Knowde Enhanced TDS

Identification & Functionality

- Flavor

- Flavor Ingredient Class

- Ingredient Name

- Food Ingredients Functions

- Ingredients

- Hops

- Technologies

- Product Families

Features & Benefits

- Product Highlights

- Stabilized Pellets are a hop product added to the wort kettle during the boiling process. They offer improved utilization of alpha acids due to the presence of excess Mg2+ ions added as MgO during processing.

- Stabilized Pellets can replace conventional hop products for bitterness and aroma without impacting beer quality.

- Stabilized Pellets exhibit fewer losses in bittering potential compared to standard pellets after prolonged storage.

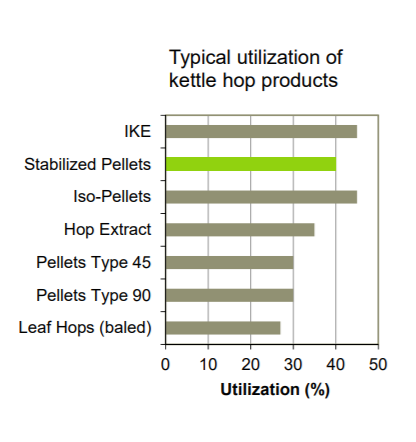

Typical utilization of kettle hop products

- Product Information

- Appearance

Stabilized Pellets are dark green pellets, approximately 6 mm x 10 – 15 mm in size (diameter x length).

- Standardization

The alpha acid content of Type 45 Stabilized Pellets can be standardized to specific concentrations during pellet production.

• Utilization

Given as an early kettle addition (up to 15 min after the boil begins), hop utilization normally falls within a range of 38 – 40 %. This higher utilization, compared to standard pellets, is due to the Mg++ ions catalyzing the rapid conversion of alpha acids to iso-alpha acids. When Stabilized Pellets are added late in the boil, utilization can decline to 30

% or less, depending on individual process conditions. Both additions can vary depending on the desired intensity and the beer style.

• Flavor

Stabilized Pellets produce flavors in beer indistinguishable from those of regular pellets. Stabilized Pellets provide bitterness and aroma to the beer. The flavor depends on the variety, quantity and time of addition. For further information, please refer to the hop variety data sheets.

• Quality

All Hopsteiner® products are processed in facilities which fulfill internationally recognized quality standards.

Applications & Uses

- Markets

- Applications

- Food & Nutrition Applications

- Product Use

Stabilized Pellets are used in similar ways to standard pellets, contributing bitterness and hop aroma to beer.

• Dosage

The quantity of Stabilized Pellets in an addition can be calculated using the alpha acid content of the pellets and an estimated or known utilization.

Late kettle additions of Stabilized Pellets (typically 5 – 20 min prior to the end of the boil) reduce alpha acid utilization but increase hop aroma and flavor.

• Addition

Stabilized Pellets can be added directly to the wort kettle or hop dosing vessel. Alternatively, owing to their free-flowing nature, additions of Stabilized Pellets can be automated. However, measures should be taken to avoid prolonged exposure to air in any bulk handling system.

Properties

- Physical Form

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Alpha acids | 1 – 25 | % | - |

| Beta acids | 1 – 14 | % | - |

| Hop oil | 0.2 – 7.0 | ml/100g | - |

| Moisture content | 7 – 9 | % | - |

Technical Details & Test Data

- Analytical Methods

- Concentration of Bitter Substances Alpha and beta acids can be measured by using the following methods:

- HPLC according to Analytica-EBC 7.7 orASBC Hops-15 with the current ICE standard

• Concentration of Hop Oil

The hop oil concentration can be measured using the following methods:

-

- Analytica-EBC 7.10

- ASBC Hops-13

- Concentration of Bitter Substances Alpha and beta acids can be measured by using the following methods:

- Technical Support

We are pleased to offer assistance and advice on the full range of Hopsteiner® products:

- copies of all relevant analytical procedures

- Safety Data Sheets (SDS)

- assistance with pilot or full-scale brewing trials

- special analytical services

Disclaimer: The information provided in this document is believed to be correct and valid. However, Hopsteiner® does not guarantee that the information provided here is complete or accurate and thus assumes no liability for any consequences resulting from its application.

Safety & Health

- Safety

When handling this product, it is advisable to wear a dust mask. Hop pellets are combustible.For full safety information, please see the relevant Hopsteiner® safety data sheet.

Packaging & Availability

- Packaging

Stabilized Pellets are packaged in metallized five-layer foil bags which are then packed in boxes. These are available as ‘soft’ packs flushed with inert gas (N2 and/or CO2) at atmospheric pressure. Pack sizes range from 5 kg (22 lb) to 18 kg (44 lb).

Storage & Handling

- Storage

Stabilized Pellets should be stored at low temperatures (< 5 °C or < 41 °F). Pellets in opened foil packs should be used quickly to avoid deterioration of the bitter acids and essential oils.

• Best Before Date

Stabilized Pellets are stable for six years from the date they were produced / packaged if stored under the recommended conditions.