Knowde Enhanced TDS

Identification & Functionality

- Plastics & Elastomers Functions

- Technologies

Features & Benefits

- Labeling Claims

Applications & Uses

- Markets

- Applications

- Plastics & Elastomers End Uses

- Plastics & Elastomers Processing Methods

- Use

- The use rate of MBD 50699 depends on expected final properties.

Properties

- Physical Form

- Typical Properties

- Thermal Properties

- Physico-Chemical Properties

- Use

The use rate of MBD 50699 depends on expected final properties.

PROPERTIES TEST STANDARD UNIT RESULT Dilution 30% Dilution 22% Dilution 15% PHYSICO-CHEMICAL Density ISO 1183-1 Method A g/cm3 1.04 0.98 0.95 Content intern method % 20 15 10 THERMAL Melting point ISO 11357-3 °C 160/170 160/170 160/170 Heat deflection temperature ISO 75-2/Af °C 76 71 65 MECHANICAL Tensile test Stress at yield point ISO 527-2/1A MPa 23 22 21 Stress at break MPa 16 14 14 Elongation at break % 10 10 15 Flexural test Flexural modulus ISO 178 MPa 2700 2300 2100 Impact test Charpy notched 23°C ISO 179-1/1eA kJ/m2 3.5 4.2 4.7 Charpy notched -20°C ISO 179/1eA kJ/m2 2.4 2.4 2.4

| Value | Units | Test Method / Conditions | |

| Bulk Density | 1 | g/cm3 | ISO 60 |

| Moisture Content | max. 0.15 | % | intern |

| Value | Units | Test Method / Conditions | |

| Vicat Softening Point | 155 | °C | ISO 306/A50 |

| Value | Units | Test Method / Conditions | |

| MVI (at 230°C-10Kg) | approx. 30 | cm3/10min | ISO 1133-1 |

Regulatory & Compliance

- Food Contact

- The MBD 50699 can be used for food contact applications in particular conditions. For any information about the regulatory conformity, please contact the Q.S.E. department of the company.

Technical Details & Test Data

- Compounds & Masterbatches

For High Performance Plastic

YOU WANT TO IMPROVE RIGIDITY AND HEAT DEFLECTION TEMPERATURE YOU WANT TO REDUCE WEIGHT ?

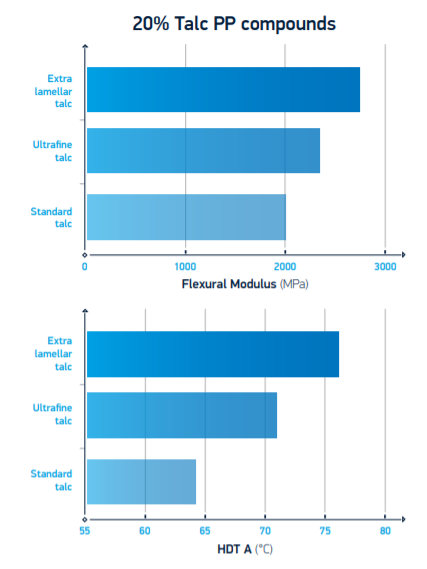

20% Talc PP compounds

Our innovative Extra lamellar Talc PP Compounds in comparison with standard and ultrafine talc.

- Comparission

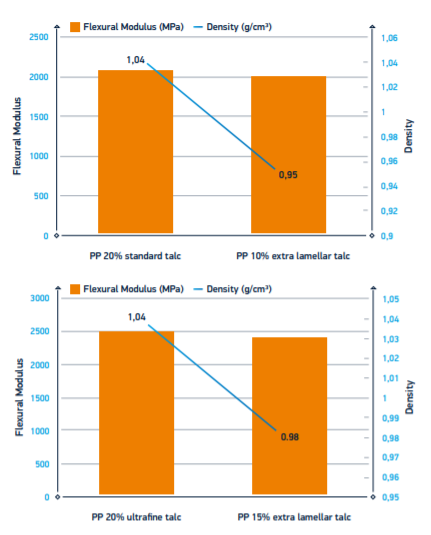

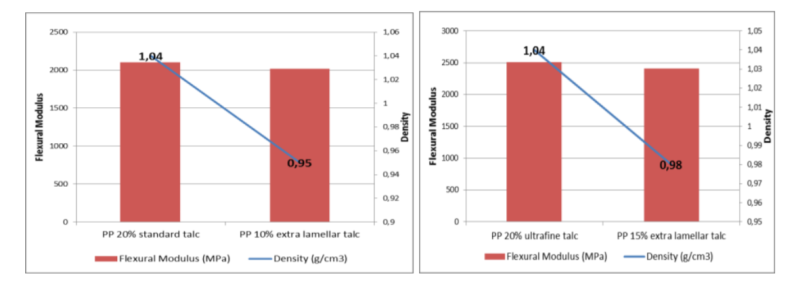

In comparison with standard talc and according to the used rate, the MBD 50699 allows to increase significantly the strength and the Heat Deflection Temperature (HDT).of the PP.

Moreover, the MBD 50699 added in PP resin brings much improved dimensional stability (low CLTE).

At the sight of the performance gap, this masterbatch can be added in lower rate and consequently induce an important weight reduction.

Packaging & Availability

- Packaging Type

- Packaging

- This masterbatch is packed in PE bag

Storage & Handling

- Storage

- This must be stored protected from light and from humidity.