Knowde Enhanced TDS

Identification & Functionality

- Catalyst Support

- Chemical Family

- Chemical Name

- CASE Ingredients Functions

- Cosmetic Ingredients Functions

- Plastics & Elastomers Functions

- CAS No.

- 7631-86-9

- EC No.

- 231-545-4

- Product Families

Features & Benefits

- Benefit Claims

- CASE Ingredients Features

Applications & Uses

- Applications

- Plastics & Elastomers End Uses

- Use Level

- 1-5%

- Application Information

Cosmetics and Personal Care

SOLESPHERE™ silica gels are used as additives in cosmetic and personal care applications such as make-up, skin care products, deodorants and fragrances.

Resins and Polymer Compounds

When added to polymer formulations, SOLESPHERE™ silica gels offer anti blocking and improved dielectric insulation properties. SOLESPHERE™ also provides good UV and hardness properties as an additive for 3D resins.

Catalyst Supports

SOLESPHERE™ is used as a catalyst support carrier particularly with polyolefin manufacturing processes.

Paper Coating

By adding SOLESPHERE™ to paper coating formulations, surface hardness can be increased and matting effect improved.

Coatings

SOLESPHERE™ silica gels are used to improve the matting effect in coatings, as a thickener for paints, and for specialized paints for electronic materials.

- Formulating with SOLESPHERE™ Silica

SOLESPHERE™ provides excellent formulation flexibility as it can be added to any phase of the formulation. Through product and application testing, it has been shown SOLESPHERE™ silica provides the same effects in the formulation regardless of whether they are added to the water phase/aqueous phase, oil phase, or even if added at the very end.

- The effects of the silicas will show with just 1% added, however, adding more can increase benefits. 2-2.5% is the typical loading level.

- It is not recommended to add more than 3-4% in total silica content. This can result in the formulation appearing “chunky.”

- Multiple SOLESPHERE products can be added to a formulation to achieve different desired goals, but it is important to not go over the 3-4% total.

- Significant SPF boosting with H-53 and H-52 will show with just 1-2% added.

Properties

- Physical Form

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Bulk Density | 0.55 | g/mL | — |

| Mean Particle Size | 4 | μm | — |

| Oil Absorption | 30 | mL/100g | — |

| Pore Volume | 0.05 | mL/g | — |

| Specific Gravity | 2.18 | g/mL | — |

| Specific Surface Area | 40 | m²/g | — |

Technical Details & Test Data

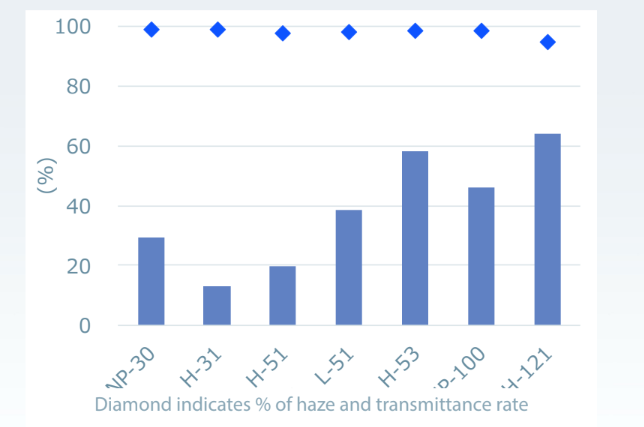

- Haze and Total Transmittance of SOLESPHERE Grades

The higher the particle size, higher the blur effect and the amount of oil absorption.

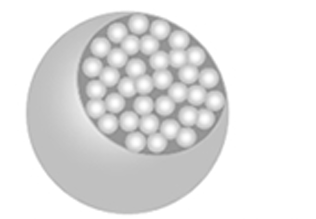

- Particle Structure

- L-series Primary particle is larger than H-series one

- Same oil absorption as H series and lower specific surface area

- Lower surface silanol group than H series

Safety & Health

- Safety and Handling

A Safety Data Sheet for this product may be obtained from your local AGC representative. Before handling, it is recommended to review the Safety Data Sheet for handling, safe, and health information.

Packaging & Availability

- Packaging

SOLESPHERE™ is packaged in a triple lined polyethylene bag contain in a cardboard carton. The box unit is 25 kgs for all NP grades. Pallet weight is 450 kgs.

Storage & Handling

- Shelf Life

- 2 Years

- Storage and Shelf Life

SOLESPHERE™ silica gels have a shelf life of 2 years from the date of manufacture when stored in the original, unopened package between 10 and 40 ºC.