Knowde Enhanced TDS

Identification & Functionality

- Fluids & Lubricants Functions

- Technologies

Features & Benefits

Applications & Uses

- Markets

- Fluids & Lubricants Type

- Fluids & Lubricants End Use

- Use Level

- 1.5 - 5 % by weight

- Applications

- EP/AW/AF

- Antioxidation additive package for greases, industrial lubricants

Properties

- Physical Form

- Appearance

- Yellow semi liquid (at 25°C)

- Insoluble in

- Water

- Physico-Chemical Properties

| Value | Units | Test Method / Conditions | |

| Specific Density (at 25°C) | 1.26 | g/cc | — |

| Fire Point | 175.0 | °C | ASTM D92 |

| Fire Point | 160.0 | °C | ASTM D92 |

Technical Details & Test Data

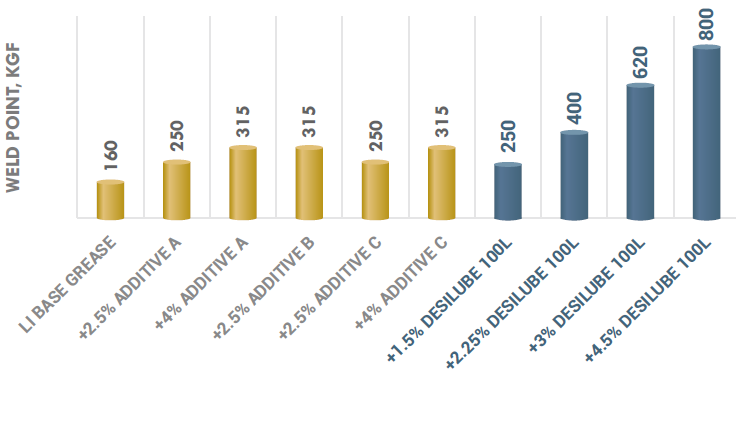

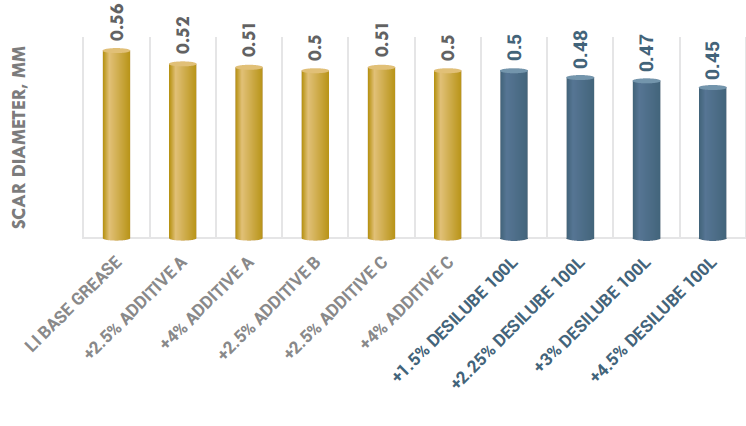

- Desilube 100L Mass Percent Performance Summary

Mass Percent Desilube 100L 1.5 2.25 3 4.5 Li/LiX greases, NLGI2 98.5 97.75 97 95.5 Results EP, weld kgf

ASTM D2596250 400 620 800 Wear, mm

ASTM D22660.5 0.48 0.47 0.45 Copper corrosion, ASTM D4048 1b Rust ASTM D1743 (distilled water) pass * Additive response depends on many factors. Therefore, results reported are only an indication of performance and cannot be considered a guaranteed level of performance.

- Desilube 100L Performance Comparison

Four ball EP and four ball wear comparison: Desilube 100L vs other performance additives on the market

Four Ball EP, ASTM D2596

Four Ball Wear, ASTM D2266

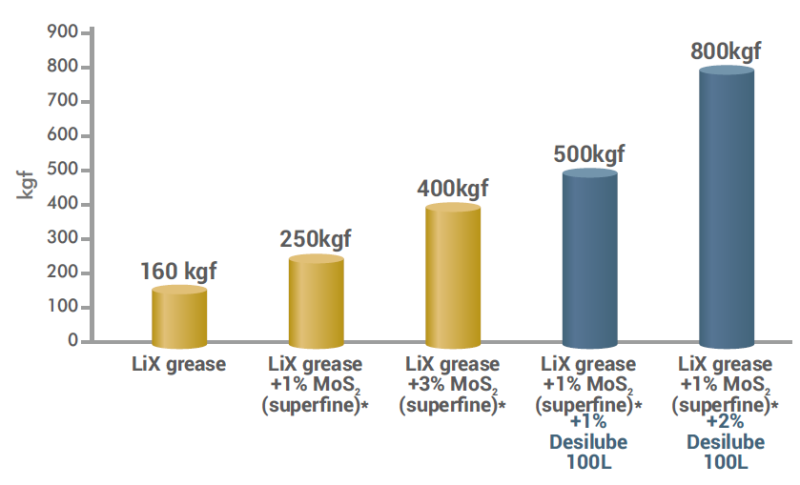

Desilube 100L as extender/booster for MoS2

- * Please note that different grades of MoS2 may give you variation of weld load plus/minus 1 stage

- Additive response depends on many factors. Therefore, results reported here are only an indication of performance and can not be considered a guaranteed level of performance.

Packaging & Availability

- Packaging Information

- 55 gal drum: 250kg/551lb

- 5 gal pail: 25kg/55lb