Knowde Enhanced TDS

Identification & Functionality

- Cleaning Ingredients Functions

- Technologies

Features & Benefits

- Labeling Claims

- HII Features

- Product Highlights

- Approved natural by Ecocert

- Solubilises a wide range of lipophilic ingredients

- Cold processable and easy to handle

- Ultimately biodegradable

- Does not adversely affect foaming of detergent systems

- Counter-irritant

- Petrochemical free

The chemical functionality of NatraGem™ S140 offers lower interfacial tension from optimized interfacial packing. This allows for micelle sizes small enough not to scatter light, which gives a crystal clear solution. NatraGem™ S140 can solubilise a wide range of oils at levels comparable to other commonly used solubilisers, e.g. Polysorbate 20 and PEG-40 Hydrogenated Castor Oil.

Applications & Uses

- Markets

- Applications

- Home Care Applications

- I&I Cleaning Applications

- Formulation Guidelines

NatraGem™ S140 has been designed to be used as an easy to handle, cold mix solubiliser. It can be incorporated into a formulation in three different ways:

- NatraGem™ S140 and the oil are premixed and added to the water phase with moderate stirring.

- NatraGem™ S140 and the oil are premixed, and then the water phase is added to the premix with moderate stirring.

- NatraGem™ S140 and the oil are premixed, and then twice the quantity of water is added and stirred to give a free flowing solution. This can then be added to the water phase with a minimal amount of stirring. This option is particularly useful if the final formulation has a tendency to foam.

Generally, NatraGem™ S140 will give clearer solutions over time, so formulations may take up to 24 hours to reach full clarity.

- Applications

- Air Care

- Fabric & Laundry Care

- Hard Surface Cleaning

- Industrial & Institutional Cleaning

- Vehicle Care

- Fabric detergents

- Automotive care

Properties

- Physical Form

- Appearance

- Clear pale yellow liquid

- Soluble in

- Water

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Water Content | 20 | % | — |

Regulatory & Compliance

- Certifications & Compliance

Technical Details & Test Data

- Solubilisation Efficiency

NatraGem™ S140 is an easy to handle liquid that can be used in cold process systems with efficient solubiliser to oil ratios. To demonstrate this, the solubilisation effectiveness of NatraGem™ S140 has been compared to two commonly used solubilisers, Polysorbate 20 and PEG-40 Hydrogenated Castor Oil. Polysorbate 20 is a cold process solubiliser that is similar to NatraGem™ S140 in terms of ease of use, whereas PEG-40 Hydrogenated Castor Oil, which is considered a highly efficient solubiliser, requires heating (~50°C) before use and can produce a surfactant gel on mixing with water. The gel needs further heating and stirring to ensure dissolution.

The solubilisers were tested with a wide range of lipophilic substances, including fragrances and essential oils. The base formulation used is shown below:

Lipophilic ingredient: 1%

Solubiliser: 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 12, 15, 20%

[NatraGem™ S140 or Polysorbate 20 or PEG-40 Hydrogenated Castor Oil]Deionised water: upto 100%

The study involved altering the surfactant to oil ratio, until the lowest ratio that produced a clear solution after 24 hours was found. The surfactant to oil ratios evaluated were: 1:1, 2:1, 3:1, 4:1, 5:1, 6:1, 7:1, 8:1, 9:1, 10:1, 12:1, 15:1 and 20:1. For oils that could not be solubilised at 20:1, the result is listed as >20:1 and no further ratios were evaluated.

Pre-experimental information:

- The experiments involving NatraGem™ S140 and Polysorbate 20 were performed at room temperature.

- PEG-40 Hydrogenated Castor Oil was heated to 60°C when mixed with the water, further heating and rapid mixing was used up to 70°C to ensure that the surfactant gel formed had dissolved into the solution.

- Polysorbate 20 and PEG-40 Hydrogenated Castor Oil are both 100% active. NatraGem S140 is 80% active, so the surfactant to oil ratio is also shown as 100% active for a fair comparison.

The results in Table 1 show that NatraGem™ S140 has the lowest surfactant to oil ratio on 11 occasions, as opposed to Polysorbate 20 and PEG-40 Hydrogenated Castor Oil, which are the most efficient on only 6 and 4 occasions respectively.

Lipophile % Surfactant required to solubilise 1% of lipophile NatraGem™ S140 Polysorbate 20 PEG-40 Hydrogenated Castor Oil 80% active 100% active 100% active 100% active Fragrances - CPL Aromas Fruity 3 2.4 5 6 Rose Fresh 20 16 8 8 Apple Fresh >20 - 10 8 Sicilian Lemon 15 12 6 12 Lavender 20 16 7 6 Lemon Peel 20 16 9 10 Mandarin & Coriander 10 8 12 10 Peach Leaf 15 12 7 10 Pear Blossom & Kiwi 12 9.6 7 10 Aloe & Lilac Fabric 20 16 7 7 Pure Force Fabric 12 9.6 20 12 Lilac & Cotton Flower Fabric 15 12 12 12 Fresh Air Fabric 15 12 8 9 White Tuberose Fabric 15 12 5 4 Grapefruit & Green Tea 15 12 7 7 Mint 20 16 8 6 Essential Oils Bergamot Oil 4 3.2 7 12 Citronellol 8 6.4 7 12 Clove Stem Oil 12 9.6 10 15 Lavender Oil 10 8 10 10 Lemon Oil 10 8 10 12 Limonene 5 4 8 15 Organic Eucalyptus Radiata Oil 8 6.4 4 5 Organic Roman Chamomile Oil 3 2.4 8 5 Tangerine Oil Brazil 4 3.2 9 5 Frequency solubiliser was most efficient 11 6 4 Table 1: A comparison of solubiliser to oil ratios for NatraGem™ S140, Polysorbate 20 and PEG-40 Hydrogenated Castor Oil with a number of different lipophilic materials

NatraGem S140 within Detergent Formulations

When NatraGem™ S140 is used in a detergent base the surfactant to fragrance/oil ratio can sometimes be reduced. Table 2 shows the surfactant level required to solubilise 1% of selected fragrances within water, compared to the level required within either a bath and shower cleaner (HC/HS/25) or a 1% solution of nonionic surfactant (Synperonic™ 91/5) in water.

NB. Ratio listed is as supplied not active content

Fragrance Level of surfactant (%w/w) in a water only solution (Table 1) Detergent Base Reduced level of surfactant (%w/w) required to solubilise 1% of lipophile in a detergent base Pure Force Fabric* 12.0 1% non-ionic surfactant 10.0 Bath and Shower cleaner 3.0 Sicilian Lemon* 15.0 1% non-ionic surfactant 8.0 Bath and Shower cleaner 5.0 Peach Blossom and Kiwi* 12.0 1% non-ionic surfactant 8.0 Bath and Shower cleaner 3.0 Mandarin and Coriander* 10.0 1% non-ionic surfactant 8.0 Bath and Shower cleaner 3.0 Suppliers:- *:CPL Aromas Table 2: Surfactant to fragrance ratios can be reduced for some fragrances when used within a detergent base

- Efficacy Studies

Impact on Foaming

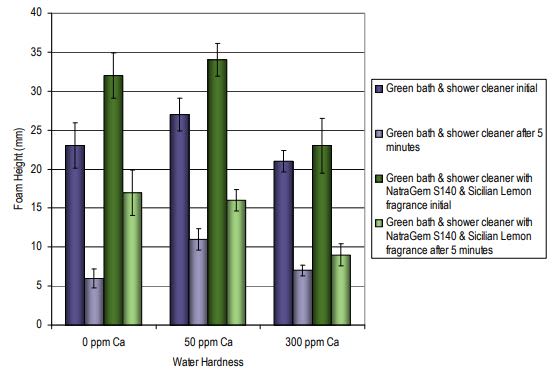

The impact on foaming of NatraGem™ S140 was investigated using the bath and shower base formulation (HC/HS/25), with and without 1g/L NatraGem™ S140 and fragrance in three different water hardness levels. The Ross Miles test was used, with foam height in mm being measured initially and after 5 minutes.

The results in Figure 1 show that NatraGem™ S140 can boost and stabilize foaming. The effect and its extent is dependant on the system and the level of NatraGem™ S140 required.

Figure 1: Ross Miles foam height comparisons of a detergent with and without the NatraGem™ S140 and fragrance

Figure 1: Ross Miles foam height comparisons of a detergent with and without the NatraGem™ S140 and fragranceCounter-Irritancy Properties

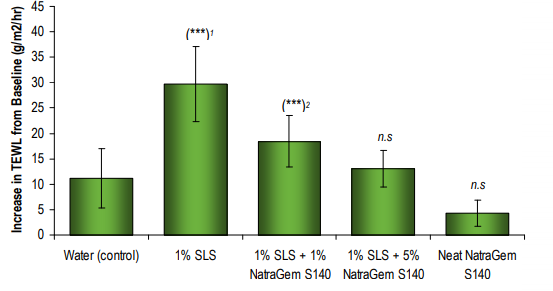

NatraGem™ S140 has been proven to mitigate the irritancy effects of 1% sodium lauryl sulfate (SLS) in water, when patch tested on human skin. In order to demonstrate this excellent counter-irritancy effect, a study was carried out on 12 volunteers to measure Trans-Epidermal Water Loss (TEWL) and skin inflammation. Testing was carried out on the forearm of panelists, in a temperature and humidity controlled environment.

The products tested were:

- Water (used as a control)

- 1% SLS in water (w/w)

- 1% SLS + 1% NatraGem™ S140 in water (w/w)

- 1% SLS + 5% NatraGem™ S140 in water (w/w)

- Neat NatraGem™ S140

Basal TEWL and inflammation (using a Laser Doppler) readings were taken, and then equal amounts of each product were applied to filter paper before being applied to the skin and occluded for 24 hours. The patches were removed one hour prior to the TEWL and inflammation readings being taken again. All test sites were randomized.

The results of the TEWL readings are shown in Figure 2 and clearly illustrates that the SLS significantly disrupts the skin barrier, leading to an increase in water loss through the skin. The addition of 1% NatraGem™ S140 to 1% SLS significantly reduces this water loss, whilst the addition of 5% NatraGem™ S140 to 1% SLS lowers the water loss to show equivalence to that of water alone. Neat NatraGem™ S140 is shown to have no effect on water loss through the skin.

Figure 2: TEWL results of human patch testing to show counter-irritancy effects of NatraGem™ S140 with SLS

Figure 2: TEWL results of human patch testing to show counter-irritancy effects of NatraGem™ S140 with SLS(***)1: significance vs. water p<0.001

(***)2: significance vs. SLS p<0.001

n.s: not significant vs. waterThe results of the inflammation readings are shown in Figure 3, which demonstrates that 1% SLS significantly increases inflammation compared to the water control. There is, however, no significant increase in inflammation when 1 and 5% NatraGem™ S140 was added to 1% SLS. Neat NatraGem™ S140 also had no effect on the skin inflammation.

Figure 3: Inflammation results of human patch testing to show counter-irritancy effects of NatraGem™ S140 with SLS and correlating images

(***)1: significance vs. water p<0.001

n.s: not significant vs. waterPhotos below in Figure 4 are taken from the human patch test study to show how the counter-irritancy benefits of NatraGem™ S140 with SLS can also be seen by human eye.

Figure 4: Photos from the human patch study to visually show the counter-irritancy benefits of NatraGem™ S140 with SLS

Figure 4: Photos from the human patch study to visually show the counter-irritancy benefits of NatraGem™ S140 with SLS

Packaging & Availability

- Country Availability

- Regional Availability