Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- CASE Ingredients Functions

- Plastics & Elastomers Functions

- Technologies

- Product Families

- Chemical Characterization

Brueggemann TP 1862 is a novel zinc-novolak-based, resorcinol and cobalt free crosslinker for steel-cord adhesion mixtures. Due to the compounding of the zinc-based catalyzing additive Brueggemann TP 1862 is dust-free and does not display any agglomeration effects. Brueggemann TP 1862 provides excellent vulcanization properties.

Features & Benefits

- Labeling Claims

- CASE Ingredients Features

- Materials Features

Applications & Uses

- Markets

- Applications

- Compatible Substrates & Surfaces

- Mixing Recommendation

- Due to its premixed nature Brueggemann TP 1862 can be easily added in the last step of the mixing process (internal mixer).

- After addition of the Brueggemann TP 1862 the mixing temperature should not exceed 120°C.

- Product Applications

Brueggemann TP 1862 allows the elimination of critically classified cobalt and cobalt salts as well as resorcinol from steel-cord adhesion mixtures without sacrificing vulcanization activity, mechanical properties, and adhesion characteristics.

- Dosage Recommendation

Brueggemann TP 1862 is added to the formulation as a 1:1 replacement for the total amount of zinc oxide, resorcinol, and cobalt salt (calculated as phr).

Properties

- Appearance

- Greenish granules

- Typical Properties

- Heavy Metals

| Value | Units | Test Method / Conditions | |

| Loss on Ignition (at 800°C) | min. 45 | % | — |

| Density | 1.6 | g/cm³ | — |

| Value | Units | Test Method / Conditions | |

| Heavy Metal Content (Pb, As, Cd) | max. 50 | ppm | — |

Regulatory & Compliance

- Certifications & Compliance

- Chemical Inventories

- International Listings

Brueggemann TP 1862 is compliant to REACH (EU), TSCA (USA), IECSC (China) and ECS/NSN (Taiwan).

Technical Details & Test Data

- Removing Cobalt and Resorcinol from Adhesion Mixtures

Steel-cord adhesion mixtures are commonly used in tires and other applications such as hoses or conveyor belts. In such mixtures, state-of-the-art technology uses systems containing cobalt salts as catalysts or co-accelerators and adhesion promotors, as well as resorcinol resins to achieve desired mechanical properties.

As both cobalt and cobalt salts, on one hand, and resorcinol, or resorcinol-based resins on the other hand, are deemed to be problematic from an environmental safety and health (ESH) point of view, it is worthwhile finding a solution to reduce – or even eliminate – such critical substances from modern rubber mixtures. The elimination of resorcinol is already realized by a novolakbased reinforcing resin.

A combination of this novolak-based resin together with a zinc-based catalyzing additive additionally allows the elimination of cobalt and cobalt salts from steelcord adhesion mixtures without sacrificing vulcanization activity, mechanical properties and adhesion characteristics.

- No cobalt

- No resorcinol

- High adhesion to steel

- High mechanical properties

- Low zinc and heavy metal content

Standard

systemCobalt- and

resorcinol-free

systemNR 100 100 N326 55 55 Stearinic acid 2 2 Silica 15 15 TMQ 1 1 Oil 4 4 Additive package 1 9.75 Additive package 2 8.5 HMMM 4 4 Sulfur 6 6 DCBS 0.6 0.6 TBBS 0.9 0.9 Additive package 1: Cobalt salt, resorcinol and standard ZnO

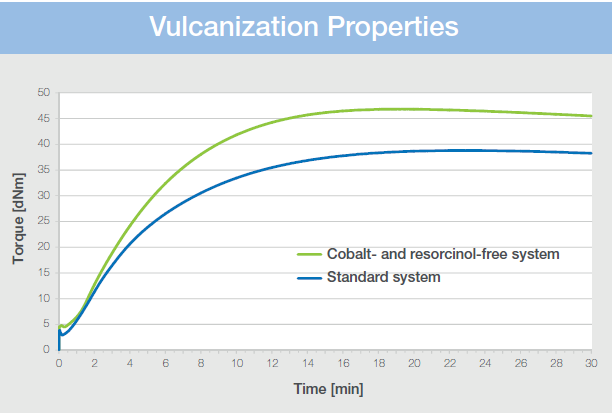

Additive package 2: Zinc- and novolak-based additive package without cobalt and resorcinolFig. 1: Rheometer curves measured at 155 °C.

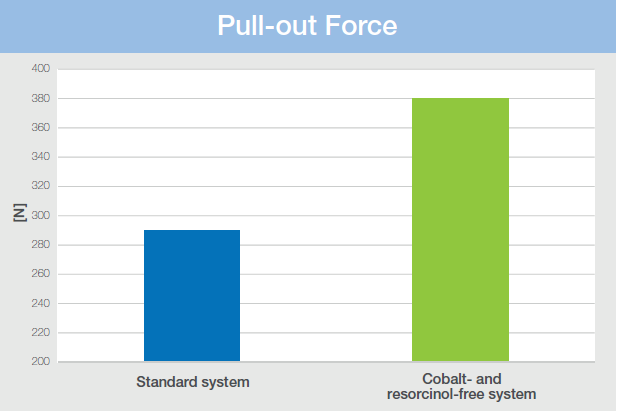

Fig. 2: Pull-out force values according to ASTM D 2229-02

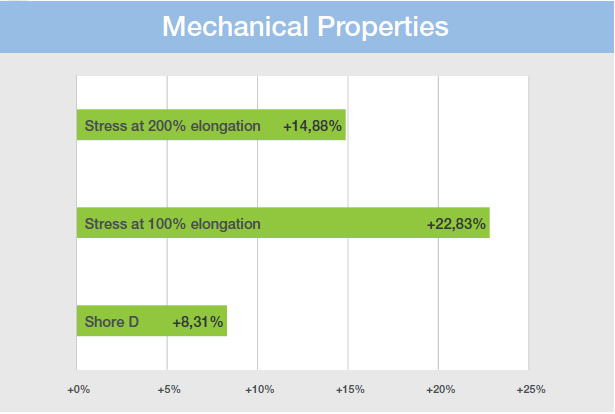

Fig. 3: Improvement of mechanical properties of cobalt- and resorcinol-free system compared to standard system (in percent)

- Exemplary Mechanical Data of TP 1862 in a Steel-cord Adhesion Mixture

Scheme 1: Elimination of cobalt and resorcinol from adhesion mixtures by application of TP 1862.

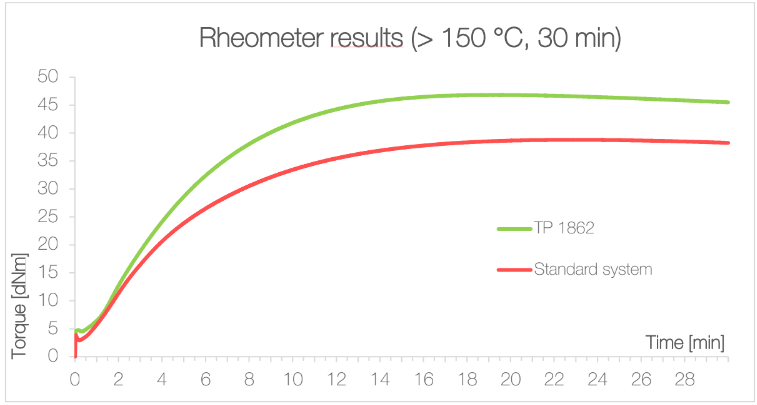

Reference [phr] Resorcinol & Cobalt free [phr] NR 100 NR 100 N326 55 N326 55 Stearinic acid 2 Stearinic acid 2 Silica 15 Silica 15 TMO 1 TMO 1 Oil 4 Oil 4 Resorcinol 3 TP 1862 8.5 Cobalt-salt 0.75 ZnO 6 HMMM 4 HMMM 4 Sulfur 6 Sulfur 6 DCBS 0.6 DCBS 0.6 TBBS 0.9 TBBS 0.9 Scheme 2: Rheometer data for TP 1862 at T > 150 °C, t = 30 min.

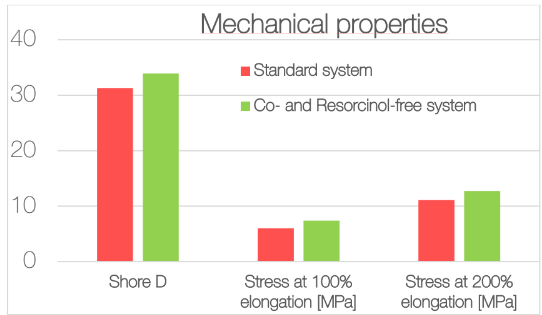

Rheometer curves for steel-cord adhesion mixtures that contain TP 1862 show significantly higher torque values - which indicates a high crosslink density. Mechanical tests reveal outperforming values as well, e.g., in stress elongation or in Shore D.

Scheme 3: Shore D value and stress elongation for steel-cord adhesion mixture vulcanized with TP 1862

.

.

Picture 1: Granules of TP 1862.

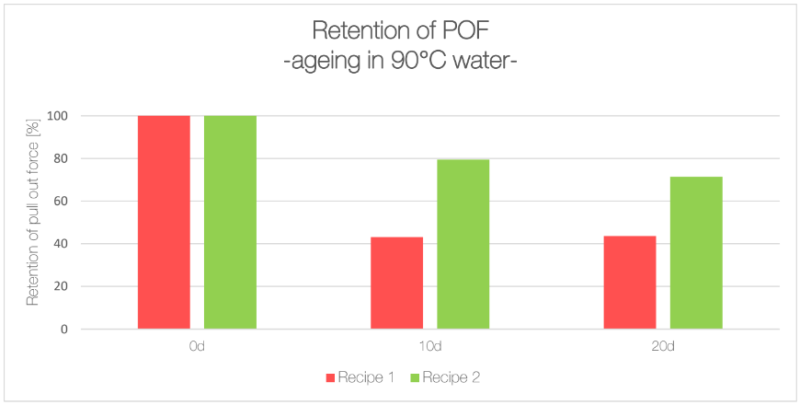

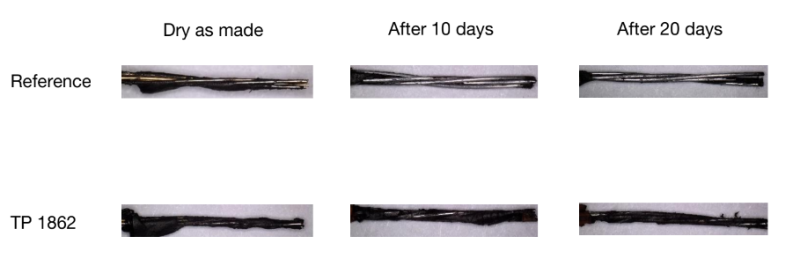

Scheme 4: Retention of pull-out-force (POF-values) for standard formulation (recipe 1) and steel-cord adhesion mixture vulcanized with TP 1862 (recipe 2) in aging test

Strong adhesion strength is a primary prerequisite for durable tires. Vulcanization with TP 1862 leads to steel-cord adhesion mixtures with much higher retention of pull-out-force (POF-values) in aging tests.

.

Picture 2: Retention of pull-out-force (POF-values) for standard formulation (recipe 1) and steel-cord adhesion mixture vulcanized with TP 1862 (recipe 2) in aging test.

Safety & Health

- Health and Safety Data

- Brueggemann TP 1862 is classified as hazardous according to the valid CLP-Regulation (H400 and H410, very toxic to aquatic life – with long lasting effect). Before commencement of operations a risk assessment must be carried out. To this end, and for ensuring the necessary protective measures, the associated safety data sheet must be noted. In addition, it must be checked whether the stated identified uses resp. specified application conditions in the safety data sheet are met.

- The aforementioned remarks are deducted from the European legal system. Deviating or additional regulations in other legal systems must be observed accordingly when using the product.

Packaging & Availability

- Country Availability

- Packaging Type

- Regional Availability

- Standard Packaging

- Brueggemann TP 1862 is available in a 25 kg cardboard box with a PE-inliner.

- Special packaging is available on request.

Storage & Handling

- Shelf Life

- 12 months

- Storage Conditions

If stored properly in unopened bags (25°C/ protected from light) Brüggemann guarantees a shelf life of at least 12 months.