AdvanSix

AdvanSix Acetone NF Grade

Chemical Name: Acetone

Functions: Solvent, Intermediate

CAS Number: 67-64-1

Chemical Family: Ketones

Grade: Pharma Grade

Labeling Claims: Low Toxicity, Low Water Content, High Purity

Synonyms: 2-Propanone, beta-Ketopropane, Dimethylketone, Ketone Propane, Methyl Ketone, Propan-2-one, Propane-2-one, Propanone

AdvanSix High Purity Acetone NF Grade meets or exceeds certification requirements of the National Formulary. It is produced to the highest standards for key industries, including Building & Construction, Agriculture & Feed, Automotive & Transportation, Adhesives & Sealants, Paints & Coatings, Electrical & Electronics, Packaging, Personal Care, and Pharmaceuticals & Healthcare. Offering low impurities, low Benzene, and low water content, AdvanSix High Purity Acetone NF grade can be used as an intermediate in the production of:

Building and Construction

Construction and repair adhesives, exterior insulation and finishing systems, glazing and window elements, pipe and plumbing cement systems, and roofing sealants and caulks.

Agriculture & Feed

Agricultural pest control and industrial weed and vegetation control products.

Automotive & Transportation

Automotive aftermarket parts, exterior and body parts, interior parts and lighting, and coatings for aerospace, automotive OEM, marine, rail, mass transit, off-road and commercial vehicle applications.

Electrical & Electronics

Devices and assemblies for automotive and consumer electronics, packaging and assembly adhesives and sealants, printed circuit boards, and other semiconductor manufacturing applications.

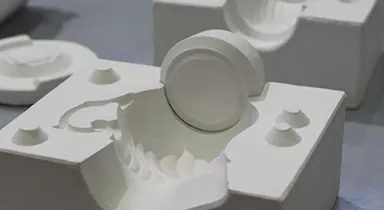

Healthcare & Pharma

Oral and dental drug delivery solutions, tubing and fluid handling equipment, excipients, coatings and processing aids and nail care applications.

Paints & Coatings

Architectural coatings, decorative paints, wood coatings and finishes, flooring and surface coatings, infrastructure coatings and markings, and packaging coatings for film and foil, overprint varnishes, primers and lacquers, and other aerosol coating applications.