 1208, JIS K 5101/26

6 - According to DIN EN ISO 787/18, JIS K 5101/22

7 - Based on dried substance (2 hours at 105 °C)

8 - Based on ignited substance (2 hours at 1000 °C)

9 - Special moisture-protective packaging

10 - in water: methanol = 1:1

11 - HCI-content is a part of ignition loss

12 - Packaging of densed material: 20 kg- Note

* ex plant

| Value | Units | Test Method / Conditions | |

| Unit Weight (Netto) | 10 | kg | - |

| HCI Content⁸,¹¹ | max. 0.025 | wt % | - |

| TiO₂ Content⁸ | max. 0.030 | wt % | - |

| Fe₂O₃ Content⁸ | max. 0.010 | wt % | - |

| Al₂O₃ Content⁸ | max. 0.050 | wt % | - |

| SiO₂ Content⁸ | min. 99.8 | wt % | - |

| Carbon Content | 3.5 - 5.0 | wt % | - |

| pH Value⁵ (4%, Aqueous dispersion) | 4.0 - 6.0 10 | wt % | - |

| Loss on Ignition⁴,⁷ (2h at 1000°C) | 4.0 - 6.0 | wt % | - |

| Loss on Drying³ (2h at 105°C, when leaving the plant) | max. 0.5 | wt % | - |

| Tamped Density² | 60 | g/l | - |

| BET Surface Area (BET¹) | 80 - 120 | m²/g | - |

| Behavior Towards Water | Hydrophilic | - | - |

Regulatory & Compliance

- Certifications & Compliance

- Chemical Inventories

Technical Details & Test Data

- Test Methods

- AEROSIL® fumed silica is a highly dispersed, amorphous, very pure silica manufactured by high-temperature hydrolysis of silicon tetrachloride in an oxyhydrogen gas flame. The primary particles formed in the AEROSIL® process are virtually spherical and free of pores.

- During the formation of the primary particles, aggregates are formed which further accumulate into agglomerates. Under shear, these agglomerates can be returned back into smaller aggregates.

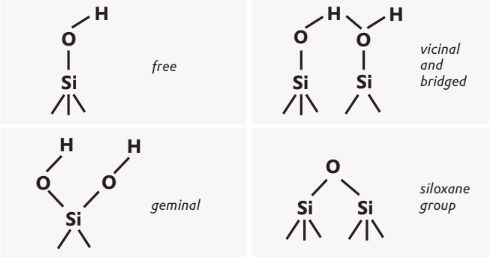

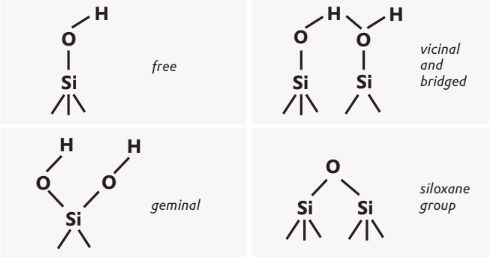

- Siloxane and silanol groups are found on the surface of the AEROSIL® particles. This latter type of functional group in particular is responsible for the hydrophilic behavior of untreated AEROSIL®. Figure shows the surface groups of hydrophilic AEROSIL® grades.

Surface groups of hydrophilic AEROSIL® grades.

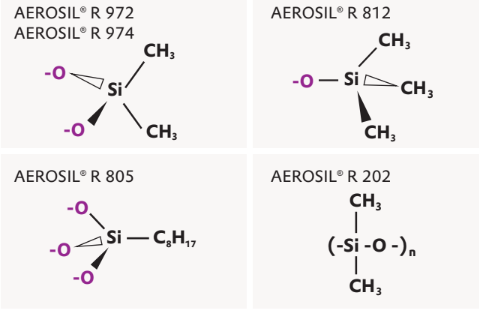

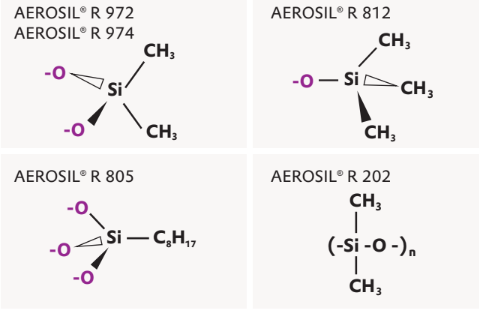

Figure below provides a summary of these and highlights the difference between them and hydrophilic AEROSIL® grades according to the schematically represented surface groups. All hydrophobic AEROSIL® grades bear the suffix "R" to indicate their water- repellent character.

Surface groups of hydrophobic AEROSIL® grades.

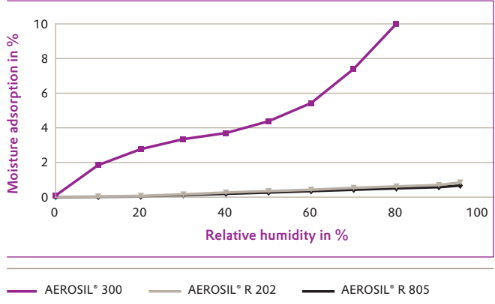

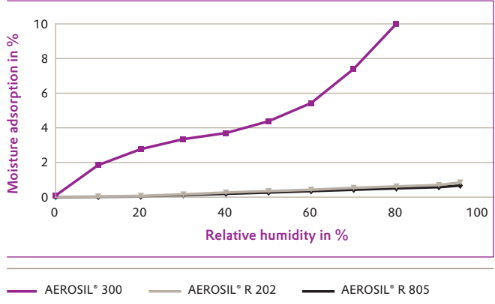

The hydrophobic nature of aftertreated AEROSIL® grades compared with AEROSIL® 300 can be illustrated by means of moisture adsorption in increasingly humid conditions. Figure below shows the corresponding isotherms.

Adsorption isotherms of various AEROSIL® grades at room temperature (small samples).

- AEROSIL® Fumed Silica

- AEROSIL® fumed silica is a highly dispersed, amorphous, very pure silica manufactured by high-temperature hydrolysis of silicon tetrachloride in an oxyhydrogen gas flame. The primary particles formed in the AEROSIL® process are virtually spherical and free of pores.

- During the formation of the primary particles, aggregates are formed which further accumulate into agglomerates. Under shear, these agglomerates can be returned back into smaller aggregates.

- Siloxane and silanol groups are found on the surface of the AEROSIL® particles. This latter type of functional group in particular is responsible for the hydrophilic behaviour of untreated AEROSIL®. Figure shows the surface groups of hydrophilic AEROSIL® grades.

Surface groups of hydrophilic AEROSIL® grades.

Figure below provides a summary of these and highlights the difference between them and hydrophilic AEROSIL® grades according to the schematically represented surface groups. All hydrophobic AEROSIL® grades bear the suffix "R" to indicate their water- repellent character.

Surface groups of hydrophobic AEROSIL® grades.

The hydrophobic nature of aftertreated AEROSIL® grades compared with AEROSIL® 300 can be illustrated by means of moisture adsorption in increasingly humid conditions. Figure below shows the corresponding isotherms.

Adsorption isotherms of various AEROSIL® grades at room temperature (small samples).

Packaging & Availability

- Packaging Type

- Regional Availability

- Packaging Information

AEROSIL® R 202 is supplied in multiple layer 10 kg bags.

Storage & Handling

- Shelf Life

- 2 years

- Storage Conditions

Recommend to store the product in closed containers under dry conditions and to protect the material from volatile substances. AEROSIL® R 202 should be used within 2 years after production.