Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Cleaning Ingredients Functions

- Technologies

Features & Benefits

- Labeling Claims

- HII Features

- Product Background

NatSurf 265 offers a distinct combination of excellent dispersing, stabilizing and wetting properties and can be employed as the principal surfactant in cleaning products. This non-ionic alcohol ethoxylate surfactant avoids high viscosities even in ultra-concentrated formulations and has a wide pH tolerance.

The lack of a gel-phase and the rapid dissolution, even in cold water, in combination with the wide range of electrolyte compatibility and solubility, lend to the favorable handling and formulating properties of NatSurf 265. This provides multi-functional benefits, making it an excellent choice for cleaning formulations.

NatSurf 265 provides a new solution to help meet consumers’ growing demands for Home Care products that provide superior cleaning and have eco-friendly label claims without any compromise on product performance

- Product Highlights

- Superior cleaning performance.

- Ideal for highly concentrated formulations

- Fast dissolution at low temperatures.

- Excellent electrolyte tolerance.

- Reduced need for oil solubilisers.

- Improves fragrance solubilisation

- Wide pH compatibility

- No viscosity build up

- Highly versatile surfactant

- Performance Highlights

Bathroom Soap Scum Test

Soap scum is a white film that builds up in showers and bathtubs, and is an insoluble residue of calcium and magnesium soaps which can be difficult for consumers to remove. In order to test the effectiveness of NatSurf 265 on soap scum, the performance was assessed using a Sheen Wet Abrasion Scrub Tester, comparing two bathroom cleaning formulations (see Formulation section); one containing a standard C9-11 5EO alcohol ethoxylate (AEO), and the other one containing an equivalent amount of NatSurf 265 (HC/HS/81). A stearatebased soap scum soil was applied to ceramic tiles which were then baked for a short period of time to leave a hard to remove residue. The tiles were then cleaned and rinsed lightly with tap water (Image 1).

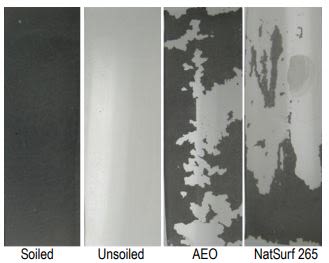

Image 1: Photographs of ceramic tiles with soap scum applied, before and after cleaning with two bathroom cleaner formulations

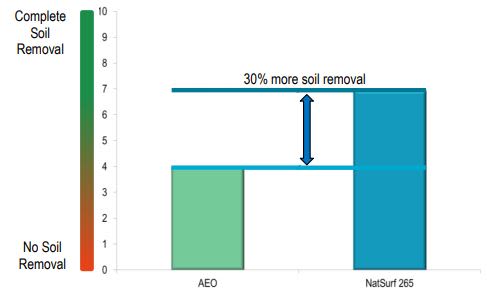

Once dry, the tiles were randomized and assessed by panelists, who rated the tiles from 0 to 10, where 0 was no soil removal and 10 was complete soil removal. NatSurf 265 shows a 30% improvement in soap scum removal compared to a standard AEO in a bathroom cleaner (Figure 1).

Figure 1: Results of a panel test assessing the cleaning performance of a bathroom cleaner with NatSurf 265 or C9-11 5EO

Kitchen Greasy Soil Test

The main cleaning challenge in the kitchen is to remove greasy food and cooking soils from hobs and countertops. In order to assess cleaning performance, a greasy soil consisting of vegetable and animal fats was applied evenly to ceramic tiles (Image 2).

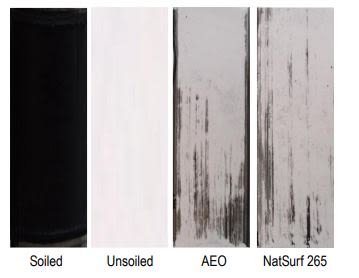

Image 2: Photographs of ceramic tiles with kitchen greasy soil applied, before and after cleaning with two all-purpose cleaners

The Sheen Wet Abrasion Scrub Tester was used again to assess the performance of NatSurf 265 comparing two all-purpose cleaner formulations, one containing a standard C9-11 5EO alcohol ethoxylate surfactant (AEO) and the other containing an equivalent amount of NatSurf 265 (see Formulation section, HC/HS/80). To evaluate the efficacy of the two formulations, the panelists were asked to rate the tiles on a 0-10 scale, where 0 was no soil removal and 10 was complete soil removal.

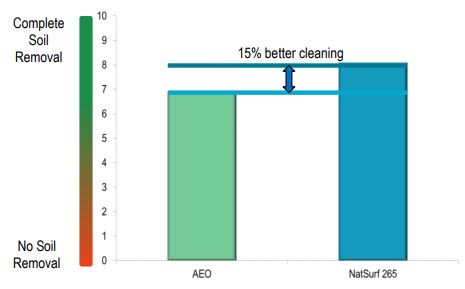

The NatSurf 265-based all-purpose cleaner gave 15% better cleaning than the conventional AEO.

Figure 2: Results of a panel test assessing the cleaning performance of an all-purpose cleaner with NatSurf 265 or C9-11 5EO

Industrial Greasy Soil Test

In order to assess the performance of NatSurf 265 in a more industrial soil, a mixture of fats, mineral oil, clay and particulates was applied to vinyl tiles (Image 3).

Image 3: Soiled tile (left) before cleaning and an unsoiled tile (right)

The tiles were cleaned with 1.25% surfactant solutions using a scrub tester. NatSurf 265 performance (HLB 13.6) was compared to nonylphenol ethoxylate NP-9 (HLB 12.9).

After cleaning, each tile was examined using a spectophotometer to measure the percentage soil removal (% SR). NatSurf 265 gave 15% better cleaning, showing 90% SR compared to 78% SR from the NP-9 solution (Image 4).

Image 4: Tiles cleaned with 1.25% NP-9 (left, 78% clean) and 1.25% NatSurf 265 (right, 90% clean)

Hand Dishwash Soil Test

To test the cleaning performance of NatSurf 265 in a hand dishwashing (HDW) detergent, ceramic dining bowls were stained with an equal amount of dyed soil, which consisted of a mixture of different food-stuffs in oil. The formulations tested were HC/DW/13 (see Formulations section), where SLS had been partially replaced with 6.00% NatSurf 265, and the equivalent formulation with SLS at 11.51% (no NatSurf 265). The bowls were cleaned with 0.1% solutions of the HDW formulations, using an overhead stirrer at a set speed to agitate the water at 40°C.

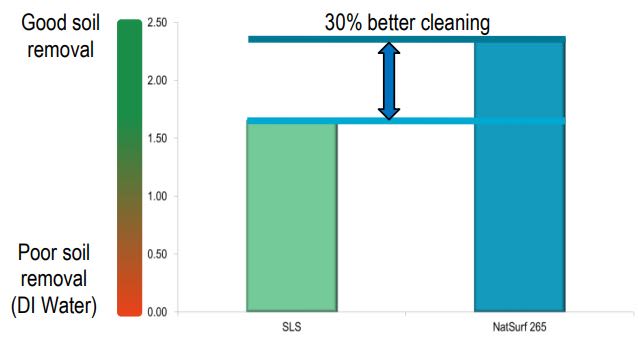

Once dry, the bowls were panel tested to rate soil removal, scoring the bowls between 0 and 5, where 0 was a bowl cleaned with DI water alone. 87% of panelists rated the bowls washed with the NatSurf 265 formulation as cleaner than the bowls cleaned with the SLS formulation, with ratings showing 30% improved cleaning on average compared to SLS alone.

Figure 3: Hand dishwashing cleaning performance panel test data for two formulations: one where SLS (5.50%) had been partially replaced with NatSurf 265 (6.00%) and one with SLS (11.51%)

Figure 3: Hand dishwashing cleaning performance panel test data for two formulations: one where SLS (5.50%) had been partially replaced with NatSurf 265 (6.00%) and one with SLS (11.51%)Formulation Benefits in Hard Surface Cleaners

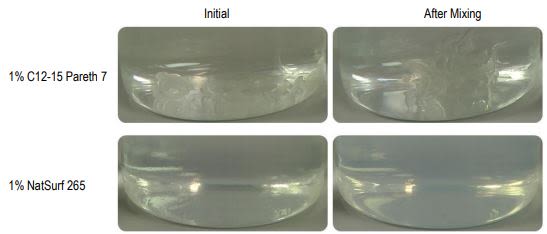

NatSurf 265 shows excellent cold water solubility and does not go through a gel phase in aqueous solution, unlike some conventional alcohol ethoxylate surfactants. This makes it easier to handle and formulate with across a broad range of processing conditions (Table 1).

Table 1: A 1% solution of NatSurf 265 (below) dissolved within seconds, unlike a 1% solution of C12-15 7EO, which formed a stable gel, even after several minutes of mixing (above).

Excellent Formulation Stability

With excellent pH tolerance in alkaline and acidic formulations, NatSurf 265 can be used to formulate products over a broad pH range, suiting numerous different applications (Table 2).

3% Natsurf 265 is stable in KOH up to 9.0% 6% NatSurf 265 is stable in 20% HCl Table 2: pH compatibility data for NatSurf 265

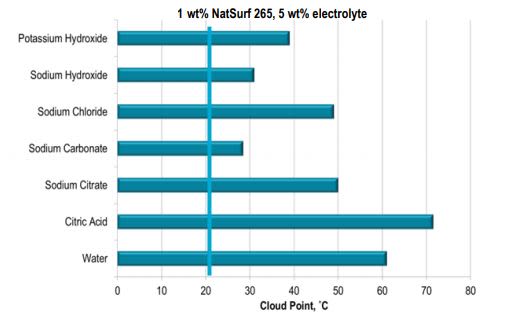

NatSurf 265 has demonstrated compatibility with hydrogen peroxide and also shows excellent tolerance of a range of electrolytes, allowing clear and stable solutions at room temperature (Figure 4).

Figure 4: Effect of electrolyte (5 wt%) on cloud point of NatSurf 265 (1 wt%) in water

Fragrance and Oil Solubilisation

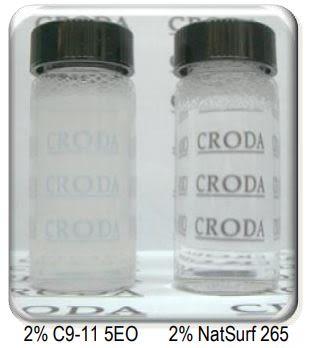

NatSurf 265 improves fragrance and oil solubilisation within a formulation, meaning that additional fragrance solubilisers can be reduced or even eliminated. Image 5 shows comparable solutions of 2% surfactant with 0.2% fragrance; NatSurf 265 gives a completely clear solution, whereas the AEO is cloudy and would require the addition of a separate solubiliser.

Image 5: Hazy solution of 2% C9-11 5EO and 0.2% fragrance (left) compared to a clear solution of 2% NatSurf 265 and 0.2% fragrance (right)

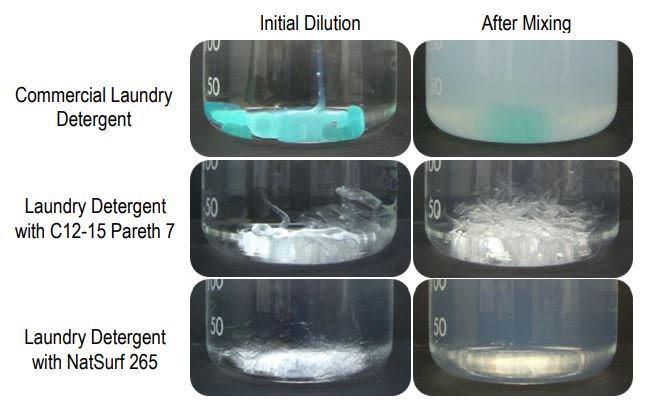

Laundry Detergents Test

NatSurf 265 can be used to create highly concentrated laundry detergents, where there is very little water and very high surfactant loadings. Formulations with NatSurf 265 also retain their clarity and low viscosity.

In one formulation example (see Formulation section, HC/LF/26) NatSurf 265 was pushed to its maximum inclusion level to give a clear, free-flowing, homogeneous formulation. The highest level possible was 55.00%. For comparison, the same approach using C12-15 7EO led to a hazy product with high viscosity and inconsistent structure at just 20% inclusion. This is a difference of 35%, or over 2.5 times more NatSurf 265. The difference in clarity can be seen in Image 6.

Image 6: Photograph of an ultra-concentrated formulation with 55% NatSurf 265 (right, HC/LF/26) compared to a formulation with C12-15 Pareth-7 (left)

Reduced Viscosity Build

In contrast to some conventional alcohol ethoxylates, formulations with NatSurf 265 remain thin and freeflowing (Table 3). This reduced viscosity build adds to the favorable handling characteristics of NatSurf 265, meaning that processing is easy and viscosity can be controlled as desired at the end of production.

Brookfield viscometer (25°C, S21, 50 rpm)

20% AEO 693 cps 55% NatSurf 265 80 cps Table 3: Brookfield viscosity data for a 55% NatSurf 265 formulation (HC/LF/26) and the equivalent formulation with 20% C12-15 7EO

Fast Dissolution of Laundry Detergents

Ultra-concentrated formulations with NatSurf 265 dissolve quickly, even in cold water, so they can get to work faster (Table 4). Some concentrated detergents form stable gels when diluted in the wash, taking quite some time to disperse, an effect which is often worse at cold temperatures. Fast dissolution gives NatSurf an advantage in short, cold wash cycles where rapid cleaning is key.

Table 4: Dispersing performance of different laundry detergents in water at 15ºC

Table 4: Dispersing performance of different laundry detergents in water at 15ºCSuperior Cleaning Performance

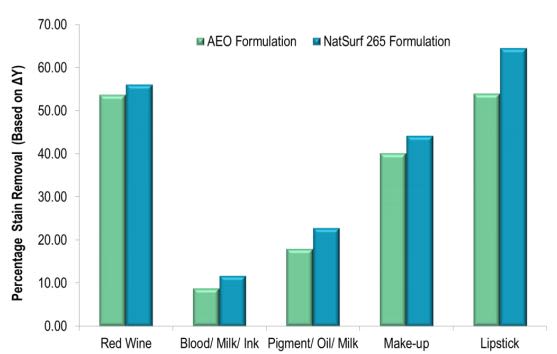

Pre-soiled cotton swatches from CFT were tested to demonstrate the superior performance which is achievable with NatSurf 265. Wash testing used 35 ml detergent and 3.5 kg clean white base load at 40°C in a Miele W1945 EcoComfort consumer washing machine, with automatic program control deactivated. Percentage stain removal was calculated using ΔY measurements, referenced to the completely clean white fabrics. NatSurf 265 shows enhanced stain removal across a wide range of stain types, with a selection shown in Figure 5.

Figure 5: Improved stain removal from standardized, pre-soiled cotton swatches at 40ºC when using a NatSurf 265 formulation compared to a conventional AEO formulation

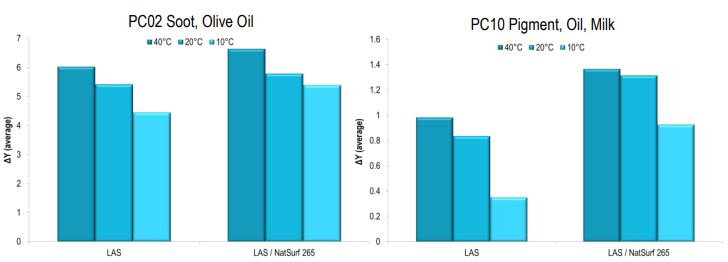

Figure 5: Improved stain removal from standardized, pre-soiled cotton swatches at 40ºC when using a NatSurf 265 formulation compared to a conventional AEO formulationSmaller scale testing used a Tergotometer to demonstrate NatSurf 265 performance as a co-surfactant. Sodium dodecyl benzene sulfonate (LAS) was compared to a 50/50 mix of LAS and NatSurf 265, with testing conducted at 1g/l, pH9. Figure 6 shows the improved ΔY values for NatSurf 265 as a co-surfactant on a selection of particulate stains at 40, 20 and 10°C after a 15 minute wash, showing that NatSurf 265 can be used to improve the cleaning performance of laundry detergents.

Figure 6: Improved cleaning performance at different temperatures when using NatSurf 265 as cosurfactant with LAS, compared to LAS alone

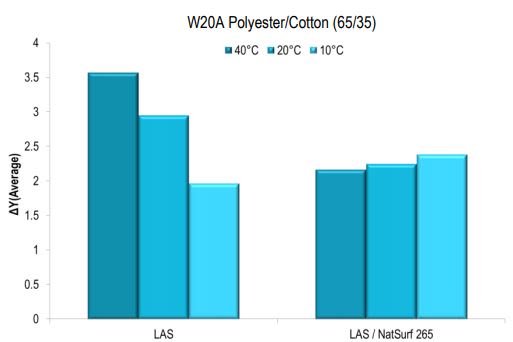

Figure 6: Improved cleaning performance at different temperatures when using NatSurf 265 as cosurfactant with LAS, compared to LAS aloneMonitoring the maintenance of white fabrics in detergency tests with NatSurf 265 shows that the product also gives reduced redeposition. For example, overall change in whiteness (graying) was measured on polycotton W20A from wfk (65% polyester, 35% cotton) in the Tergotometer test above (Figure 7). NatSurf 265 provides a consistently high level of cleaning performance across all wash temperatures.

Figure 7: Reduced graying of white fabrics when using NatSurf 265 as co-surfactant with LAS, compared to LAS alone

Foaming Performance

Foam heights were measured using the Ross Miles Foam test method. Each surfactant was measured as a 0.1% w/w solution in water at 25˚C and the foam height over a period of 10 minutes were measured. The data for NatSurf 265 (Figure 8) shows medium foam properties at different pH values.

Figure 8: Ross Miles foaming performance of NatSurf 265 at different pH values for a period of 10 minutes

Figure 8: Ross Miles foaming performance of NatSurf 265 at different pH values for a period of 10 minutesCMC Determination

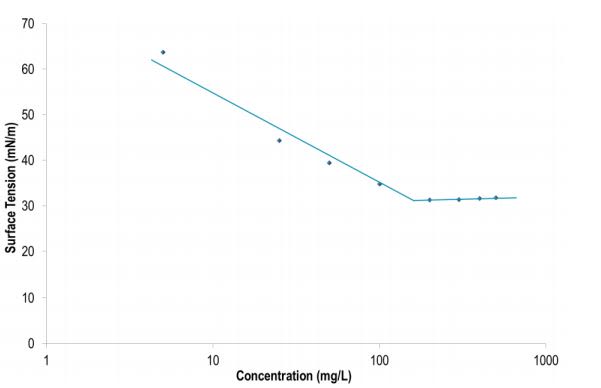

Critical Micelle Concentration (CMC) values are important indicators when considering which surfactant will provide optimal performance benefits for your formulation. The lower the CMC then the less surfactant is required to effectively emulsify, solubilise and disperse soils. The CMC value that can be seen in Figure 10 below indicates the amount of surfactant required to reach maximum surface tension reduction. The value of the CMC depends on the temperature, pressure and on the presence and concentration of other surface active substances and electrolytes. The value of CMC for NatSurf 265 at atmospheric pressure is 200 mg/L @ 25°C (Figure 10).

Figure 10: Surface tension versus concentration for NatSurf 265 at 25°C

Figure 10: Surface tension versus concentration for NatSurf 265 at 25°C

Applications & Uses

- Markets

- Applications

- Home Care Applications

- I&I Cleaning Applications

- Applications

- Hard surface cleaning

- Liquid laundry concentrates

- Laundry monodose formats

- I&I concentrates

- Hand dishwashing detergent

- Applications

- Surface Care

- Fabric Care

- Dishwash

- Vehicle Care

Properties

- Physical Form

- Odor

- Characteristic

- Appearance

- Clear liquid

- Soluble in

- Water

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Cloud Point (at 1%) | 60.9 | °C | — |

| pH (at 1%) | 5 | — | — |

| Wetting (1500 ppm) | 38 | sec. | — |

| Surface Tension (at 1000ppm) | 35 | mN/m | — |

Regulatory & Compliance

- Certifications & Compliance

Packaging & Availability

- Country Availability

- Regional Availability