Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Chemical Name

- CASE Ingredients Functions

- CAS No.

- 7779-90-0

- EC No.

- 231-944-3

- Technologies

- Product Families

- Chemical Description

Zn3(PO4)2.2H2O (dihydrate)

- Mechanism

- Precipitation and anodic passivation

Features & Benefits

- CASE Ingredients Features

- Features

HALOX® corrosion inhibitive pigments have provided a high standard of protection without the use of lead or hexavalent chromium compounds. ICL Phosphate Specialty proudly offers a variety of Inorganic Corrosion Inhibitors based on the proven performance of zinc. Our Z-PLEX® products are designed to allow you to choose the right inhibitor for your performance and manufacturing needs.

- Advantages

- HALOX® Z-PLEX 250 is a Type I dihydrate crystal based on ASTM D6280. It has a loss on ignition (LOI) between 8.5-9.0%

Applications & Uses

- Applications

- Compatible Polymers & Resins

- Compatible Substrates & Surfaces

- Coating Type

- Recommended Loading Levels

Recommended loading levels range from 5-10% based on total formula weight.

- Applications

- Short Oil Alkyds

- Medium Oil Alkyds

- Long Oil Alkyds

- Solvent 2K Epoxies

- Epoxy Esters

- Latex Emulsions

- Polyesters

- PVDC

- Water Reducible Epoxies

- WR Alkyds

- High Solids Epoxies

- Water Based Epoxy Esters

- Thin Film Applications

- Acrylic Lacquer Emulsions

- Acid Catalyzed Systems

Properties

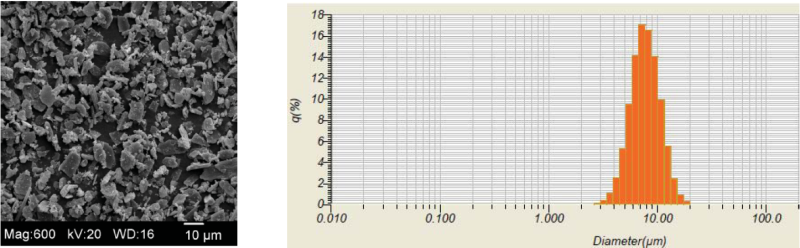

- Appearance

- White Powder

- Typical Properties

| Value | Units | Test Method / Conditions | |

| D100 Horiba | max. 20 | microns | - |

| D50 Horiba | 5 - 7 | microns | - |

| Density | 3.28 | g/cm³ | - |

| Hegman Grind | 5.5 - 6.0 | ||

| LOI (at 600°C) | 9 | % | - |

| Oil Absorption | 24 - 26 | lbs/100 lbs | - |

| pH (10% Solution by Weight) | 7.5 | - | - |

Regulatory & Compliance

- Certifications & Compliance

Technical Details & Test Data

- Technical Data

Storage & Handling

- Shelf Life

- 36 Months