- Polymer Name:Polyamide 12 (PA 12)

- Processing Methods:Injection Molding, Pipe Extrusion, Tubing Extrusion, Profile Extrusion, Extrusion

- Additives Included:Plasticizer (Unspecified), Impact Modifier, Lubricant (Unspecified), Light Stabilizer, Heat Stabilizer

- Flexural Modulus:399.62 - 399.62 MPa

- Materials Features:Good Thermal Stability, Low Coefficient of Friction, Low Temperature Impact Resistance, Oil Resistant, Impact Modified, Electrically Insulating, Lubricated, Fuel Resistant, Light Stabilized, Easier Processing, Good Light Stability, Chemical Resistant, Semi Crystalline, Flexible, Unreinforced, Heat Stabilized, Good Weather Stability, Very Good Heat Resistance, Good Impact Strength, UV Resistant, Low Moisture Absorption, Impact Resistance, High Viscosity, Plasticized

- Color:Black

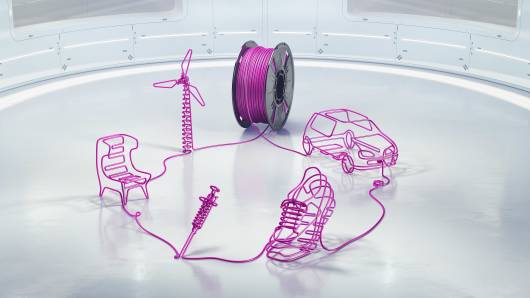

VESTAMID® X7293 BK 9.7507 is a plasticized polyamide 12 compound formulated with heat and light stabilizers for the extrusion of flexible tubing and hoses, particularly suited for automotive applications. This compound conforms to standards such as DIN 73378 (PA 12-HIPHL, Type 1), ISO/DIN 7628-1 (PA 12-HIPEHL, Type 1), and SAE J844. VESTAMID® X7293 BK 9.7507 offers easy processing and high impact strength at low temperatures. Its low moisture absorption ensures minimal variation in properties with changing humidity. Manufactured from this semicrystalline material, parts exhibit exceptional impact strength, a low coefficient of friction, and good chemical resistance. Supplied as cylindrical granules in moisture-proof bags, VESTAMID® X7293 BK 9.7507 is conveniently ready for use. Choose VESTAMID® X7293 BK 9.7507 for its reliability and superior performance in extrusion applications, ensuring excellent results for your automotive tubing and hose needs.