Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Polymer Name

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- Materials Features

- Tedlar® PVF Features in Aerospace Applications

DuPont™ Tedlar® protective film offers attractive, easy-to-clean, scuff-resistant surface protection to aircraft interiors. Tedlar® films are lightweight, have excellent conformability and offer superior resistance to harsh cleaners, chemicals and solvents, eliminating the need for repainting and reducing maintenance costs to help provide every passenger a fresh look on every flight.

The proven performance of Tedlar® film has made it the aircraft standard to which other materials used in the industry are measured. Tedlar® film meets or exceeds Federal Aviation Administration (FAA) and European Union Aviation Safety Agency (EASA) standards.

Design flexibility

Tedlar® film gives airlines maximum interior design flexibility to create passenger areas that are attractive and easy to clean. Tedlar® films can be embossed and printed, enabling the use of many unique texture designs and can be tailored to various gloss levels, thicknesses and finishes.

Fade resistant

Tedlar® film is available in an array of fade-resistant colors to match the look of your aircraft. If necessary, the colors can be matched long after the initial installation. Transparent Tedlar® film is also available as an excellent overlaminate for printed patterns.

Applications & Uses

- Markets

- Plastics & Elastomers End Uses

- Tedlar® PVF for Aerospace Applications

- Interior ceiling and sidewall decorative panels

- Window shades

- Stow bins

- Lavatories and galleys

- Ceiling panels

- Personal service units (PSUs)

- Bulkhead partitions

- Insulation barriers

- Moisture barriers

- Cargo bin liners

- Aircraft wire markers

- Composite noise panels

- Partitions

- Monuments

- Closets

- Landing Gear Bay

- Cargo Protection

- Labeling

- Composite Release

- Composite Protection

- Current Use Case: Tedlar® in Commercial Passenger Aircraft

- Tedlar® has protected the interiors of aircraft since 1964 and continues to be the industryrecognized standard today.

- Tedlar® was chosen in commercial aircraft due to its high standard of non-flammability. It is certified by FAA and EASA with excellent fire resistance.

- Tedlar® continues to be used because of its durability. The interior of aircraft see thousands of customers over years and are able to stay looking clean year in year out.

Properties

- Chemical Resistance

- Color

- Flame Rating

- Physical Form

- Physical Properties

- Thermal Properties

| Value | Units | Test Method / Conditions | |

| Coefficient of Friction (Film on Metal) | 0.18 - 0.21 | — | ASTM D1894 |

| Falling Sand Erosion (on PET Backing) | 04-Aug | L/µm | ASTM D968 |

| Falling Sand Erosion (on PET Backing) | 4-8 | L/µm | ASTM D968 |

| Impact Strength | 45 - 89 | J/mm | ASTM D3420 |

| Moisture Absorption (for most types) | max. 0.5 | % | Water Immersion |

| Optical Transmission of Clear Films | 93 | % | ASTM D1003 |

| Refractive Index of Clear Films | 1.46 | — | ASTM D542 |

| Shore Hardness | D60 - D70 | — | ASTM D2240 |

| Strain at Break | 90 - 250 | % | ASTM D882 |

| Tear Strength (Initial) | 100 - 200 | N/mm | ASTM D1004 |

| Tear Strength (Propagated) | 5.9 - 24 | N/mm | ASTM D1922 |

| Tensile Modulus | 2.1 - 2.6 | GPa | ASTM D882 |

| Ultimate Strength | 55 - 110 | MPa | ASTM D882 |

| Yield Strength | 34 - 41 | MPa | ASTM D882 |

| Value | Units | Test Method / Conditions | |

| Coefficient of Thermal Expansion | 5 - 10 x 10^-5 | m/m·K | ASTM D696 |

| Lower Glass Transition Temperature | 15 to -20 | °C | Various |

| Peak Melting Temperature | 190 - 210 | °C | ASTM E1269 |

| Relative Thermal Index - Electrical Strength | 140 | °C | UL 746B |

| Relative Thermal Index - Mechanical Impact | 120 | °C | UL 746B |

| Relative Thermal Index - Mechanical Strength | 125 | °C | UL 746B |

| Specific Heat Capacity | 1.0 - 1.1 | kJ/kg*K | ASTM E1269 |

| Temperature Range (continuous use) | -70 to 105 | °C | — |

| Upper Glass Transition Temperature | 40 - 50 | °C | Various |

Regulatory & Compliance

Technical Details & Test Data

- Resistance to Bacteria

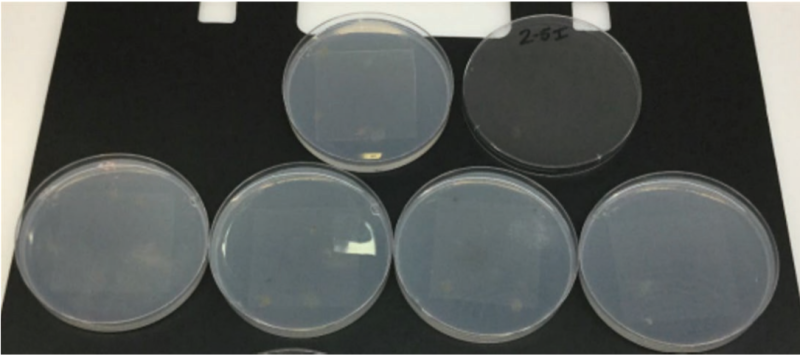

Bacterial growth is also not supported by Tedlar® PVF films which are formulated without plasticizers, processing aids or other additives that can become a nutrient source for microbes. This was demonstrated using ISO 846:2019 Method C: Evaluation of the Action of Microorganisms – Resistance to Bacteria. Several Tedlar® PVF films were tested, along with DuPont™ Tedlar™ Wallcovering. They are listed in Table 4.

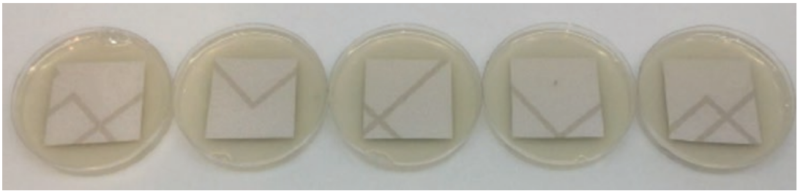

Samples were placed on agar that was previously inoculated with Pseudomonas aeruginosa at the desired concentration and covered with additional inoculated agar. Negative control samples were also prepared with non-inoculated agar to facilitate comparison to inoculated samples. The samples and control were incubated for 28 days at 28-30 ˚C and evaluated for visible evidence of growth. The results for all the Tedlar® PVF films and DuPont™ Tedlar™ Wallcovering showed the same result; there was no growth on or around all five replicate samples and therefore the specimens do not contain nutritive components for this bacterium. This is illustrated in Figures 4 and 5 for the transparent Tedlar® PVF film and the wallcovering.

Tedlar® PVF Film or Product Typical End Use TWH10SS3

1 mil white Tedlar® filmBuilding & Construction Inoculated specimens at Day 28

No bacterial growth in the agar or around the specimens. The specimen does not contain nutritive components.

Figure 4: Transparent Tedlar® (TTR10BM3) after 28 days of incubation in ISO 846 Method C, showing no bacterial growth in the agar or around the specimens.

Inoculated specimens at Day 28

No bacterial growth in the agar or around the specimens. The specimen does not contain nutritive components.

Figure 5: DuPont™ Tedlar™ Wallcovering after 28 days of incubation in ISO 846 Method C, showing no bacterial growth in the agar or around the specimens.