Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Chemical Name

- Composite Materials Functions

- Plastics & Elastomers Functions

- Technologies

Features & Benefits

- Materials Features

- Product Highlights

Polypropylene compatibilizer excellent for coupling PP to inorganic materials, PP to polar polymers and other uses.

Created directly through reaction instead of extrusion, our CAI-PP-30 compatibilizer is ideal for coupling reinforcing layers like glass filler or PP-to-metal adhesion. Superb Izod & Charpy performance, notched and unnotched.

This compatibilizer also features significantly decreased VOC than traditional MAH grafted modifiers.

- Benefits

- Functions as a coupling agent between polypropylene and reinforcing materials, such as glass fibers and inorganic fillers.

- Achieve compatibility between polyolefins and more polar polymers capable of interacting with maleic anhydride for alloying, recycling or co-extrusion purposes.

- Improves polypropylene-to-metal adhesion.

- Excellent unnotched Izod and Charpy impact performance in filled resin.

- Excellent notched Izod & Charpy impact performance in filled resin.

- Improve tensile and flexural strength in filled compounds.

- Less VOC compared to traditional MAH grafted modifiers.

Applications & Uses

- Compatible Polymers & Resins

- Compatible Reinforcements

- Plastics & Elastomers Processing Methods

- Application Examples

- Compatibilizing most effective in binding PP to reinforcing layers like glass/inorganic fillers or metal adhesion.

- Achieve compatibility between polyolefins and more polar polymers capable of interacting with maleic anhydride for alloying, recycling or co-extrusion purposes.

Properties

- Specifications

| Value | Units | Test Method / Conditions | |

| Density (at 23°C) | 0.90 - 0.92 | g/cm3 | — |

| Melt Index (at 190°C, 2.16kg) | 30 - 80 | g/10min | — |

| MAH Content | High | % | — |

Technical Details & Test Data

- Comparison Between MAH-g-PP Obtained by Extrusion, and CAI-PP-30

Item Test condition CAI-PP-30 PP-G-MAH

(low odor competitor)PP-G-MAH

(Regular 1#)PP-G-MAH

(Regular 2#)Volatile Content 150°C for 10min 0.15% 0.14% 0.20% 0.25% Grafting Level Acid-base titration 0.81% 0.83% 0.72% 0.86% VOC Test Standard * 50g, 23°C*24h 2.5 2.5 3.0 3.0 VOC Test Standard * 50g, 40°C*24h 3.0 3.0 3.5 4.0 VOC Test Standard * 50g, 80°C*24h 4.0 4.0+ 4.5 4.5 * PV 3900, Odor Test (VW)

- Application Example - Long Glass Fiber Reinforced PP (20% GF)

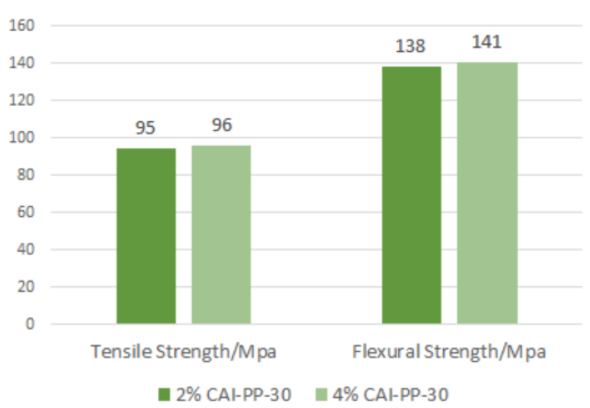

Tensile and Flexural Strength

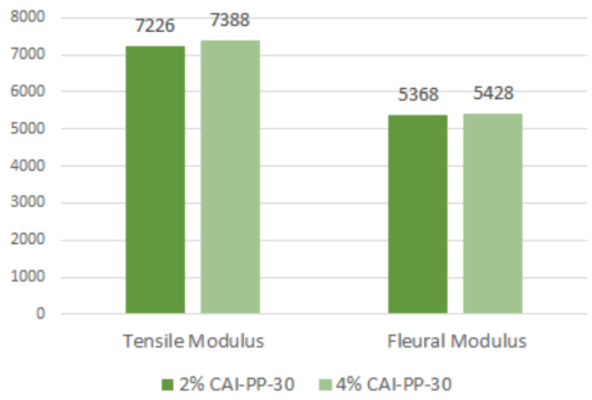

Tensile and Flexural Modulus

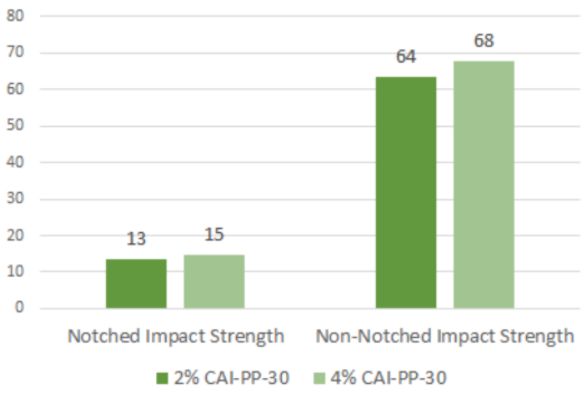

Impact Strength (KJ/m2)

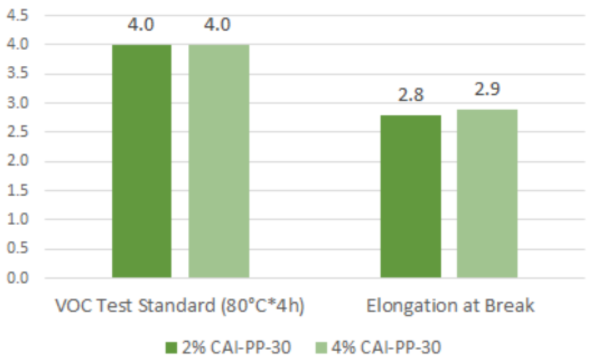

VOC Test Standard and Elongation at Break

Packaging & Availability

- Packaging Information

- 25kg/package, transported as common chemicals.

Storage & Handling

- Storage

- Keep in a dry, cool place. Storage temperature should not exceed 45°C.

- To prevent cross-linking, please clean the twin screw immediately after use.