Knowde Enhanced TDS

Identification & Functionality

- Carrier

- Chemical Family

- CASE Ingredients Functions

- Technologies

Features & Benefits

Applications & Uses

- Markets

- Applications

- Cure Method

Properties

- Appearance

- Clear Liquid

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Average Molecular Weight | 1750 - 1950 | — | — |

| Functional Group | Silane | — | — |

| Kinematic Viscosity (20°C) | 173 | cSt | — |

| Refractive Index at 20°C | 1.349 | — | — |

| Specific Gravity at 20°C | 1.51 | g/ml | — |

Regulatory & Compliance

- Certifications & Compliance

Technical Details & Test Data

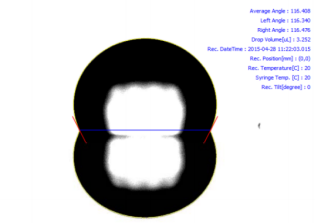

- FluoroSyl Coated Glass and Water Contact Angle

Contact Angle(Average)[degree] 116.40768 Left Angle[degree] 116.33956 Right Angle[degree] 116.47581 Height from Top to Base[mm] 1.35872 Base Line Length [mm] 1.84448 Base Area[mm^2] 2.67201 Drop Volume[ul] 3.25209 Wetting Energy[mN/m] -32.37818 Spreading Coefficient[mN/m] -105.17818 Work of Adhesion[mN/m] 40.42182 Rec. Date 2015-04-28 Rec. Timee 22:03.0 - Case Study of FluoroSyl Coated Polycarbonate and Mineral Oil

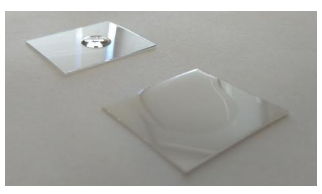

Two pieces of polycarbonate were plasma treated to clean and hydroxylate the surfaces. The cleaned polycarbonate was dip coated with FluoroSyl and air cured at room temperature for 60 minutes. The picture shows 100 microliters of mineral oil on each of the pieces. The FluoroSyl coated piece is “repelling” oil, and the uncoated piece is “attracting’ oil.

- Case Study of FluoroSyl Coated Glass and Spray Paint

A piece of glass was divided into two and the #2 side was cleaned with a mix of 30% Cerium Oxide in water. FluoroSyl at 0.2% in IPA was spritzed-on and evenly spread using a squeegee and allowed to cure overnight and then spray painted black. The #2 side is spray paint/graffiti, sharpie, water, and oil repellent. The #1 side is not paint, water and oil repellent.