Knowde Enhanced TDS

Identification & Functionality

- Cleaning Ingredients Functions

- Technologies

Features & Benefits

- Labeling Claims

- HII Features

- Product Highlights

- Proven antistatic performance across a range of substrates.

- Effective at very low inclusion levels.

- Excellent formulation compatibility.

- Biodegradable.

- Streak-free cleaning performance.

- High aqueous solubility, with good pH stability.

- Performance Highlights

Performance in Commercial Formulations

The evaluation of antistatic performance involved measurements of charge decay using a JCI 155 charge decay test unit. The JCI 155 test unit deposits a charge onto substrates and incorporates a fast response fieldmeter to observe, without contact, how quickly this charge migrates away. The JCI 155 charge decay test unit was used to apply a charge of approx. 2000V to various point on the test substrate. The end point voltage was taken as the time taken for the initial charge to dissipate to less than 10% (200V). The performance of Crodastat 400 was tested in several commercial glass cleaning and multisurface formulations and, on 3 different surface types: polyacrylate, polycarbonate and polystyrene).

Prior to the evaluation the surface (approx. 3mm thickness polyacrylate, polycarbonate or polystyrene) was divided into equal sections, thoroughly cleaned with detergent solution, rinsed with hot demineralised water, then solvent cleaned. The test solutions were applied to the plastic surface as follows:

- Approximately 2g of test solution was sprayed onto the surface.

- Using a folded paper towel the surface was wiped with light pressure 20 times in a clockwise circular motion & then with 3 vertical wipes using a separate folded paper towel.

- This was then allowed to condition for at least 1 hour in a humidity controlled environment of 50% humidity and 20°C temperature.

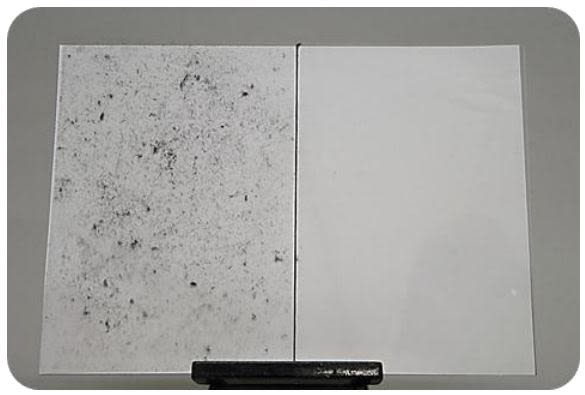

The dramatic difference that Crodastat 400 makes in a standard multisurface cleaning formulation can be seen in Figure 1, where one side of the plastic sheet has been treated with the standard test solution (no Crodastat 400) and one side was treated with the test solution containing 0.4% Crodastat 400.

Figure 1: Effects of using Crodastat 400 in a standard multisurface cleaning formulation

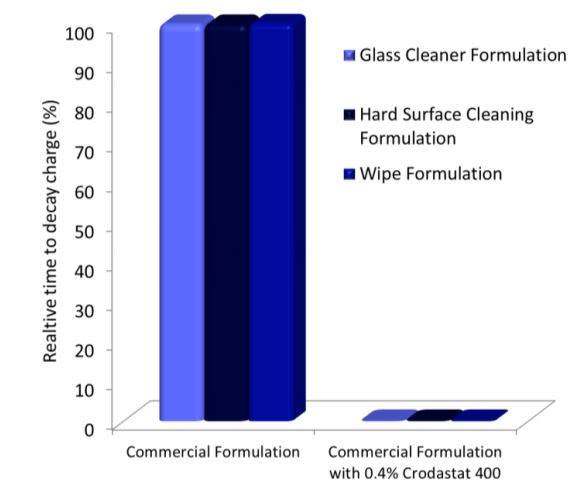

Several different cleaning formulations were tested for antistatic performance, with and without Crodastat 400. It can be seen in Figure 2 that the different commercial cleaning formulations tested had almost no antistatic performance prior to the addition of Crodastat 400, whereas after the addition of 0.4% Crodastat 400 the static build up is reduced to almost nothing. Each product that was tested showed over a 99% increase in antistatic effect, making it less likely to attract dust after the clean.

Figure 2: Antistatic performance of Crodastat 400 in various commercial cleaning formulations

A wide range of commercial cleaning formulations were tested for comparable performance data, with only 40% of the commercial products that had existing antistatic claims showing reasonable antistatic performance, meaning that the charge either did not decay on certain plastics or was very slow to do so. Only 10% showed performance comparable to that of formulations containing 0.4% Crodastat 400.

Performance on Various Surfaces

Further testing was conducted to gage the performance of Crodastat 400 on three different surface types, in commercial glass cleaning formulations. The results in Figure 3 are an average of four commercial glass cleaning products with and without Crodastat 400 on three of the most commonly found plastics in the household: polyacrylate, polycarbonate and polystyrene.

Figure 3: Antistatic effects of Crodastat 400 on different substrates

The charge did not leave the surfaces cleaned with the formulation without Crodastat 400, whereas the charge left the surfaces cleaned with Crodastat 400 in less than 0.05 seconds in every case. Crodastat 400 displayed unbeatable antistatic performance on all surface types tested, with an optimum inclusion level of 0.4%.

Long Lasting Efficacy

Four commercial cleaning products were tested for initial and longer term effects (with pH of the formulations ranging from 3-11). This was using the same test method as above for testing initial cleaning performance and then testing after 2 weeks. The graph in Figure 4 shows the averaged results of the four cleaning products tested on the 3 plastic surface types, as it was found to behave exactly the same on polyacrylate, polycarbonate and polystyrene plastic surfaces.

Figure 4 shows that the commercial products without Crodastat 400 still held static charge on the surfaces after the two week period, whereas with 0.4% Crodastat 400 added the antistatic effect was still apparent and no charge could be built up.

Figure 4: Long lasting effect of Crodastat 400

This durability of performance is particularly relevant for market products claiming long lasting efficacy, which is becoming more and more apparent on products in the surface cleaning market.

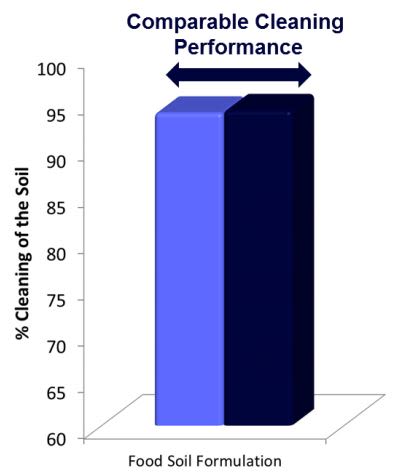

Cleaning Performance

A commercial multisurface cleaning product, currently available on the market, was used to test the effect that Crodastat 400 has on the primary cleaning performance of a product. The product was tested with and without 0.4% Crodastat 400 for comparison. A pre purchased food stained melamine tile (DM-7 Spaghetti mix BV materials) was cleaned with both test solutions on a Gardner scrub tester. The degree of stain removal on each of the tiles was then tested using an X-rite i5 spectrophotometer taking △Y as the reduction in stain color value, the results can be seen in Figure 5.

Figure 5: Testing of Crodastat 400 in commercial cleaning formulation to target food soil stains

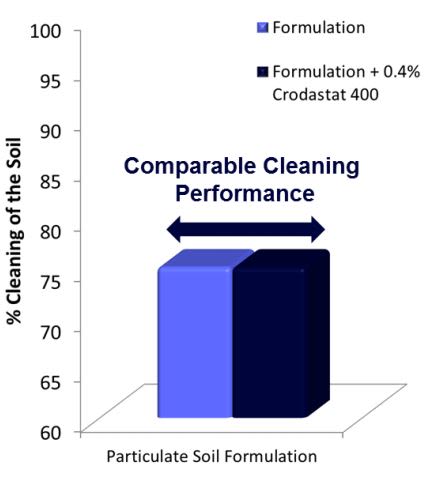

The graph in Figure 6 was produced using the same test method as above, but testing was conducted on a greasy particulate soil, using the frame hard surface cleaning solutions in Table 1.

Ingredients Frame Formulation With crodastat 400 Deionised Water 97.4 97 Natsurf 265 1.2 1.2 Crodastat 400 - 0.4 Sodium Bicarbonate 0.5 0.5 Crodateric LIDP 0.5 0.5 Sodium Gluconate 0.4 0.4 Total 100 100 Table 1: A frame hard surface cleaning solution with and without Crodastat 400 used to generate scrub test data

Figure 6: Testing of Crodastat 400 in a Frame cleaning formulation to target particulate soil stains

The results displayed in Figures 5 and 6 clearly show that Crodastat has no negative effects on the cleaning performance of commercial cleaning formulations, but a very significant increase in antistatic performance can be achieved with low inclusion levels of Crodastat 400.

Foaming Performance

The feel of a formulation on application to a surface is largely determined by the foaming characteristics. To assess the impact that Crodastat 400 has on the foam profile of commercial cleaning formulations, the foam build profiles of one low-foam and one medium-foam commercial cleaning formulation was tested with varying levels of Crodastat 400.

The products were tested at a concentration of 1g/L in deionised water on a Sitafoam R2000 foam tester. The foam build profile was created by agitating the solution at 1200rpm for 10 seconds, then measuring the foam height and repeating this for 20 cycles. The test was then repeated using the same commercial product, but with 0.4% Crodastat 400, to determine any differences in foam profile build.

Figure 7: Effect of Crodastat 400 on foaming in commercial formulations

It can be seen in Figure 7 that the addition of Crodastat 400 into commercial formulations does very slightly increase the foam build profile of commercial formulations, however all inclusion levels of Crodastat 400 tested have excellent antistatic performance and the foaming profile of the commercial formulations is retained.

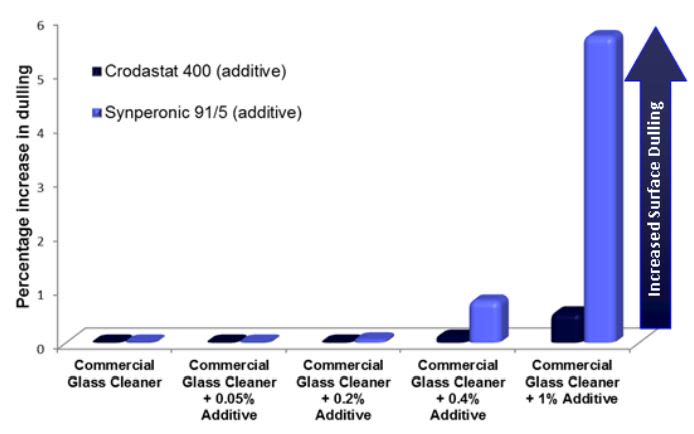

Surface Dulling

Mirrored tiles were used to assess the effect on surface gloss/shine of adding Crodastat 400 to commercial cleaning formulations. The tiles were cleaned in a controlled way, using a commercial streak free window cleaning formulation. The test was then repeated using the same formulation, one with increasing inclusion levels of Crodastat 400 and another with increasing inclusion levels of a standard alcohol ethoxylate additive for comparison.

Gloss measurements were then taken at various points across the mirrored tile and compared to the base gloss readings taken prior to the cleaning. The comparative results can be seen in Figure 8.

Figure 8: Effect on surface shine/gloss of Crodastat 400 vs standard ethoxylate additive

Substrate Compatibility

To determine the compatibility of Crodastat 400 with different surfaces, the test materials listed in Table 2 were submerged in a 5% solution of Crodastat 400 in deionised water, over a time period of four weeks (see Figure 9 for example test set-up). The polyacrylate, polycarbonate and polystyrene represents raw materials used for the manufacture of most plastics found in the modern household, from electrical equipment to fittings and furniture. The iPhone screen represents a more complicated screen, which has been highly engineered.

The initial transmittance through the surfaces at 410 nm was measured using a Jenway 6300 spectrophotometer and then compared to the transmittance readings after 4 weeks. The inclusion level of Crodastat 400 was exaggerated for this test, to represent more contact with the surface than any household product would actually be exposed to in its entire lifetime.

Figure 9: iPhone screen submerged in cleaning solution containing Crodastat 400

Substrate Transmittance at week 0 Transmittance at week 4 iPhone Screen min. 99.5% min. 99.5% Polyacrylate min. 99.5% min. 99.5% Polycarbonate min. 99.5% min. 99.5% Polystyrene min. 99.5% min. 99.5% Table 2: Substrate compatibility testing of Crodastat 400 over a four week period

The results seen in Table 2 confirm that there is no effect on substrate transmittance after 4 weeks of testing, so it can be concluded that there are no compatibility issues observed for Crodastat 400 on any of the tested surfaces.

- Antistatic

- Very low formulation inclusion levels (0.2-0.4%)

- Ideal for concentrated formulations

- Long lasting performance

- Compatible with multiple surface types

- Antistatic

- Very low formulation inclusion levels (0.2-0.4%)

- Ideal for concentrated formulations

- Long lasting performance

- Compatible with multiple surface types

- Summary

Anionic surfactants developed specifically to deal with anti stat problems. Ideal for hard surface cleaners.

Applications & Uses

- Markets

- Applications

- Home Care Applications

- I&I Cleaning Applications

- Use Level

- 0.2-0.4%

- Formulation Guidelines

Formulation Stability

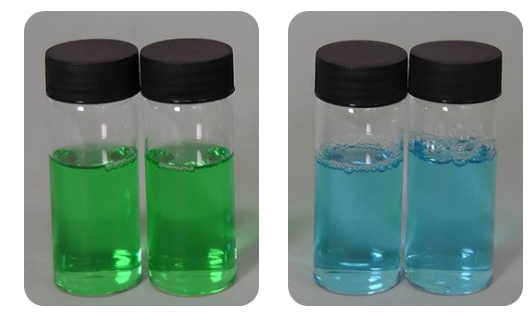

Extensive compatibility trials were conducted on over 10 commercially available hard surface products (from various regions), to assess the compatibility of Crodastat 400 with other ingredients currently used in hard surface cleaning formulations. Crodastat 400 was post dosed at a 1% concentration into a range of commercial cleaning products and stored for 3 months at 5, 20 and 40°C. The appearance and odor of the commercial cleaning products was then compared with that of the original formulation to determine compatibility with Crodastat 400. Figure 10 shows two examples of the formulations tested, with no difference in appearance after 3 months.

Figure 10: Example of stability testing on two commercial formulations after 3 months at 40ºC – standard formulation (left) and formulation with 1% Crodastat 400 (right) in each image.

All formulations were identical in both appearance and odor following the stability testing, indicating that the Crodastat 400 is highly compatible with all ingredients used, including the fragrances and dyes.

Formulating

Crodastat 400 is cold processable and extremely water soluble, making it very easy to formulate with. It can be added at any stage of the manufacturing process, with no impact on the final formulation. It is a liquid product, that is mobile even at extremely low temperatures.

- Applications

- Multisurface cleaners

- Glass/window cleaners

- Specialty hard surface cleaners for high value plastic surfaces (including electronic devices and automotive care)

- I&I cleaning

- Applications

- Surface Care

- Vehicle Care

Properties

- Physical Form

- Soluble in

- Water

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Dynamic Viscosity at 25°C | approx. 400 | mPa.s | — |

| Relative Density at 25°C | approx. 1.1 | - | — |

| Flash Point | min. 149 | °C | — |

| Boiling Point | min. 100 | °C | — |

Regulatory & Compliance

- Certifications & Compliance

Packaging & Availability

- Country Availability

- Regional Availability