Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Chemical Name

- Plastics & Elastomers Functions

- CAS No.

- 1314-13-2

- EC No.

- 215-222-5

- Technologies

- Chemical Characterization

- Brueggemann Zinc Oxide RAC is an active zinc oxide, which is produced by a special precipitation process.

- Due to the gentle thermal treatment and its chemical origin, Brueggemann Zinc Oxide RAC provides excellent vulcanization properties.

Features & Benefits

- Materials Features

- Product Highlights

- Activator for sulfur and thiuram vulcanization

- Ideal for slow reactive systems like EPDM

- Excellent cost/performance ratio

- Optimal composition for vulcanization

- Reduction of heavy metal content up to 50 % in comparison to conventional systems

Applications & Uses

- Markets

- Compatible Polymers & Resins

- Plastics & Elastomers End Uses

- Product Applications

Particularly suitable for activation in sulfur-cured vulcanization of all common rubber types (e.g. NR, SR, IR, SBR or NBR).

Properties

- Physical Form

- Appearance

- White, yellowish powder

- Typical Properties

- Heavy Metals

| Value | Units | Test Method / Conditions | |

| Zinc Content (as ZnO) | min. 92 | % | — |

| Specific Surface Area | min. 50 | m²/g | — |

| Bulk Density | min. 450.0 | kg/m³ | — |

| Value | Units | Test Method / Conditions | |

| Heavy Metal Content | max. 100 | ppm | — |

Regulatory & Compliance

- Certifications & Compliance

- Integrated Management System

L. Brüggemann GmbH & Co. KG, Heilbronn, Germany, manufactures this product under the following certificates and assessments:

- DQS certified management system ISO 9001:2015 (Cert.-Reg.-No. 001499 QM15 UM15)

- DQS certified management system ISO 14001:2015 (Cert.-Reg.-No. 001499 QM15 UM15)

- DQS attested energy management system ISO 50001:2011 (Cert.-Reg.-No. 001499 EMSt14)

- BG-RCI certified implementation of OSHAS 18001:2007 and ILO-OSH 2001 (Reg.-No. RCI 08-010-21-01)

- EcoVadis with gold status attested principles of sustainability

Technical Details & Test Data

- Exemplary Mechanical Data for Brueggemann Zinc Oxide RAC in a Rubber Matrix

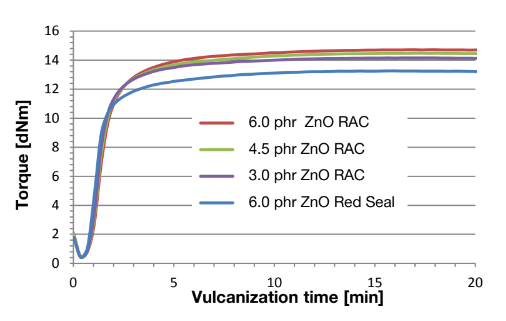

Scheme 1: Rheometer data for an NBR rubber mixture at 170°C.

Brueggemann Zinc Oxide RAC belongs to so called active zinc oxides and is well established in the rubber industry since many years. Due to its high specific surface area of ≥ 50 m2/g it enables outstanding mechanical properties - even with decreased amounts compared to conventional zinc oxides.

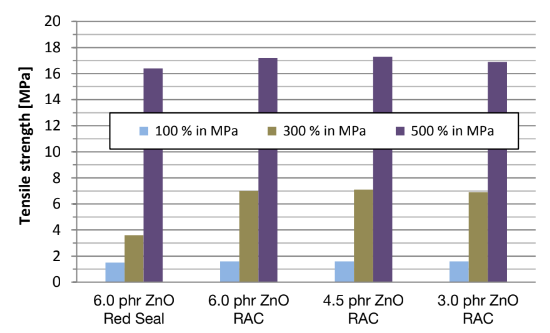

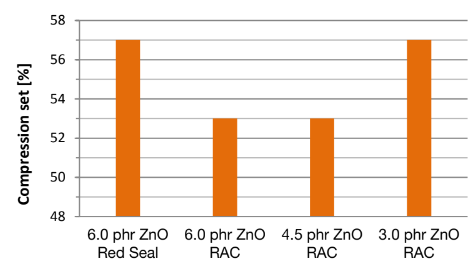

Rheometer curves for rubber mixtures that contain Zinc Oxide RAC show significantly higher torque values - which indicates a high crosslink density. Mechanical tests reveal according values, e.g. in tensile strength and compression set studies.

Scheme 2: Tensile values at 100%, 300% and 500% for NBR-testing bars, vulcanized with Brueggemann Zinc Oxide RAC and ZnO Red Seal.

Scheme 3: Compression set values after 24h at 100°C for NBR-testing bars, vulcanized with Brueggemann Zinc Oxide RAC and ZnO Red Seal.

[phr] Perbunan NT 3945 100 N333 30 Zinc Oxide 3-6 Stearinic acid 1 Vulkanol OT 10 Vulkanox 4010 NA 1.5 Sulfur 1.5

Safety & Health

- Health and Safety Data

- Brueggemann Zinc Oxide RAC is classified as hazardous according to the valid CLP-Regulation (H400 and H410, very toxic to aquatic life - with long lasting effect). Before commencement of operations a risk assessment must be carried out. To this end, and for ensuring the necessary protective measures, the associated safety data sheet must be noted. In addition, it must be checked whether the stated identified uses resp. specified application conditions in the safety data sheet are met.

- The aforementioned remarks are deducted from the European legal system. Deviating or additional regulations in other legal systems must be observed accordingly when using the product.

Packaging & Availability

- Packaging Type

- Standard Packaging

- Brueggemann Zinc Oxide RAC is available in 25 kg paper bags or 1.000 kg big bags.

- Special packaging is available on request.

- Standard delivery form is 40 bags/1,000 kg on a CP-1 pallet.

- International Listings

Brueggemann Zinc Oxide RAC is listed in the national inventories of all major markets.

Storage & Handling

- Shelf Life

- 24 months

- Storage Conditions

If stored properly in unopened bags (25°C/ dry) Brüggemann guarantees a shelf life of at least 24 months.