Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Cleaning Ingredients Functions

- Technologies

Features & Benefits

- Labeling Claims

- HII Features

- Product Highlights

- Outstanding foam control

- Excellent rinsing properties

- Improved wetting of surfaces

- 100% bio-based

- NatraSense™ LF8 gives a reduction in the contact angle of water on a series of common kitchen surfaces including glass, ceramic, stainless steel and plastic, which ultimately results better wetting of the surface and faster drying.

- It has also been shown to give a reduction in the amount of undesirable residue left on glass when dipped in hard water and soil solutions. Independent automatic dishwasher (ADW) testing by Eurofins demonstrates that NatraSense™ LF8 easily matches the performance of traditional petrochemical-based low foam alkoxylates.

- As a rinse aid, it leaves low residues, reduces filming and dishware retains a sparkling shine.

- Formulators can enjoy the cleaning performance of high foaming, multifunctional surfactants such as alkyl polyglucosides, but in applications that demand a low foaming formulation.

- Low Foam Rinse Aid

- 100% bio-based foam reduction agent

- Reduced water contact angle

- Better surface wetting

- Faster drying

- Excellent rinse aid action

- Reduction in residues and filming

- Functions

- Surface Modifiers

- Wetting

Applications & Uses

- Markets

- Applications

- Home Care Applications

- I&I Cleaning Applications

- Application pH Range

- 3-10

- Formulation Guidelines

- NatraSense LF8 gives a cloudy dispersion at 0.1% w/w in water.

- It can be hydrotroped into aqueous formulations where required.

- Addition as a defoamer into surfactant formulations typically gives a clear solution.

- Recommended pH of formulations 3-10, however more specific acidic formulations should be checked for stability on an individual basis.

Formulation Examples

Rinse Aids

- Green Ready to Use Rinse Aid (HC/DW/14)

- Green Dilutable Rinse Aid (HC/DW/15)

- Classic Rinse Aid (HC/DW/16)

Low Foam Cleaners

- Green Low Foam All Purpose Cleaner (HC/HS/82)

- Green Low Foam I&I Dilutable Cleaner (HC/HS/83)

- Green Low Foam APG Glass Cleaner (HC/HS/84)

- Applications

- Automatic dishwashing

- Low foam hard surface cleaning

- Household and I&I cleaning

- Applications

- Surface Care

- Dishwash

- Vehicle Care

- Bottle Washing

Properties

- Physical Form

- Insoluble in

- Water

Regulatory & Compliance

- Certifications & Compliance

Technical Details & Test Data

- Efficacy Studies

Outstanding Foam Control

Low foam is desirable in certain applications such as automatic dishwashing or cleaning of industrial equipment as excess foam can hinder the cleaning process. For example where fluids are pumped around a machine, rinsing of large surfaces or in the dishwasher as foam acts as a cushion to the water jets.

Controlling or eliminating foam from a formulation reduces the residues left behind. Not only is the cleaning process improved, but less water is required for rinsing, improving the environmental profile overall.

Foam Control of Surfactants

In order to assess the foam control performance of NatraSense LF8, aqueous stock solutions of surfactants were made up at 1 g/L, to which NatraSense LF8 was added at 0.1 g/L (10% of the total surfactant concentration).

The foaming characteristics of the surfactant solutions, with and without inclusion of NatraSense LF8, were tested using the SITA Foam Tester R2000. The machine doses 250 mL of the test solution, stirs for 10 seconds and automatically measures the foam height. This is repeated 20 times in order to build up a graph of how much foam is generated (foam volume, mL) as the solution is repeatedly stirred (over 20 readings). This process is repeated 3 times for each test solution to generate an average of the foam building.

Benefits of a 100% bio-based alkyl polyglucoside in a low foam application

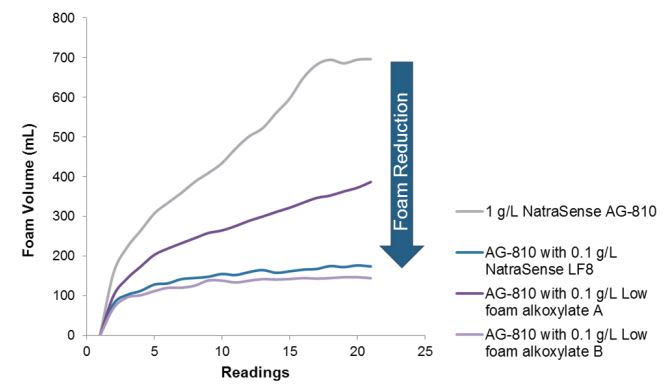

NatraSense AG-810 is a green, multi-functional surfactant used in many cleaning formulations. In an aqueous solution at 1 g/L it generates a high volume of foam, as shown in figure 1, reaching 700 mL by the end of the 20 readings. However, addition of 0.1 g/L of NatraSense LF8 to this solution consistently reduces the final foam volume to less than 200 mL, a reduction of 75%. Generally a solution which produces 200 mL of foam under these conditions is classed as low foam and is suitable for low foam applications.

Figure 1: Defoaming of a 1 g/L aqueous solution of NatraSense AG-810: NatraSense LF8 vs. low foam alkoxylates at 0.1 g/L additions

The defoaming performance of NatraSense LF8 was compared to two conventional defoamers (figure 1), referred to as low foam alkoxylate A and B throughout, added at 0.1 g/L to the 1 g/L aqueous solution of NatraSense AG-810. NatraSense LF8 provides comparable or improved foam control to conventional alkoxylate defoamer chemistries, with low foam alkoxylate A reducing the final foam volume of NatraSense AG810 by 44%, NatraSense LF8 by 75% and low foam alkoxylate B by 79%. This highlights that NatraSense LF8 can be used as an alternative to conventional petrochemical ingredients.

High performance surfactant cleaning in low foam applications

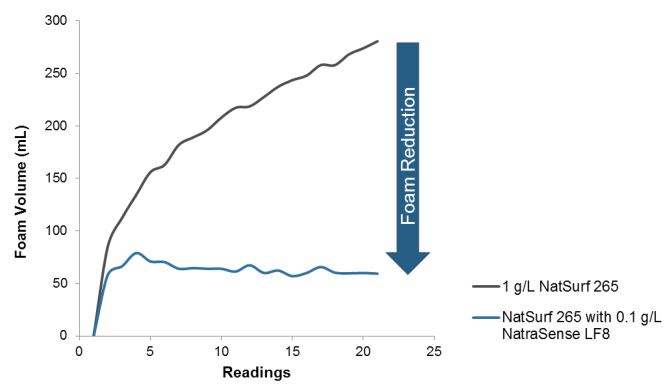

NatraSense LF8 has been shown to reduce the foam volume of a number of other surfactants such as a 1 g/L aqueous solution of NatSurf™ 265 (figure 2), a high performance non-ionic surfactant, where the final foam volume was reduced by 80% with addition of 0.1 g/L of NatraSense LF8.

Figure 2: Defoaming of a 1 g/L aqueous solution of NatSurf 265 using 0.1 g/L of NatraSense LF8

Foam Control of Formulations

In addition to testing the defoaming performance of NatraSense LF8 on surfactants alone, the foam control performance was investigated in full formulations.

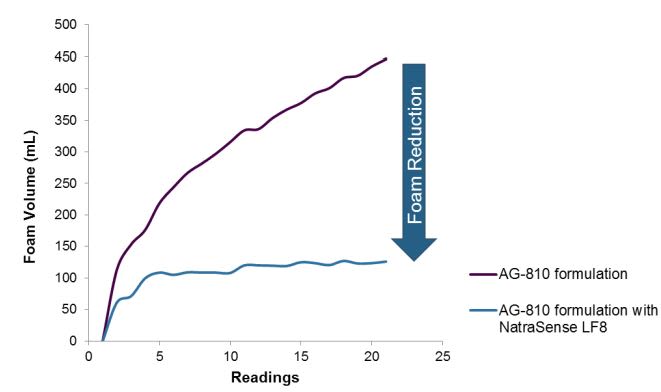

NatraSense AG-810 Window Cleaner Formulation

Low foam is desirable in window cleaners as it reduces the risk of foam residues marking the glass surface. A NatraSense AG-810 based window cleaner formulation was prepared with and without inclusion of NatraSense LF8 (see formulation section HC/HS/84, the level of NatraSense LF8 included was 10% of the total surfactant level in the formulation). The window cleaner formulation was added to water for foam testing such that NatraSense AG-810 was at a concentration of 0.5 g/L.

Inclusion of NatraSense LF8 in the window cleaner formulation reduced the final foam volume by 72%, shown in figure 3.

Figure 3: Comparison of the foam volume of a NatraSense AG-810 window cleaner formulation with and without inclusion of NatraSense LF8

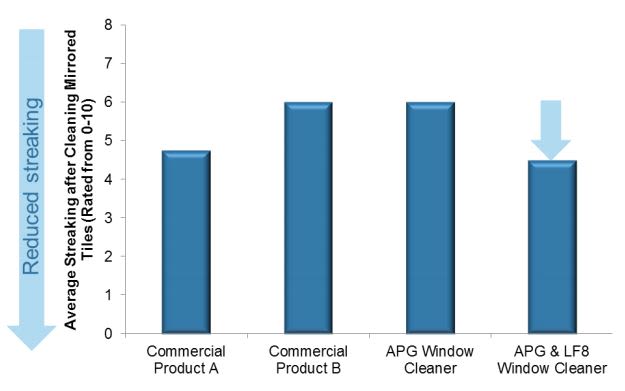

To ensure that there was no negative impact of the cleaning performance of the window cleaner formulation with inclusion of NatraSense LF8, the efficacy and streaking of the formulation was tested using an adapted CSPA method (DCC-09 glass cleaners). Mirror tiles were soiled with synthetic sebum and cleaned using a Sheen Wet Abrasion Scrub Tester, comparing the window cleaner formulation with and without NatraSense LF8, and two commercial products. The mirror tiles were randomized and visually assessed by panelists for both streaking and cleaning performance (efficacy of the formulation).

Streaking of the formulations on the mirror tiles was visually rated on a scale of 0-10, where 0 indicates no streaking and 10 high streaking (figure 4). The window cleaner formulation with inclusion of NatraSense LF8 showed a reduction in streaking when compared to the formulation without NatraSense LF8 and both commercial products.

Figure 4: Results of a panel test visually assessing the streaking of mirror tiles after cleaning with different window cleaner formulations

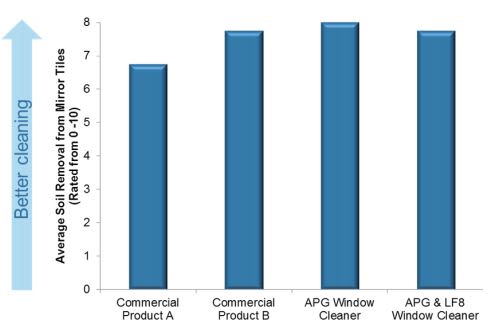

Cleaning performance of the formulations was again visually assessed by the panel on a scale of 0-10, where 0 indicates poor cleaning of the mirror tiles and 10 indicates excellent cleaning of the mirror tiles (figure 5). Inclusion of NatraSense LF8 in the NatraSense AG-810 window cleaner formulation not only reduced the final foam volume by 72%, but also gave no significant loss in cleaning performance when compared to the formulation without NatraSense LF8, and was found to be comparable or show an improvement over commercial products A and B.

Figure 5: Results of a panel test visually assessing the cleaning performance of a NatraSense AG-810 window cleaner formulation with and without NatraSense LF8, at removing sebum from mirror tiles compared to two commercial products A and B

NatraSense LF8 is an outstanding foam control agent, and can be used to significantly reduce the foam volume of multi-functional surfactants such as APGs, and formulations, with no detrimental effect on the cleaning performance or properties of the formulation. It has been shown that NatraSense LF8 can be used as a biobased alternative to alkoxylates for improved or comparable foam control, and will allow formulators to realize the benefits of using multi-functional surfactants in formulations which require low foam.

Automatic Dishwasher Rinse Aid Performance

Excellent Rinsing Performance

NatraSense LF8 provides excellent performance as a rinse aid additive, visibly reducing streaking of glassware and kitchenware, prevents limescale build up, has low build up on the surface itself and imparts high shine retention to kitchenware.

Low foam is important in automatic dishwashers as it prevents the foam from cushioning the water jets, improves cleaning performance as foam residues are reduced, and reduces the volume of water required for rinsing. The low foam characteristic of NatraSense LF8 coupled with its excellent rinsing performance makes it an ideal rinse aid additive for formulators.

Hard Water Residue

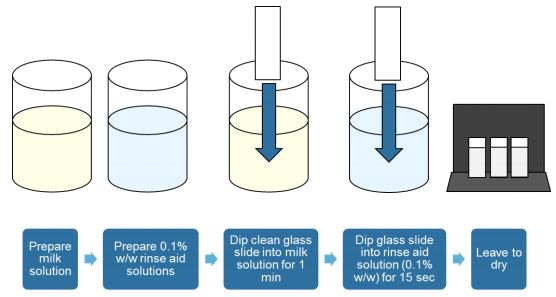

Very hard water was prepared (CaCO3, 10,000 ppm) to accelerate testing and replicate multiple exposure of glassware to limescale. Aqueous solutions of rinse aids were prepared at 0.1% w/w inclusion of NatraSense LF8, low foam alkoxylate B or commercial brand rinse aid hard water (100 ppm). Clean, glass slides or wine glasses were dipped into the hard water for 1 minute, and then dipped into the rinse aid solutions for 15 seconds. The glass was removed from the rinse aid solution and left to dry at room temperature.

Figure 6: Test method comparing the performance of rinse aids in rinsing off limescale (CaCO3, hard water) from glass surfaces

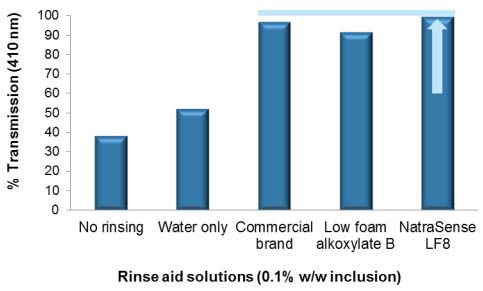

Once dried, the transmittance of visible light (410 nm) through the glass slides was measured, to quantify how much limescale residue was left on the glass surface. A glass slide which had been submerged in the hard water soil only without rinsing was included for comparison, as was a glass slide which had been rinsed with water (100 ppm) only to highlight the effects of the rinse aid additives.

Rinsing with NatraSense LF8 (0.1% w/w) allows 99% of light to pass through the glass slide, thereby removing almost all limescale from the glass (figure 7). This is an improvement over the alkoxylate solution which gave 91% transmission and the commercial brand at 97% transmission.

Figure 7: Transmission values of glass slides treated with NatraSense LF8 vs. a low foam alkoxylate or commercial rinse aid in rinsing of hard water (10,000 ppm)

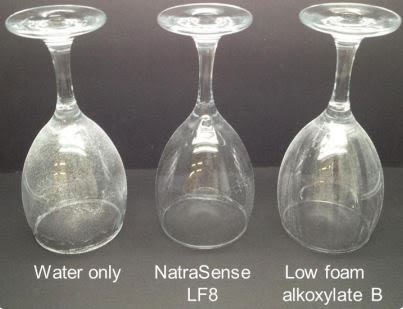

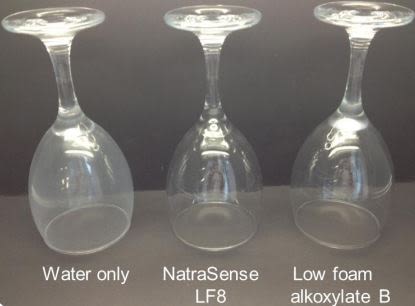

The difference in rinsing performance can be seen in figure 8 below, with NatraSense LF8 providing sparkling glassware with very little limescale residues and streaking, unlike the low foam alkoxylate rinse aid where a number of streaks and limescale staining is visible. A glass rinsed in water alone was included for comparison to show the improvement of using a rinse aid additive.

Figure 8: Visible performance of NatraSense LF8 vs. a low foam alkoxylate (0.1% w/w solutions) in rinsing hard water (10,000 ppm) off glasses compared to a glass rinsed with water only

Milky Soil Residue

A similar test was conducted using a milky soil residue to mimic any protein residues that may stick to glassware after the dishwasher washing cycle.

The soil solution was prepared by adding milk powder (5 % w/w) and sodium hydroxide (5% w/w) to water. Solutions of rinse aids were prepared at 0.1% w/w inclusion of NatraSense LF8, low foam alkoxylate B or commercial brand rinse aid to a diluted version of the milk soil (10% w/w of the milk soil diluted with deionized water). As before, clean glass slides or wine glasses were dipped into the soil solution for 1 minute, and then dipped into the rinse aid solutions for 15 seconds before leaving to dry at room temperature.

Figure 9: Transmission values of glass slides treated with NatraSense LF8 vs. a low foam alkoxylate or commercial rinse aid in rinsing of a milky soil residue

Transmittance data on the glass slides shows that over 98% of light can pass through the slide rinsed with the NatraSense LF8 solution, highlighting that NatraSense LF8 provides excellent rinsing performance, with a slight improvement over alkoxylate chemistries and the commercial rinse aid brand and helps to prevent protein residues sticking to the glass surface.

Figure 10: Transmission values of glass slides treated with NatraSense LF8 vs. a low foam alkoxylate or commercial rinse aid in rinsing of a milky soil residue

The rinsing performance of NatraSense LF8 can be visibly seen on the glassware, with little to no clouding of the wine glass rinsed with NatraSense LF8 compared to the wine glass rinsed in water alone (figure 11).

Figure 11: Visible performance of NatraSense LF8 vs. a low foam alkoxylate (0.1% w/w solutions) in rinsing a milky soil residue off glasses compared to a glass rinsed with water only

NatraSense LF8 shows excellent performance as a rinse aid, visibly reducing streaking and limescale residues on glassware and shows comparable or improved performance over conventional low foam alkoxylate chemistries and a commercial rinse aid brand.

Automatic Dishwasher Testing: Eurofins

Independent automatic dishwasher (ADW) testing conducted by Eurofins, an external testing house, shows that NatraSense LF8 performs comparably as a rinse aid to a low foam alkoxylate and helps to prevent filming on all four surfaces tested (glass, plastic, stainless steel and black plates) retaining shine. NatraSense LF8 is a renewably sourced rinse aid and defoamer, giving 100% bio-based alternative to conventional alkoxylate chemistries.

Eurofins Test Protocol

Miele dishwashers were used as part of the testing, with a standard, consumer relevant load of glasses, plastic boxes, stainless steel cutlery and black ceramic plates. A kitchen ballast soil was introduced into the load at the start of the dishwasher cycle to reproduce typical washing conditions, and a standard reference detergent used in the wash cycle (IEC B). A water hardness of 180 ppm was used throughout the testing. During the rinsing cycle two basic frame solutions containing 15% surfactant, NatraSense LF8 or a low foam alkoxylate B, were manually dosed (3 mL) into the dishwashers.

The dishwasher load was visually assessed under spotlights for both rinse aid action and limescale prevention with shine retention measured using a gloss meter. Rinse aid action was assessed after 1 and 5 cumulative dishwasher cycles at 55°C and limescale prevention after 15 and 30 cumulative dishwasher cycles at 65°C. Shine retention of black plates was measured after each stage.

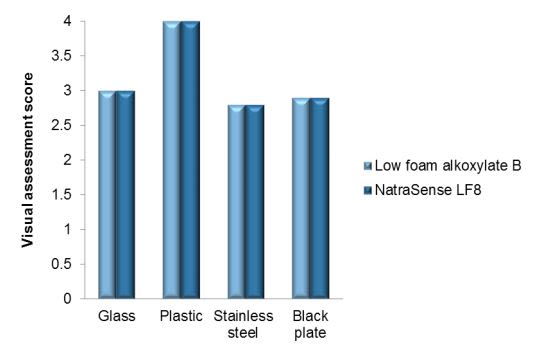

Rinse Aid Action

The visual assessment of film build up on the kitchenware was scored on a scale of 1-4, where 1 is poor with a lot of filming and 4 is excellent with low filming. NatraSense LF8 scores comparably to the alkoxylate in helping to prevent film formation on all of the dishwasher items tested (figure 12).

Figure 12: Visual assessment of filming on four different kitchen surfaces after 5 automatic dishwasher cycles (scale 1 = poor, filming and 4 = excellent, low film)

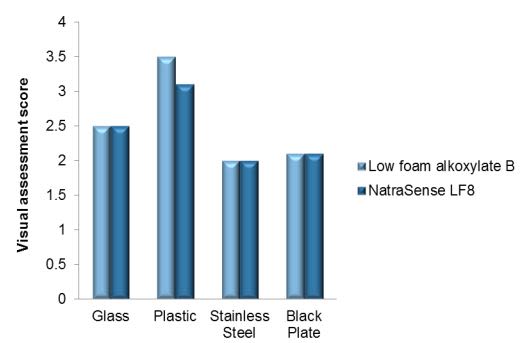

Limescale Prevention

NatraSense LF8 matches the performance of a low foam alkoxylate across almost all kitchenware in preventing and reducing limescale build up and markings (figure 13). The small difference in the result for plastic is not statistically significant.

Figure 13: Visual assessment of limescale prevention on four different kitchen surfaces after 15 automatic dishwasher cycles (scale 1 = poor, filming and 4 = excellent, low film)

Shine Retention

NatraSense LF8 provides excellent shine retention (figure 14) of the black plates in the dishwasher load, retaining 90% shine after 5 cycles and 80% shine after 15 cycles, comparable to low foam alkoxylate B.

Figure 14: Shine retention of black plates following cumulative dishwasher cycles using NatraSense LF8 vs. low foam alkoxylate B

NatraSense LF8 gives improved or comparable performance in reducing streaking and film build up on kitchenware, helping to prevent limescale build up, and allowing items to retain their initial shine. This has been observed both in internal lab testing and external independent testing by Eurofins. NatraSense LF8 can be used as a rinse aid alone in water, and is a green alternative to alkoxylate chemistries.

Formulating into a Rinse Aid

There are three main ways to achieve excellent rinse aid performance with NatraSense LF8, summarized as follows:

- Neat in its concentrated form which could be suitable for solid tabs or balls to be dissolved in the dishwasher cycle (see formulation section HC/DW/14).

- Dissolved in a carrier fluid such as propylene glycol, helping to thin out the viscosity of NatraSense LF8 for dosing e.g. into large containers for I&I (see formulation section, HC/DW/15).

- Formulated into a traditional aqueous based rinse aid formulation, with levels of up to 15% surfactant possible (of which NatraSense LF8 is 10% of the total surfactant level, see formulation section, HC/DW/16).

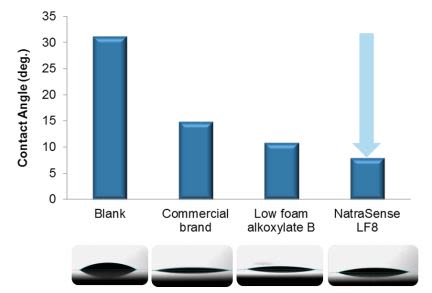

Benefits of Better Wetting

Better wetting of a surface i.e. reduced contact angle, is beneficial to the consumer in many ways, as water will sheet off the surface rather than beading, thereby reducing streaking and spotting, and can ultimately lead to faster drying of the surface.

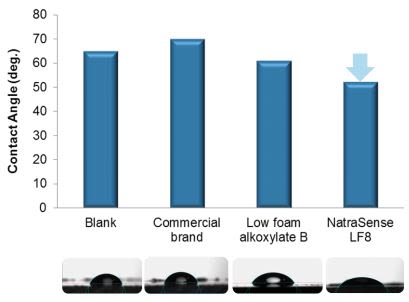

Reduced Contact Angles

To understand more about how NatraSense LF8 provides reduced streaking and spotting on common surfaces, the contact angle of materials treated with NatraSense LF8 were investigated. Different surfaces (ceramic, glass, stainless steel and plastics) were treated with an aqueous solution of NatraSense LF8 (0.5 mL, 0.1% w/w) and wiped dry, before adding droplets of water (20 µL) and measuring the contact angle. The results were then compared to surfaces treated with aqueous solutions of a low foam alkoxylate or a commercial rinse aid brand and also the untreated surface.

NatraSense LF8 reduces the contact angle of water on ceramic by 75% compared to the untreated surface (figure 15) and by 20% on polycarbonate (figure 16).

Figure 15: Contact angle of water on ceramic after treatment with 0.5 mL of a 0.1% w/w solution of NatraSense LF8, an alkoxylate or a commercial rinse aid brand vs. untreated

Figure 16: Contact angle of water on polycarbonate after treatment with 0.5 mL of a 0.1% w/w solution of NatraSense LF8, an alkoxylate or a commercial rinse aid brand vs. untreated.

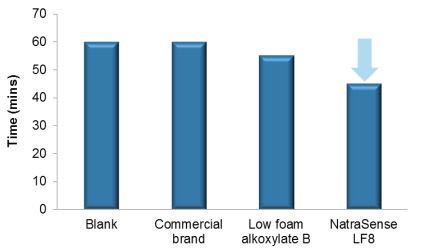

Faster Drying

Faster drying of water from surfaces can be attributed to a lower contact angle, or better wetting, of water on the surface. One example of the benefits of faster drying is in automatic dishwashing, where lowering the contact angle causes water to sheet off the surface reducing spotting and residue markings as well as faster drying of dishware.

NatraSense LF8 has been shown to reduce the contact angle of water on five different surfaces. To follow that, the drying time of water off a glass surface was investigated by treating the surface with an aqueous solution of NatraSense LF8 (0.5 mL, 0.1% w./w), wiping dry, then adding droplets of water (5 x 10 µL) and measuring the evaporation of the water off the surface over time.

Figure 17: Time taken for complete evaporation of water from a glass surface treated with 0.5 mL of 0.1% w/w aqueous solution of NatraSense LF8, a low foam alkoxylate or commercial rinse aid brand vs. untreated surface

NatraSense LF8 shows a 25% improvement in drying time compared to both the untreated surface and the surface treated with the commercial rinse aid brand, and also shows an improvement in drying time over the alkoxylate.

So in addition to providing excellent performance as a rinse aid, visibly reducing the streaking of glassware, preventing limescale build up, and showing a low film build on kitchenware, thereby allowing shine retention, NatraSense LF8 lowers the contact angle of water on surfaces, which can ultimately lead to water sheeting off the surface, reducing spotting and lead to improvements in drying time.

Packaging & Availability

- Country Availability

- Regional Availability