Knowde Enhanced TDS

Identification & Functionality

- Backing Material Type

- Carrier

- Product Type

- Technologies

Features & Benefits

- Labeling Claims

- Ready-to-Use Product Features

- Key Attributes

- Clear construction for verification of wicking

- Cover attachment easily bonded to a pressure-sensitive mid-layer

- Wettable to liquids such as water, urine and blood

- Used as an aid for transport of fluids in capillary and microfluidic devices

- Fast and stable capillary fills

- Good esthetic quality

- Compatible with many assays

Applications & Uses

- Markets

- Application Area

- Compatible Substrates & Surfaces

- For Best Results

- The surfaces you wish to bond should be clean and free of oil, moisture and dust. If the surface temperature is below 40°F, it may be difficult to achieve a proper bond.

- Do not use a pressure-sensitive adhesive product where it will be exposed to temperatures lower or higher than those designated for each product. Heat can destroy the effectiveness of the bond and extreme cold can cause the adhesive to harden and not adhere properly.

- When the tape is applied, use firm hand or lamination pressure to achieve contact between the adhesive and the surface to which it is applied. Hand rollers or nip rollers may be needed for certain products or applications.

Consult your AR sales representative if you need additional information.

- Applications

The typical use for this product is for assemblies of in-vitro diagnostic and related membranebased immunoassay products where enhanced surface wettability to water, urine, blood and other hydrophilic liquids are required.

Properties

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Recommended Storage of Unconverted Product (50% ± 20% RH ) | 21 ± 11 | °C | — |

| Water Contact Angle | 4 - 10 | ° | Goniometer - 2 µL water drop; 30 sec. dwell |

| Contact Angle with Water (2 μL water drop; 30 sec. dwell) | 4 - 10 | ° | Goniometer |

Technical Details & Test Data

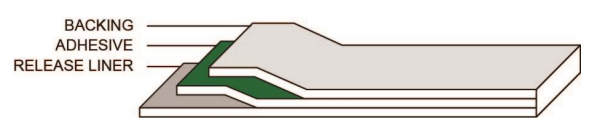

- Product Construction

Typical Values Description Film thickness 4.0 mil 100 μm Clear polyester film Adhesive thickness 0.4 mil 11 μm HY-10 hydrophilic coating Liner thickness 1.5 mil 38 μm Clear polyester release liner Total thickness 4.4 mil 111 μm (Excluding liner) - Note

- All stated values are nominal and should only be used as a guide for selection. They are not specifications. The information contained on this data sheet is based upon test results of limited quantities of this material and may be modified by Adhesives Research following additional production experience and evaluation. This data should not be used in preparing specifications. Products identified as developmental may be subject to modification by Adhesives Research, Inc.

- Recommended Sealing Parameters

120-145°C, 30-40 psi, 1-3 second dwell

Storage & Handling

- Shelf Life

- 1 Year

- Shelf life of Unconverted product

- Not to exceed one year from date of manufacture

- Handling Recommendations

- The hydrophilic heat seal adhesive is sensitive to surface impurities. It is recommended that the coated samples be handled using powder-free gloves and in an area that is away from dirt, silicones or other types of oils.

- Storage of Pressure-Sensitive Adhesive Tapes

- Pressure-sensitive adhesive tapes function as a mechanical product however, the adhesive itself is a chemical composition that can be sensitive to environmental conditions. A purchaser of pressure-sensitive adhesive products should be aware of the shelf life of each product and not purchase more than it can use before the expiration date. Shipping and storage conditions affect shelf life. The optimum storage temperature is 70 °F (21 °C). Cool, dry storage is recommended.

- Recommended Storage of Unconverted Product

- 21 ± 11 °C (50% ± 20% RH)