Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Chemical Name

- Cleaning Ingredients Functions

- CAS No.

- 70084-87-6

- EC No.

- 615-058-8

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- HII Features

- Product Highlights

- Reduce fabric creasing

- Easier ironing

- Color protection

- Repairs damage to natural fibers

- Improves fiber gloss and smoothness

- Protection against thermal damage caused by heat treatment e.g. tumble drying and ironing

- Moisture retentive and highly substantive conditioning agent

- Cost effective

- Easy to formulate – water soluble

- No problems with 'build-up' on fabrics

- Vegetable protein derived

- Fabric protection

- Fabric Protection

Coltide HSi is an advanced copolymer of hydrolysed wheat protein and silicone. Recommended for use in fabric care, Coltide HSi combines the unique functionalities of both molecules in one ingredient. Coltide HSi is proven to be effective in improving the ‘easy iron’ properties of fabric conditioners, and has shown wrinkle reduction, fiber protection and conditioning benefits.

Applications & Uses

- Markets

- Applications

- Home Care Applications

- I&I Cleaning Applications

- Recommended Uses & Known Applications

- Fabric conditioners / softeners

- Easy-iron sprays

- Permanent press / starch sprays

- Speciality wool / Mohair care products

- Fine / delicate wash detergents

- Laundry detergents - suitable for liquids, powders & tablets

- Formulation Guidelines

Coltide HSi can be easily incorporated into detergent systems. Due to its polyanionic nature Coltide HSi may display some incompatibility with a limited number of cationic surfactants. Recommended usage levels are 0.25-1.0% active depending on the desired effect.

- Applications

- Fabric detergents

- Fabric conditioners

- Auxiliary fabric products

Properties

- Physical Form

- Odor

- Characteristic

- Appearance

- Clear viscous liquid

- Soluble in

- Water

- Dispersible in

- Water

Regulatory & Compliance

- Certifications & Compliance

Technical Details & Test Data

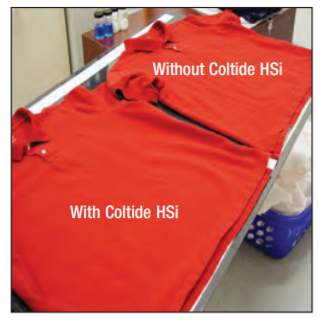

- Crease Reduction

As seen in Image 1 below, Coltide HSi reduces creasing.In this test, we compared polo shirts have been washed in domestic washing machines along with a ballast load before being treated with a commercial fabric conditioner and tumble dried. The shirt on the left hand side had Coltide HSi added to the fabric conditioner at 4%.The shirt on the right hand side did not.

Image 1: Effect of Coltide HSi on wrinkle reduction through the conditioning cycle

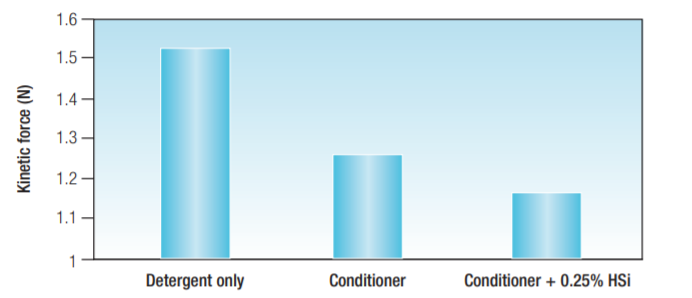

Figure 1 shows that Coltide HSi significantly reduces the coefficient of friction of the cotton swatches, thereby improving the ease of ironing. Coltide HSi was also compared to silicones, which are commonly used as ‘easy iron’ additives to conditioners. In order to achieve comparable performance Coltide HSi was required at only 0.25% (as supplied), resulting in a cost effective alternative to silicones.

Figure 1: Reduction of force required to pull domestic iron across cotton swatches using Coltide HSi

To further evaluate the ease of ironing claim a panel study was conducted, in which panelists ironed four shirts – some washed with detergent and fabric softener treated with Coltide HSi (0.5g in a 35mL dose of fabric conditioner) and some washed with detergent and using 35mL dose of fabric conditioner, all were then tumble dried.

The panelists were recorded ironing the shirts and the contact times between the iron and the fabric were calculated for each shirt ironed. It was found that Coltide HSi reduced the required contact time between the iron and the shirt from 114 seconds to 95 seconds – a 19 second reduction in ironing time for a typical white work shirt. This gives an overall 19% reduction in ironing time and so provides a very strong easier ironing claim.- Looking Good–Keeping Young

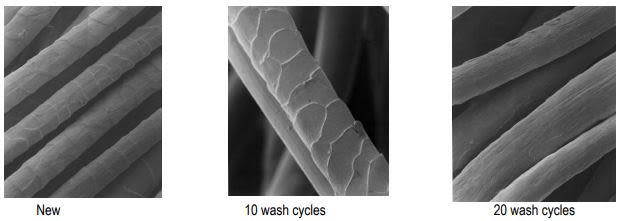

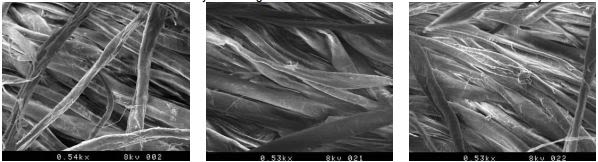

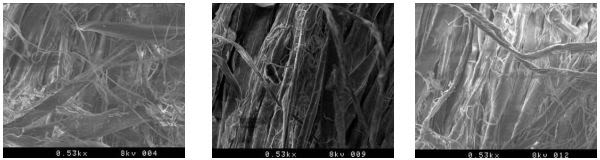

Repeated washing and drying of clothes damages fibers and garments. Cotton fibers will change in appearance from a smooth fiber with a kidney shaped cross section to one which shows a high degree of fibrillation. Similarly, woolen fibers will lose their characteristic cuticle structure following a number of wash cycles.

Image 3: Fibrillation of cotton fibers after repeated wash cycles without CRODA Coltide HSi

Image 4: Loss of cuticle structure of wool fibers after repeated wash cycles

This can be seen on a microscopic level but is also evident on a macro scale due to the deterioration in the feel and strength of the garment along with a perceived lightening in color (due to greater light scattering) and poorer handle.

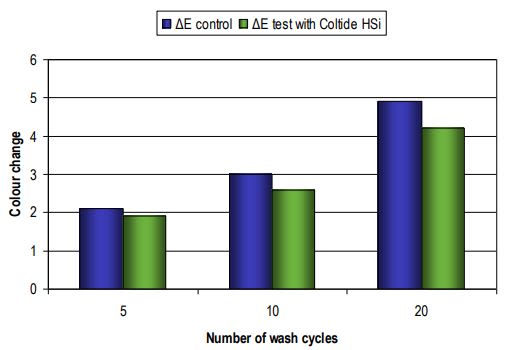

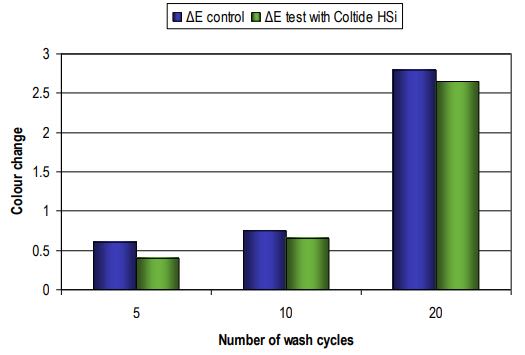

Tests on blue denim jeans and black cotton t-shirts have demonstrated the ability of Coltide HSi to help prevent color fade on garments. The blue jeans and black t-shirts were washed along with ballast with a commercially available laundry detergent and then treated with a commercial fabric conditioner before being tumble dried.

The control garments were treated with the standard commercial products whereas the test garments included Coltide HSi at 4% as supplied. Color change was assessed using a reflectometer to give a quantitative result; However, all assessors could see a difference in the color of the garments.Garments treated with products using Coltide HSi stayed darker and kept their color longer.

Image 5: Visual difference in blue denim jeans after 20 wash cycles. Control (left) vs Test, containing Coltide HSi (right)

Color fade of blue denim jeans:

Figure 2: Color fade of blue denim jeans

Color fade of black t-shirts:

Figure 3: Color fade of black cotton t-shirts

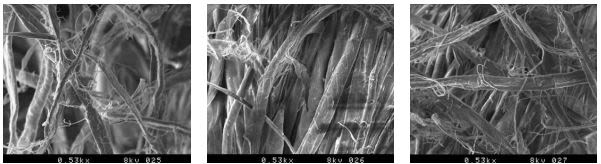

The blue denim jeans were studied using a scanning electron microscope (SEM) to evaluate the condition of the fibers after 20 wash cycles. Images 6 and 7 have been taken of the waistband of the jeans.

Image 6: SEM of jeans waistband washed with detergent and fabric softener with Coltide HSi after 20 wash cycles

Image 7: SEM of jeans waistband washed with detergent and fabric softener alone after 20 wash cycles

Notice the high level of fibrillation evident in Image 7 compared to Image 6.

SEM images were also taken of the fabric at the leg seam of the jeans and these are presented in Images 8 and 9.

Image 8: SEM of jeans leg seam washed with detergent and fabric softener with Coltide HSi after 20 wash cycles

Image 9: SEM of jeans leg seam washed with detergent and fabric softener alone after 20 wash cycles

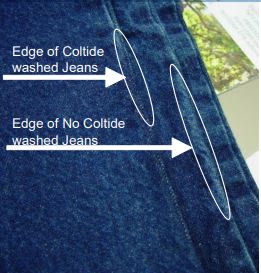

Once again it can be seen very clearly that there is a high level of fiber damage in Image 9 that has been prevented by the inclusion of Coltide HSi within the fabric softener. The difference in appearance can be seen without the use of an SEM. Image 10 shows the leg seam of the denim jeans used in the test and overlays the Coltide HSi treated jeans with those washed in fabric softener alone.

With Coltide HSi, the leg seam retains a deep blue color. Without Coltide HSi the fabric along the leg seam has a worn, light colored appearance in the same area, caused by the wearing and fibrillation of the fibers

Image 10: Comparison of fabric damage along leg seams of denim jeans washed with and without Coltide HSi.

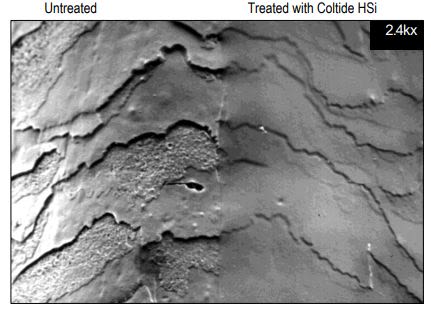

In the following studies Coltide HSi was evaluated on human hair as a model for natural fibers eg: wool due to the similarity between wool and human hair follicles and fibers. Both wool and hair consist of protein-based structural materials and possess cuticular surfaces. The performance of Coltide HSi on hair is therefore taken as an indication of its expected performance on natural fabrics.

Repeated washing and drying of clothes is known to impair the appearance and feel of natural fabrics in particular. Scientific studies on hair have reproduced the stresses arising from repeated washing and blow drying to measure the physical impact of these processes.

Hair fibers undergo damage in the form of cuticle de-cementation, buckling and cracking. Treatment with Coltide HSi offers proven protection against such cuticle damage on hair, and as a result may offer similar benefits to natural fibers (Image 11).

Image 11: Visual difference of fiber treated with Coltide HSi

- Coltide HSi Fiber Glossing and Smoothing

To evaluate the conditioning benefits of Coltide HSi when applied from a detergent system, a double-blind sensory evaluation was conducted on human hair using 152 expert panelists. The panelists were asked to compare the gloss and smoothness of hair washed with an anionic detergent system incorporating Coltide HSi. Of the 152 industry professionals surveyed, 114 (75%) preferred the feel of the hair washed with the Coltide HSi formulation.

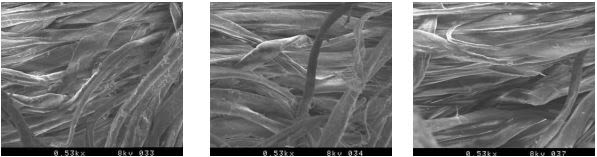

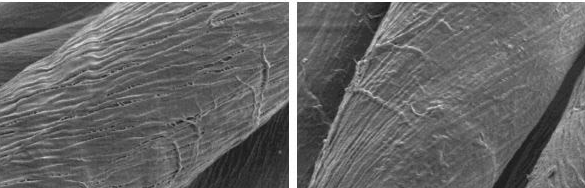

- Fiber and Fabric Moisturizing

Coltide HSi protects fabric and fiber structure by maintaining moisturization of the fibers leading to a reduction in breaking and fibrillation. In these tests, fabrics were washed using Coltide HSi in a detergent formulation and SEM images were taken of the fibers. The results seen in Image 12 show surface damage and a loss of moisturisation in the fibers not protected with Coltide HSi.

Protection at the fiber level reduces breaking and fibrillation of the fibers visible using SEM at higher magnifications.

Image 12: SEM images of fibers washed with a detergent without Coltide HSi (L) and with Coltide HSi (R)- Coltide HSi Substantivity

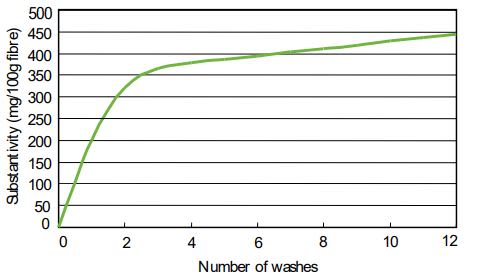

Coltide HSi is highly substantive. Figure 4 shows the substantivity to fibers from repetitive treatments with 2% active solutions of Coltide HSi in 10% active anionic detergent base at pH 7.0.

Coltide HSi has high substantivity with fabric without causing build up: A rapid increase in substantivity is seen for the first two or three treatments followed by a plateau for later treatments. This behavior indicates that, despite the high substantivity exhibited by Coltide HSi, there is no evidence that 'build-up' problems on fabric are likely to occur.

Figure 4: Substantivity of Coltide HSi (2% active aqueous solution in 10% anionic detergent base)

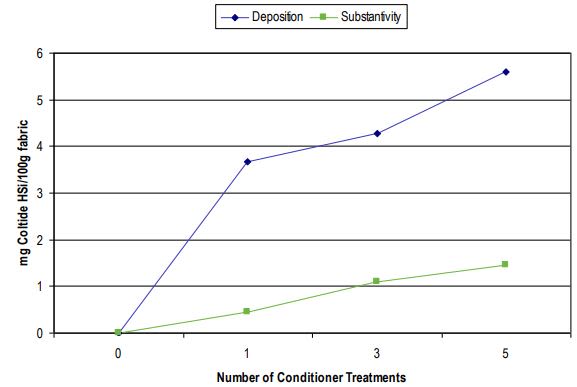

A further study was put in place to emulate European washing conditions. Figures 6 and 7 show the substantivity and deposition to fibers when washed in a commercial laundry detergent, rinsed, and immersed in fabric conditioner solution containing commercial fabric conditioner with only 0.45% radio labeled Coltide HSi.

Table 1 : Deposition of Coltide HSi onto cotton fabric from a European wash

No. of conditioner treatments Deposition (mg Coltide HSi/100g fabric) Mean deposition (mg Coltide HSi/100g fabric) Standard deviation Swatch 1 Swatch 2 Swatch 3 1 12.69* 3.83 3.51 3.67 0.23 3 3.28 5.72 3.83 4.28 1.28 5 5.65 6.91 4.22 5.59 1.35 * Result not included in calculation of mean and SD as considered an outlier

Table 2 : Substantivity of Coltide HSi to cotton fabric after detergent wash under European wash conditions

No. of conditioner treatments Deposition (mg Coltide HSi/100g fabric) Mean deposition (mg Coltide HSi/100g fabric) Standard deviation Swatch 1 Swatch 2 Swatch 3 1 1.33* 0.51 0.38 0.45 0.09 3 1.02 1.12 1.13 1.09 0.06 5 1.44 1.86 1.05 1.45 0.41 *Result not included in calculation of mean and SD as considered an outlier

The deposition and substantivity results in Table 1 and Table 2 are shown together in Figure 5:

Figure 5: Deposition and substantivity of Coltide HSi to cotton from European wash conditions

Packaging & Availability

- Country Availability

- Regional Availability