Knowde Enhanced TDS

Identification & Functionality

- Chemical Name

- Cleaning Ingredients Functions

- CAS No.

- 61791-12-6

- EC No.

- 500-151-7

- Technologies

Features & Benefits

- Labeling Claims

- HII Features

- Castor Oil Derivatives

The ECO Etocas series are vegetable-derived non-ionic surfactants which find widespread use as emulsifiers, wetting agents, dispersants and lubricants. ECO Etocas surfactants are available as part of Croda’s 100% renewable, 100% bio-based ECO range of surfactants. They are commonly used in such diverse applications as textiles and leather processing, printing inks, household products, metalworking fluids, emulsion polymerisation, paper recycling and other auxiliary industries. ECO Etocas are ethoxylated castor oil. Members within each range have different degrees of ethoxylation (moles) as indicated by their numerical suffix. Members with levels of ethoxylation differing from the standard range may be made available on request, subject to minimum batch quantities.

- Features and Benefits

- 100% Renewable

- 100% Bio-based*

- Reduces reliance on fossil fuel feedstocks

- Manufactured with renewable energy

- Performance identical to petro-based options

- Lower carbon footprint than petro-based versions

- Will be tested for certification to the USDA BioPreferred® Program

- RSPO Supply Chain Certified via Mass Balance**

*Calculated using USDA BioPreferred Method for determining bio-based content which is to be validated by carbon 14 testing (ASTM D6866)

** Products containing palm oil derivatives are RSPO Supply Chain Certified via Mass Balance

USDA BioPreferred is a registered trademark of the U.S Department of Agriculture- ECO Range Multi-layered Renewable Benefits

The ECO range provides multi-layered renewable benefits and value for our customers. Not only will formulators be able to replace petrochemical-based non-ionic analogs while experiencing “zero sacrifice” in performance, they will be able to replace less-effective “natural” market alternatives as well.

Bio-based & Sustainable

- Sustainable palm sourcing, RSPO supply chain certified via Mass Balance†

- Biomass raw material for 100% bio-based ethylene oxide and derivatives

Low Carbon Footprint

- Made using energy sourced from landfill gas and solar energy

- Cradle-to-gate carbon footprint

ECO Range

- 100% bio-based surfactants

Community Benefit

- 30 new full time employees

- Reduced rail freight miles of highly flammable petrochemical EO from the Gulf of Mexico

Green Labeling

- EPA Safer Choice recognized for biodegradability and low toxicity

- USDA BioPreferred® third party certification of C14 measurements

- Emulsion Characteristics

Table 2 indicates the quality of emulsions produced for ECO Etocas 30 at 25ºC when 1% surfactant is combined with 9% oil/solvent in deionised water under normal stirring conditions.

The emulsion characteristics judged were:

1. Ease of dispersion of the surfactant/solvent mixture in water at 25ºC

2. The particle size of the resulting emulsionSurfactant ECO Etocas 30 Aliphatic hydrocarbon solvent Good Castor oil Poor Mineral oil 25cS at 25ºC Fair Isopropyl myristate Good Rape methyl esters Good Table 2: Emulsification characteristics of ECO Etocas Products

- ECO Range

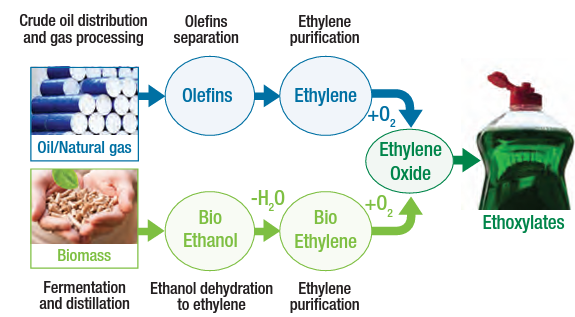

ECO Etocas is manufactured using ethylene oxide derived from bio-ethanol, resulting in 100% renewable surfactants with performance identical to petro-based options. These 100% bio-based products eliminate the need to choose between high performance and fully renewable ingredients. By using an alternative route to ethylene oxide with bioethanol from biomass sources, it significantly increases the bio-based content of ethoxylated products and reduces reliance on fossil fuels. Additionally, ECO Etocas is manufactured with high levels of renewable energy. Sustainability informs and guides our development strategies and is an integral part of our business. ECO Etocas addresses the consumer demand for more sustainable products and aids our customers in meeting their own sustainability goals, while delivering high performance products to the market.

- 100% Bio-based ECO Range

Sustainability is in our DNA. It is integral to everything we do. From the raw materials we source and the way we use them, to the ingredients we create, we believe in being a responsible company. We are pleased to introduce our new ECO range of 100% bio-based surfactants. Over 50 products make up the ECO range made by using bio-based ethylene oxide (EO) which we manufacture from biomass ethanol. Coupling the use of bio-based EO with the high proportion of renewable energy used at the manufacturing plant, leads to a significant reduction in carbon footprint for the ECO product range. Formulators can now access 100% renewable surfactants without sacrificing performance to help meet increasingly demanding sustainability targets.

The new range of ECO surfactants

- 100% renewable

- Performance identical to petrochemicalbased options

- Lower carbon footprint than petrochemically derived ingredients

- USDA BioPreferred®Program third party certification

- RSPO Supply Chain Certified via Mass Balance

- Made using renewable energy

Applications & Uses

- Markets

- Applications

- Home Care Applications

- I&I Cleaning Applications

- Key Application Areas

- Textiles/leather processing

- Printing inks

- Household products

- Metalworking fluids

- Emulsion polymerisation

- Paper recycling

Textiles/leather processing

In synthetic and natural fiber and fabric processing, the ECO Etocas series are useful as dye carriers/solvents, dye leveling and wetting agents, emulsifiers, lubricants, softeners and spin finishes. The intermediate members of the ECO Etocas series are employed as emulsifiers and stabilizers for aliphatic/aromatic solvents, phthalic acid esters, hydrocarbons and other principal dye carriers. In particular, ECO Etocas 40 is recommended as a leveling and wetting agent for disperse dyes on nylon and acetate. ECO Etocas 40 is known to be an excellent emulsifier for oleic acid and oleic acid/mineral oil blends for wool carding oils. They also find application as water-soluble lubricants used in fiber production, texturing, processing and spin finishes. In leather processing ECO Etocas products are used as non-ionic leveling agents to ensure that the applied dye is evenly dispersed through the leather.Printing inks

ECO Etocas products may be used in printing inks as surfactants to improve wetting of pigments and aid ink flow. In duplicator machine inks based on vegetable oils the lower members of the ranges are recommended as emulsifiers and stabilizers. In auxiliary market applications ECO Etocas products are effective vegetable oil emulsifiers in blanket roller cleaners and plate and screen cleaners.Household products

ECO Etocas products can be used in many household product systems as solubilisers, detergents or emulsifiers. The higher molar ethoxylates are effective solubilisers for the fragrances used in household air freshener products, including gels and liquids. ECO Etocas surfactants are recommended as emulsifiers for the preparation of aqueous microemulsion household insecticide products.Metal working fluids

ECO Etocas 30 and 40 are used in cutting fluids and other metal working lubricants where they function as emulsifiers, corrosion inhibitors, dispersants and wetting agents. They may also be used in synthetics and semi-synthetics imparting additional lubricating properties and exhibiting lower foaming characteristics than other non-ionics.Emulsion polymerisation

Non-ionics are generally used in combination with anionic surfactants as they provide stability in the presence of calcium and aluminum ions. The type of ECO Etocas product to be used should be determined by the monomer/solvent type, stability of the monomer emulsion, wetting ability and emulsion particle size/viscosity.Paper recycling

ECO Etocas surfactants may be employed as emulsifiers for fatty acid systems commonly used as de-inking agents in the paper recycling industry.

EmulsificationECO Etocas products are effective emulsifiers for oils, solvents and waxes. The less ethoxylated members of the series (5-30 moles) have HLB values below 12. Above this level of ethoxylation the products exhibit HLB values ranging from 12-15. When selecting an ECO Etocas surfactant using the HLB system, it is necessary to consider the range of materials to be emulsified. In some applications, particularly in more sophisticated systems, a blend of surfactants rather than a single surfactant may be more effective.

Properties

- Physical Form

- Typical Properties

- Solubility

The following table provides data on the solubility/miscibility of the ECO Etocas 30 and 40 series at 10% w/w in a range of common solvents and oils at 25ºC.

Solvent ECO Etocas 30 Water Soluble Acetone Soluble Ethanol Soluble Ethanol/water (50:50) Soluble Oleyl alcohol Soluble Propylene glycol Dispersible Glycerin Insoluble Isopropyl myristate Insoluble Cetostearyl octanoate Insoluble Castor oil Soluble Mineral oil 25cS at 25ºC Insoluble Caprylic/capric triglyceride Dispersible Table 3: Solubility characteristics of the ECO Etocas series

| Value | Units | Test Method / Conditions | |

| HLB Value | 12 | — | — |

Regulatory & Compliance

Technical Details & Test Data

- Improved Bio-based Content

Chemically equivalent to petrochemical-based ethoxylates, Table 1 shows the improvement in bio-based content for key surfactant chemistries when produced using our bio-based EO.

Surfactant Bio-based content

with synthetic EO (%)Bio-based content

with Bio-EO (%)Laureth-6 50 100 Laureth-7 46 100 PEG-40 castor oil 42 100 Polysorbate 20 31 100 Trideceth-9 0 58 C9-C11 + 6EO 0 55 Table 1: Comparison of percentage bio-based content between using petrochemical based EO versus bio-based EO*.

* Calculated using ASTM D6866 which is validated by carbon 14 testing.

† RSPO Grades - Certified sustainable palm oil grades by mass balance (minimum)- Certified Bio-based Content

Our new ECO range helps formulators meet renewability targets. Table 2 lists the BioPreferred bio-based content requirement of a finished formulation under a product category. Replacing petrochemical based surfactants for ECO range products will improve bio-based content of the formulation. All ECO products are being registered on the USDA BioPreferred Program.

Product Category % Bio-based Bathroom Cleaner 74 Bathroom Cleaner 58 Laundry Product 34 Table 2: Examples of USDA BioPreferred product categories and associated minimum bio-based content to be eligible for certification.

- Avoidance of Greenhouse Gas (GHG) Emissions

Converting landfill gas to electricity and steam avoids the release of methane into the atmosphere, which has a global warming potential 25 times greater than CO2 when measured over 100 years. Our use of landfill gas since 2012, combined with the reduction in our usage of natural gas, has led to an aggregate reduction in GHG emissions of close to 1 million tons CO2e. Annually, the amount of avoided emissions is a figure equivalent to our total combined Group 1 and 2 emissions.

- Carbon Footprint of ECO Range

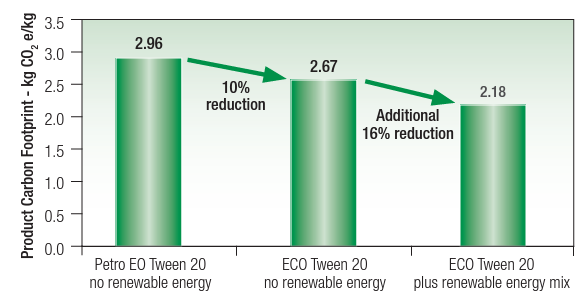

We have used SimaPro software to model the cradle-to-gate life cycle analysis (LCA) of our ECO product families, focused on the climate change impact category, following the technical specification ISO 14067. The high proportion of renewable energy available at Atlas Point, along with the use of bio-based EO, leads to a significant reduction in carbon footprint for a typical ECO product family, when compared to traditional ethoxylates made using petrochemical-based EO and without renewable energy (Figure.4)

Figure 4: Carbon footprint example for Tween 20. Demonstrates the unique carbon footprint reduction moving from petrochemical-based EO to bio-based EO, plus the

plant's use of renewable energy for these ingredients.Δ Atlas Point renewable energy calculated for the 2018 sustainability report.

ΔΔ Group 1 emissions are direct emissions. Group 2 emissions are indirect emissions from the generation of purchased power- Making Ethylene Oxide Sustainable

With increasing consumer demand for renewably sourced and sustainable products, we are pleased to introduce our new ECO range of 100% bio-based surfactants. In recent years, “greener” non-ethoxylated ingredients have been used in the pursuit of more renewable formulations, but the performance has not met the levels achieved when using traditional ethoxylates. With significant investment at our Atlas Point manufacturing site, located in Delaware, USA, our plant is the first of its kind in the US to produce bio-based EO from bio-ethanol (Figure 3). This development enables the production of sustainable and bio-based ethoxylates (Figure.1)

Figure 1: The petroleum and bio-based production pathways of ethylene oxide.

- Renewable Energy at Atlas Point

In 2012, we invested in a renewable energy project at our Atlas Point manufacturing site located in Delaware, USA (Figure 3). This investment saw the installation of a 3.5 mile pipeline from a local landfill site so that we could purchase local landfill gas. The gas feeds two combined heat and power (CHP) units and a multi-fuel boiler to generate electricity and steam for the plant. In 2014, we further invested in solar panels at the site, which reduced our annual carbon dioxide (CO2) emissions by 11,600 tons CO2e. By quarter two of 2020, a third CHP unit will be installed, increasing our capacity for generating electricity and steam from landfill gas and increasing the estimated percentage of the site’s energy being renewably sourced to above 30%.

Packaging & Availability

- Country Availability

- Regional Availability