Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Plastics & Elastomers Functions

- Technologies

- Product Families

- Structure

Features & Benefits

Applications & Uses

- Markets

- Applications

- Compatible Polymers & Resins

- Plastics & Elastomers End Uses

- Plastics & Elastomers Processing Methods

- Recommended Applications

Spray Polyurea Coatings

- Truck Bed Liners - OEM, After Market

- Water Proofing Membrane - Amusement park tanks, Bridges, Pipe, coating, High-speed rail, Concrete

- Secondary Containment - Oil and Gas

Epoxy Composites

- Filament wound epoxy pipe

- Syntactic foam

- Grinding wheel

- Electrical laminates

Polyurethane Cast Elastomer

- Wheels

- Belts

- Tools

- Rollers

PU Foam

- Building Insulation, Roofing

RIM

- Vehicle parts

Polyurea Applications

- Adjustable reaction times

- Outstanding mechanical performance

- Ease of processing

- Zero dust exposure

Epoxy Applications

- Good “wetting” characteristics

- High glass transition temperatures (Tgs)

- Exceptional chemical resistance

- Low moisture accumulation

- Value in Polyurea Applications

Ethacure 100 is the workhorse curative for polyurea and polyurethane applications particularly, spray applications.

It is a high quality, liquid product that delivers exceptional product benefits such as:

- Adjustable reaction times

- Outstanding mechanical performance

- Ease of processing

- Zero dust exposure

Integrating E100 in polyurea coating engineering equips formulators and end-users with increased versatility, adjustability, and dynamic performance advantages

- Value in Epoxy Applications

Ethacure 100 is a viable curative for use in epoxy applications, and as an MDA replacement in the production of filament wound pipe. Cured parts display high-grade benefits such as:

- Good “wetting” characteristics

- High glass transition temperatures (Tgs)

- Exceptional chemical resistance

- Low moisture accumulation

Properties

- Physical Form

- Appearance

- Clear, Yellow Liquid

- Miscible in

- Toluene, Ethanol, Toulene

- Typical Properties

- Typical Composition Properties

| Value | Units | Test Method / Conditions | |

| Boiling Point | 308 | °C | — |

| Water | 1 | — | — |

| Equivalent weight with epoxy resins | 44.6 | — | — |

| Equivalent weight with isocyanates | 89.1 | — | — |

| Density (20°C) | 8.5 | lb/gal | — |

| Ethanol Solubility | Miscible | — | — |

| Flash Point (TCC) | min. 135 | °C | — |

| Molecular Weight | 178.28 | g/mol | — |

| Pour Point | -9 | °C | — |

| Viscosity (20°C) | 280 | cSt | — |

| Viscosity (25°C) | 155 | cSt | — |

| Value | Units | Test Method / Conditions | |

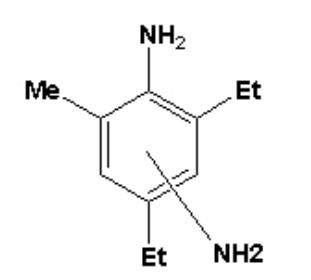

| 3,5-diethyltoluene-2,4-diamine | 75 - 81 | % | — |

| 3,5-diethyltoluene-2,6-diamine | 18 - 24 | % | — |

| Dialkylated m-phenylenediamines Content | 0.5 - 3 | % | — |

| Water | max. 0.08 | % | — |