Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Chemical Name

- Plastics & Elastomers Functions

- CAS No.

- 79-94-7

- EC No.

- 201-236-9

- Technologies

- Product Families

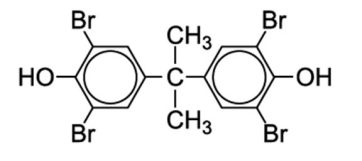

- Structure

Features & Benefits

- Materials Features

- Benefits and Features

SAYTEX CP-2000 flame retardant is a highly pure flame retardant containing very stable aromatic bromine. It can be used as a reactive or additive flame retardant.

As a reactive flame retardant, SAYTEX CP-2000 flame retardant finds particular application as a reactive monomer in epoxy and polycarbonate polymers. It is very cost-effective and once reacted, it is permanent and non-migrating.

SAYTEX CP-2000 flame retardant is a major component in epoxy oligomers used as additives for styrenic polymers and many engineering thermoplastics. Properties of note are improved polymer viscosity and UV resistance.

As an additive flame retardant, SAYTEX CP-2000 flame retardant is widely used in ABS. It melt blends into these systems, resulting in excellent processability, impact strength and moderate-range UV stability.

SAYTEX CP-2000 flame retardant is generally used with a synergist such as antimony oxide for maximum flame retardant performance

Applications & Uses

- Applications

- Compatible Polymers & Resins

Properties

- Appearance

- White

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Water Solubility (25°C) | max. 0.01 | wt. % | — |

| Toluene Solubility (25°C) | 6.4 | wt. % | — |

| Dielectric Constant (1 MHz) | 2.18 | — | — |

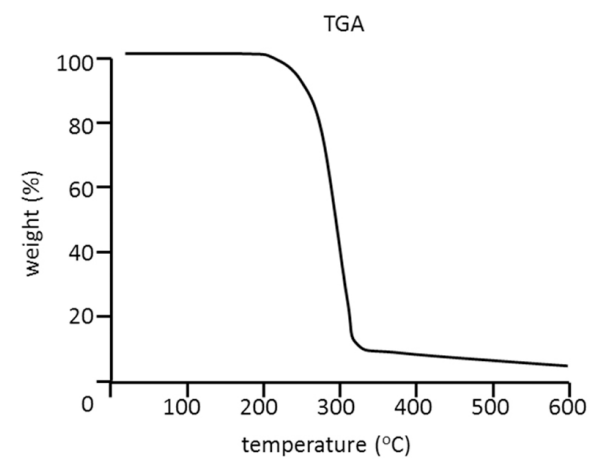

| TGA (10°C/min, under N2, 90% weight loss) | 459 | °C | — |

| Dissipation Factor (1 MHz) | 0.17 | — | — |

| TGA (10°C/min, under N2, 50% weight loss) | 310 | °C | — |

| Epoxy Resin (Dow DER343) | max. 0.1 | — | — |

| TGA (10°C/min, under N2, 5% weight loss) | 251 | °C | — |

| Melting Point | 181 | °C | — |

| TGA (10°C/min, under N2, 10% weight loss) | 267 | °C | — |

| TGA (10°C/min, under N2, 1% weight loss) | 222 | °C | — |

| Molecular Weight | 543.9 | g/mol | — |

| Styrene Solubility (25°C) | 8.5 | wt. % | — |

| Specific Gravity | 2.18 | — | — |

| Refractive Index | 1.73 | — | — |

| Methanol Solubility (25°C) | 47.2 | wt. % | — |

| Bulk Density (Packed) | 76.5 | lb/ft³ | — |

| Bulk Density (Aerated) | 53 | lb/ft³ | — |

| Bromine (Theoretical) | 58.8 | % | — |

| Acetone Solubility (25°C) | 69.6 | wt. % | — |

Regulatory & Compliance

- Chemical Inventories

Technical Details & Test Data

- TGA Profile

Packaging & Availability

- Country Availability

- Regional Availability