Knowde Enhanced TDS

Identification & Functionality

- Base Oil Type

- Product Type

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- Ready-to-Use Product Features

- Product Highlights

- Features

- Forms stable emulsions in various water hardness up to 1000ppm

- Low foaming tendencies

- Medium oil content

- Free of chlorine, secondary amines, phenols,

- nitrates, PCB’s, and heavy metals

- Product performance is constant and machine remains clean

- Reliable in-service performance and long sump life

- Heavy-duty machining capability

- Ease of disposal and friendly work environments

Applications & Uses

- Applications

- Application Area

- Compatible Substrates & Surfaces

- Applications

CITGO CITCOOL SS-HD is recommended for general machining including thread cutting and forming, deep hole drilling and boring, reaming, and grinding of cast irons, ferrous alloys and stainless steels, free cutting aluminum alloys, oil resistant plastics, and other non-ferrous materials.

Properties

- Appearance

- Amber Fluid

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Dilution (5% in DI water) | Semi-Translucent | — | — |

| Specific Gravity 60/60 | 1.02 | °F | ASTM D 1298 |

| Mineral Oil Content | 20.0 | % | — |

| pH (3% concentration) | 9.5 (5%) | — | — |

| Defoaming mL (5% in 50 ppm water) | Nil (60 sec.) | — | — |

Technical Details & Test Data

- Material Compatibility

P-Steels Highly Recommended M-Stainless Steel Highly Recommended K-Cast Iron Recommended N-Non-ferrous Highly Recommended Might stain some sensitive aluminum alloys. e.g. 2000 and 7000 series - METAL MACHINABILITY GROUPS

Machining Operation Non-Ferrous,

Soft Metals^{(2)}Nickel Alloys,

Nitralloy

Steels, Cast

Irons and Alloy

Steels (up to

200 Brinell)Stainless Steels,

‘‘Monel’’ Metals,

Cast Irons and

Alloy Steels

(200 to 300

Brinell)Titanium Alloys, High

Tensile Nickel Alloys,

Austentic Stainless

Steels, Tool Steel

and High Tensile

Alloy Steels (300 to 400 Brinell)Turning, Boring, Milling, Forming, Drilling, Sawing 5-7% 5-7% 8-10% 8-10% Tapping, Thread Rolling, Reaming, Screw Cutting,

Broaching5-7% 5-7% 8-10% 8-10% Gear Shaping, Form and Thread Milling, Shaving,

Hobbing, and Trepanning5-7% 5-7% 8-10% 8-10% Internal and External Grinding, Form and

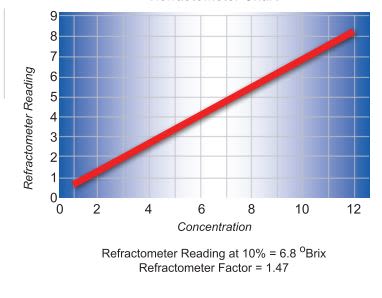

Thread Grinding5-7% 5-7% 5-7% 5-7% Stamping 5-20% 5-20% 5-20% 5-20% - Refractometer Chart

Packaging & Availability

- Packaging Type