Knowde Enhanced TDS

Identification & Functionality

- Cleaning Ingredients Functions

- Technologies

Features & Benefits

- Labeling Claims

- HII Features

- Performance Characteristics

Green that stays clean

Effective in acidic, neutral and alkaline pH systems, ModiSurf Clarity can be formulated into a wide range of products and provides a range of consumer benefits such as:

- Effective limescale repellency on glass and polymeric surfaces

- Reduces misting of surfaces

- Environmentally friendly:

- Biodegradable

- High content of renewable raw materials

- No adverse affect on foaming

- Patented

Other ingredients claiming such benefits are based upon polymeric materials that are petrochemical derived and poorly biodegradable. ModiSurf Clarity provides high performance yet is biodegradable and over 60% of the raw materials used in its manufacture are from renewable resources.

ModiSurf Clarity is truly green that stays clean.

Limescale repellency

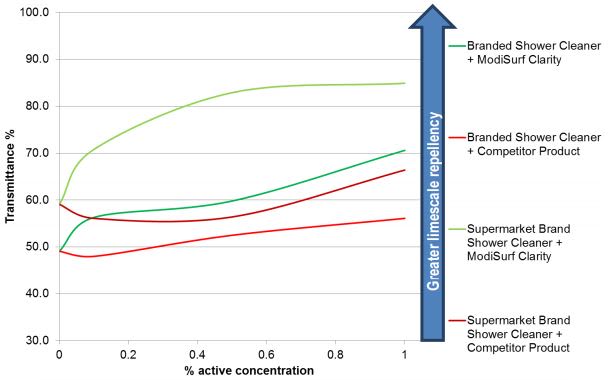

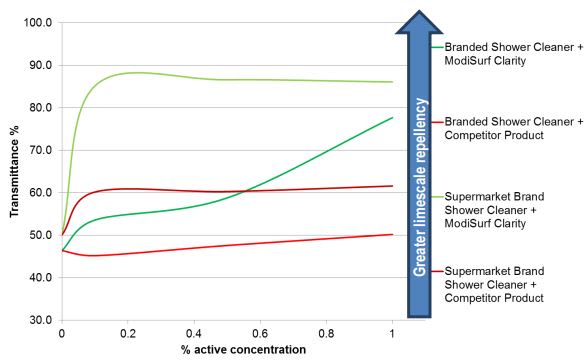

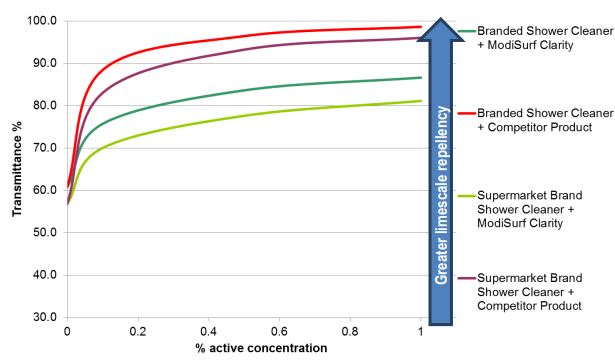

The effectiveness of ModiSurf Clarity in repelling limescale was assessed in commercial formulations and compared to a competitor polymeric surface modification additive.

Both ModiSurf Clarity and the competitor product were added directly to a premium branded shower cleaner formulation and to a supermarket own label formulation at levels of 0.1, 0.5 and 1.0% w/w active basis. Both ModiSurf Clarity and the competitor product were fully compatible with both formulations at all addition levels.In order to test the limescale repellency, new microscope slides were immersed in the solutions for a minimum of one hour, after which the slides were removed, drained and immediately immersed horizontally in a petri dish containing 50ml of fresh, cloudy 1000ppm Ca(HCO3)2 solution, then left overnight. Slides were removed and rinsed by discharging a pipette of water (ca. 2ml) across both the front and back of the slide and then left to dry. The % transmission of each slide in was measured in a spectrophotometer (Jenway 6300) at 403nm, taking three measurements across the surface and recording the average result. Slides made of glass, polyacrylate and polycarbonate were used in order to assess the effect on limescale repellency on a number of substrates.

On polymeric surfaces (polyacrylate and polycarbonate) ModiSurf Clarity outperformed the competitor product on limescale repellency. On glass surfaces, ModiSurf Clarity provided a high level of limescale repellency with similar performance to the competitor product. Overall, ModiSurf Clarity provides a consistently high performance over a wider range of surfaces then the competitor product evailuated.

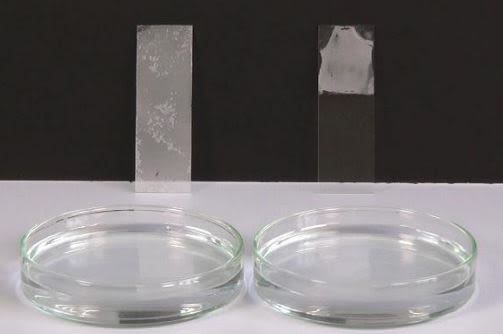

Figure 1: Difference in limescale repellency from slides half treated with shower cleaner formulation with ModiSurf Clarity (right) and shower cleaner alone (left)

The difference made by ModiSurf Clarity can be seen here a glass slide has been dipped in a shower cleaner formulation with and without ModiSurf Clarity. In both cases only the bottom half has been treated. The slides are then immersed in a solution of calcium bicarbonate before removing and drying.

Limescale repellency on polyacrylate

Figure 1: Limescale repellency of ModiSurf Clarity versus competitor product on polyacrylate substrate

Limescale repellency on polycarbonate

Figure 2: Limescale repellency of ModiSurf Clarity versus competitor material on polycarbonate substrate

Limescale repellency on glass

Figure 3: Limescale repellency of ModiSurf Clarity versus competitor product on glass substrate

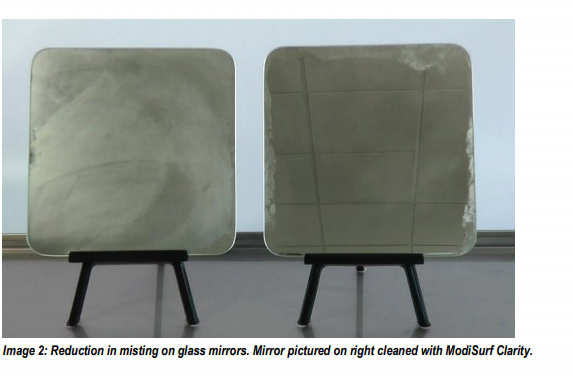

Misting reduction

Glass and mirrors in bathrooms mist up all to easily when a bath or shower is running, however, by incorporating ModiSurf Clarity within the cleaning formulation the level of misting can be greatly reduced.

Mirror tiles were immersed in the cleaning solution for 10 seconds and were then removed and allowed to air dry. Steam was applied from a Steam Tech Garment Steamer across the surface of both tiles for a period of 2 to 3 seconds for each mirror.

Reduction in misting on glass mirrors. Mirror pictured on right cleaned with ModiSurf Clarity

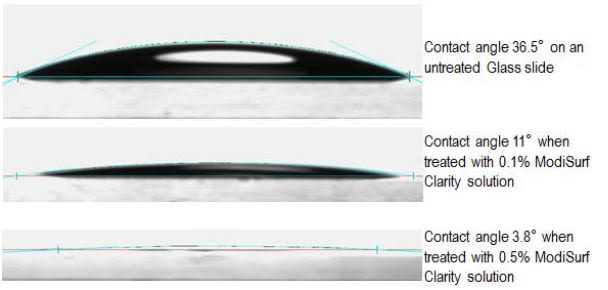

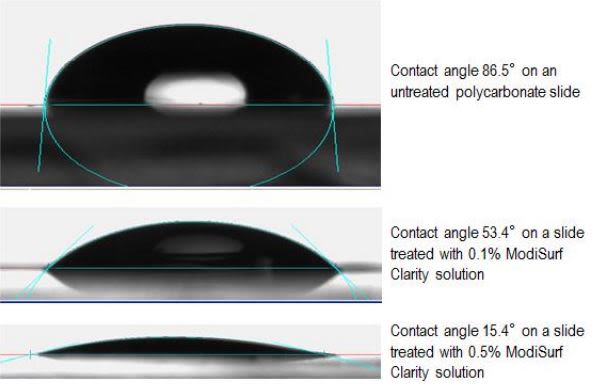

Effect on contact angle

ModiSurf Clarity modifies the nature of hard surfaces in order to make them more hydrophilic. This can be seen through the measurement of the contact angle of water dropped onto glass (picture 3) and polycarbonate (image 4) that have been treated with ModiSurf Clarity.

This change in the hydrophilicity is the reason why ModiSurf Clarity repels soils such as limescale resulting in a surface that is easier to clean and also one that stays cleaner for longer.

Effect on contact angle on glass slides treated with ModiSurf Clarity

Effect on contact angle on polycarbonate slides treated with ModiSurf Clarity

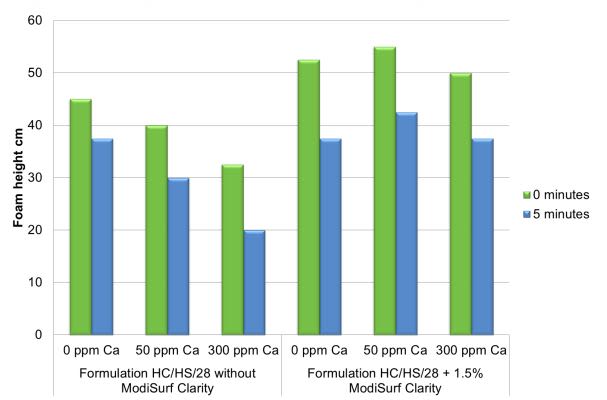

Foaming

ModiSurf Clarity provides foam boosting and stabilization within cleaning formulations. This has been evaluated using the Ross Miles foam test on both commercial products and Croda example formulations.

A market leading branded shower cleaner formulation was tested for foaming characteristics at 0, 50 and 300 ppm Ca2+ water hardness levels. The testing was then repeated on the same shower cleaner containing 1.5% ModiSurf Clarity. The foam height results are shown in Figure 4.

Testing was also carried out on Croda multisurface cleaner formulation HC/HS/28 in order to assess the impact of ModiSurf Clarity upon the foaming characteristics. Again, testing was carried out at 0, 50 and 300 ppm Ca2+ water hardness levels. The testing was then repeated on formulation HC/HS/28 containing 1.5% ModiSurf Clarity. The foam height results are shown in Figure 5.

Figure 4: Ross mile foam height results on branded shower cleaner with and without ModiSurf Clarity at a range of water hardness levels

Figure 5: Ross mile foam height results on Croda formulation HC/HS/28 with and without ModiSurf Clarity at a range of water hardness levels

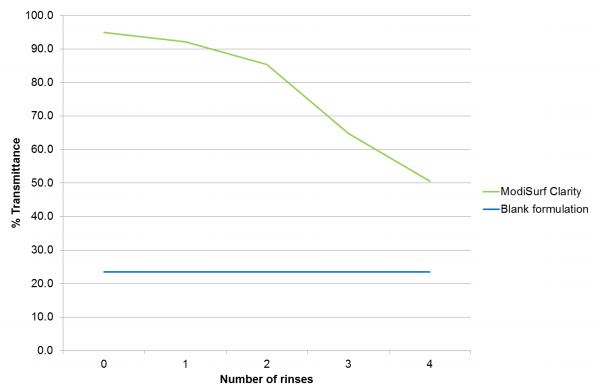

Rinse off resistance

ModiSurf Clarity will remain active on cleaned surfaces for an indefinite period provided that the surface is not cleaned or rinsed. Testing was carried out in order to determine the level of substantivity of ModiSurf Clarity to glass slides and how rinsing will affect the product performance.

Glass slides were treated with a solution of 1% Synperonic 91/5 containing a 1% active level of ModiSurf Clarity for 2 hours. After being removed from the solution the slides were washed with nx1ml of distilled water, n being the amount of times the slide was washed. 1 ml over a glass slide (2.5 cm x 4 cm) is the equivalent of 1.4 liters over a standard shower screen (70 cm x 200 cm).

In order to test the limescale repellency, the slides were immersed horizontally in a petri dish containing 50ml of fresh, cloudy 3000ppm Ca(HCO3)2 solution, then left overnight.

Slides were removed and rinsed by discharging a pipette of water (ca. 2ml) across both the front and back of the slide and then left to dry.

The % transmission of each slide in was measured in a spectrophotometer (Jenway 6300) at 403nm, taking three measurements across the surface and recording the average result.

The results are presented in Figure 6. After 4 rinses the slides treated with ModiSurf Clarity still show significantly better limescale repellency than the blank formulation.

Figure 6: Rinse off resistance of ModiSurf Clarity on glass slides

Applications & Uses

- Markets

- Applications

- Home Care Applications

Properties

- Physical Form

- Appearance

- Clear liquid

- Soluble in

- Water

Regulatory & Compliance

- Certifications & Compliance

Technical Details & Test Data

- Sustainability Criteria

Majority bio-based (95-50%)

Packaging & Availability

- Country Availability

- Regional Availability

Storage & Handling

- Storage and Handling

Storage temperature

“Cool dry” means under cover and out of direct exposure to weather conditions (e.g. sun, rain, snow etc.). The undercover conditions themselves should be such that standing water is not expected. In general terms this means ambient conditions met in a warehouse which is not controlled to ensure a constant temperature and or humidity.

Do not freeze, ModiSurf Clarity is not freeze/thaw stable as supplied.

Material Handling

- Stir material in container prior to use.

- Drums should not be opened prior to use, to avoid ‘skinning’.