Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Chemical Name

- Pharma & Nutraceuticals Functions

- CAS No.

- 9004-65-3

- EC No.

- 618-389-6

- Technologies

Features & Benefits

- Benefits

- Smooth finish

- Ready - to-use

- Fast application

- Excellent moisture sealing

- Product Highlights

Challenges

- Protecting moisture sensitive substances from environmental moisture is one of the biggest challenges in the pharmaceutical and nutritional supplements industry.

- Coating the tablet core with a suitable film coating therefore plays an important role in achieving a sufficient moisture barrier. It improves the stability of the tablet and provides protection to prevent degradation of the active ingredients and increases shelf life. Tablet cores with highly hygroscopic active ingredients, such as extracts, or solid dosage forms marketed in countries with high humidity, must be protected from moisture effectively.

- The selection of raw materials for the formulation of AquaPolish® MS is adapted to the respective active ingredient and the customer‘s requirements. The transparent, white or colored tailor-made AquaPolish® MS formulations are homogeneous dry milled and easily soluble in water. Ready-to-use in less than one hour.

- Qualitative Composition

- Hydroxypropyl cellulose

- Hypromellose

- Triglycerides medium chain

- Talcum

Note: This is only an example of a possible clear formulation.

Applications & Uses

- Applications

- Manufacturing Technology

- Food & Nutrition Applications

Properties

Regulatory & Compliance

- Certifications & Compliance

- Grade

- Regulatory and Quality Aspects

- All AquaPolish® MS formulations are developed to meet the official regulatory requirements of the user’s country for pharmaceutical products and nutritional supplements.

- BIOGRUND is EXCiPACT™ certified and international standards for quality and environmental management (ISO 9001 & 14001) are implemented as well as a HACCP system. All products are produced in highest quality and a batch-to-batch consistency is guaranteed.

Technical Details & Test Data

- Film Properties

For the following data collection placebo tablets* were coated with three different white formulations (AquaPolish® MS, AquaPolish® based on HPMC, AquaPolish® based on PVA).

The solid concentrations and coating conditions were adjusted to the recommended values. The spray process stopped at a weight gain level of 4 % to compare all formulations under same conditions. All spray trials were performed on the laboratory drum coater BOSCH SolidLab1.

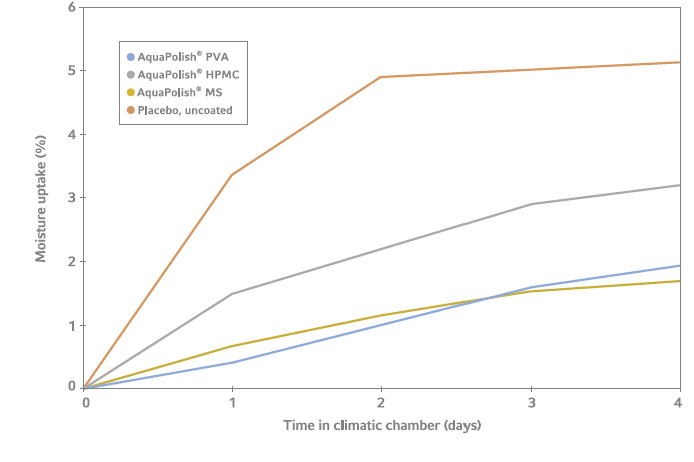

Moisture Barrier

Determination of moisture absorption – differential weighing: Before the coated tablets were placed in the climatic chamber, they were weighed. During the time in the climatic chamber (conditions: 40°C, 75% RH), the tablets were weighed every 24 hours to determine the moisture absorption. The results are shown in the graph Moisture Barrier (in %).

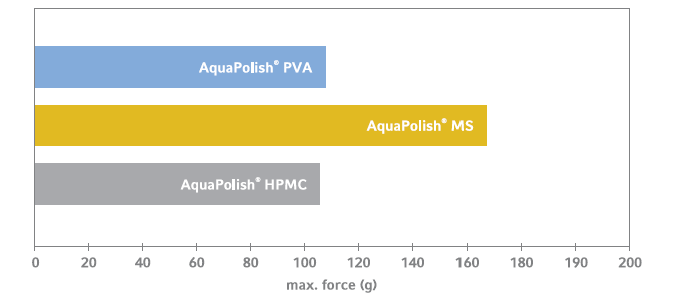

Film Strength

Size of each film sample was 3 x 3 cm (film thickness 22 μm avg. / 3 samples). Tested with a Texture Analyzer under compression load.

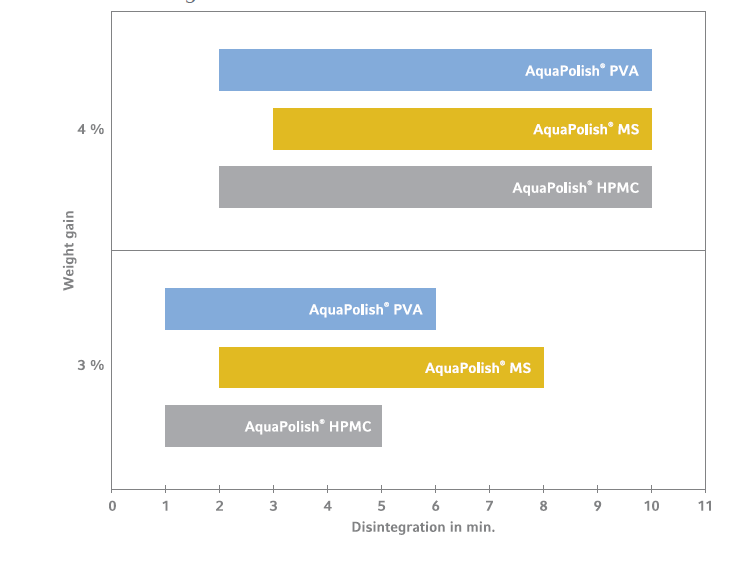

Disintergation

The disintegration test was carried out according to European Pharmacopeia (EP). Purified water was used as liquid medium (temperature 37 ± 2°C).

- Process Parameter

For achieving a reliable moisture sealing a weight gain level of 5 % is recommended. Local regulatory restrictions have to be considered. AquaPolish® MS is to be suspended in water up to a 15 % solids level.

Coating equipment Conventional Pan Side vented Pan Side vented Pan Pan diameter 16″ 24″ 48″ Tablet load 2 kg 30 kg 110 kg System Aqueous Solid content (%) 12 – 15 Pan Speed (rpm) 16 10 Baffles 8 4 Tablet bed temperature

38 – 42°C Fluid nozzle 1.0 mm 1.2 mm 1.2 mm Atomizing air pressure 1.0 – 1.2 bar 2.4 bar 2.4 bar Spray procedure Continuous Spray rate (g/min) 7 – 12 30 – 40 200 – 300 Inlet air temperature 50 – 52°C Exhaust air temperature

44 – 46°C Drying air volume 100 m³/h 500 m³/h 2400 m³/h Weight gain 5 %

Packaging & Availability

- Packaging

- Standard size: 25 kg carton (tamper evident box), with polyethylene inliner bag.

- Customized packaging available upon request.

Storage & Handling

- Shelf Life

- 24 Months

- Storage Conditions

Store product at 15-30°C under dry conditions (less than 65 % RH) 24 months from date of

manufacture (may vary based on pigment selection).