Knowde Enhanced TDS

Identification & Functionality

- Polymer Name

- Technologies

Features & Benefits

- Materials Features

- Advantages of Elastron V

- Service temperature -40˚C to 140˚C

- Wide hardness range (30 ShA- 65 ShD)

- Lower density (Density changes between 0,89 and 1,05 g/cm³)

- Design flexibility

- Good resistance to acids and bases as well as oils (ex: IRM 903 , IRM 901)

- UV and ozone resistance

- Recyclable

- Easy processing with shorter cycle time

- Provides quite higher saving on the processing cost (less scrap)

- Low flex fatigue

- Flame retardant grades available

- Low compression set

- Weathering resistance

- ELASTRON Products Features at a Glance

• Excellent UV and ozone resistance

• Abrasion resistance

• Available products for adhesion to PP,PE, etc and engineering plastics. (ABS,PC,PA, etc.)

• High temperature resistance

• OEM approved grades

• Excellent compression set

• Low temperature resistance

• %100 recyclable- Key Benefits of Weatherseals

- Long term durability

- Excellent Weathering Resistance

- Excellent Sealing Performance

- Elasticity

- Low Weight

- Fast Production, Reduced Lobor Cost

- Process Advantages

- Recyclable

- Features For Electrical & Cables

• Excellent surface appearance

• Resistance to high temperatures

• UL 94 HB / V0 / V1 listed products

• Halogen Free Flame Retardant

(HFFR)

• 100% recyclable

• Copper stabilized grades

• Low dielectric constant and high oxygen index

• High dielectric strength, surface and volume resistivity

• Ease of extrusion

• Excellent low temperature properties

• Excellent compression set properties

• Low smoke density

• RoHS, ELV and WEEE compliance

• Non-toxic

• Resistant to oil, chemicals, acids&bases

• Easy to color with masterbatch

• Excellent UV resistance

• Colored compounds available- Key Benefits of Under the Hood & Chasis

• Long term durability

• Eliminates the clamp need with system component welding

• Excellent fluid resistance

• Reduced leakage risk

• Low weight

• Fast production, reduced labor cost

• Process advantages

• Vibration dampering

• Elasticity

• Recyclable- Key Benefits of Exterior

• Long term UV and ozone resistance

• Colorable

• Tear and abrasion resistance

• Impact resistance at low and high temperatures

• Low weight

• Flexible at low temperatures Easy processing and good flow property

• Bondability to various plastics (PP, ABS, PA, PC, PE)

• Low labor cost

• Recyclable- Features For White Goods & Appliances

• Resistant to detergents, acids, bases, etc.

• Good weathering resistance

• Excellent UV resistance

• Colored compounds

• Excellent compression set

• Resistant to high temperatures

• Excellent low temperature resistance

• Co-extrusion with many plastics

• Excellent surface appearance

• 100% recyclable- Key Benefits of Interior

• UV Resistance

• Colorable

• Soft Touch, antislip

• Scratch and abrasion resistance

• Low emission

• Low weight

• Low odor behavior

• Easy process and good flow property

• Recyclable- Features of Medical

Features

• Excellent bonding to many thermoplastics

• Easy to color

• Excellent surface appearance

• Antistatic compounds available

• Soſt touch compounds

• Availability of transparent grades

• 100% recyclable

Other Features

Elastron medical TPE compounds are tested according to USP ‘88’ for their in vivo biocompatibility and ISO 10993-5, USP ‘87’ for their in vitro cytotoxicity. Tested compounds all have USP Class VI approvals. Elastron medical TPE compounds also meet requirements of European Pharmacopeia monographs 3.2.8 sterile single-use plastic syringes and 3.2.9 rubber closures for containers for aqueous parenteral preparations for powders and for freeze-dried powders. Elastron medical TPE compounds are sterilizable with gamma irradiation, ethylene oxide (EtO) and steam.- Features of Food

The monomers and additives used in manufacturing food contact TPE grades should be listed in the Union List of Authorized Substances of Regulation 10/2011/EC on plastic materials and articles intended to come into contact with food. Ingredients used in manufacturing these products are subject to a specific migration limit (SML).

Elastron provides the quality and conditions of above mentioned regulation and limits.

• Excellent bonding to many thermoplastics

• Easy to color

• Excellent surface appearance

• Soſt touch compounds

• Availability of transparent grades

• 100% recyclable

• NSF 51/61 Compliant Grades

Applications & Uses

- Applications

- Compatible Polymers & Resins

- Plastics & Elastomers Processing Methods

- Processing Information

Injection Molding Typical Value (English) Typical Value (SI) Rear 311 to 347 °F 155 to 175 °C Center 329 to 365 °F 165 to 185 °C Front 338 to 374 °F 170 to 190 °C Nozzle 356 to 410 °F 180 to 210 °C Mold 77 to 122 °F 25 to 50 °C Recommended Predrying 2 hours at 194 °F 2 hours at 90°C Extrusion Molding Typical Value (English) Typical Value (SI) Feed 311 to 329 °F 155 to 165 °C Rear 320 to 356 °F 160 to 180 °C Center 329 to 365 °F 165 to 185 °C Front Head 356 to 410 °F 180 to 210 °C Die 365 to 419 °F 185 to 215 °C Recommended Predrying 2 hours at 194 °F 2 hours at 90°C - Automotive Applications

Elastron develops not only products but also solutions for special applications according to automotive industry needs.

As a result of this focus Elastron is certified with IATF 16949. With its specialized grades Elastron offers solutions for weatherseal, interior, exterior, under the hood applications. We are in close cooperation with OEMs to track down the needs closest way to serve our partners. The grade selection is not limited. As we are eager to serve our customers as a solution provider, thus we are flexible to develop tailor made products for our partners. Not limited with this list but main applications you can face at an automobile are;

Weatherseals

• Inner&Outer Belt Line Seals

• Glass Run Channels

• Sun Roof Seals

• Glass Encapsulation

• Corner Molding

• Slip Coat

• End Caps

• Cowl Vent Seal

Exterior

• Bumper Spoiler

• Wiper Spoiler

• Mud Flaps

• Antenna Bezels

• Wheel Housing Parts

• Fuel Entrance Cover Seal

• Side & Front Spoiler

Interior

• Pad Heel

• Pads & Cup Holders

• Hvac Door Seals

• Floor Mats

• Seat Gaskets

• Glovebox Cover & Housings

• Pedal

• Horn Cover

• Handbreak Mechanism Seal

• Handbreak & Gearshift Bellow

Under the Hood & Chassis

• Clean Air Duct

• Suspension Bellows

• Radiator Seals

• Steering Bellows & Dust Boots

• Grommets & Plugs

• Fuel Line Hose

• Mechanism Cable Covers & Brake Conduit

• AC Waste Ater Pipe

• Air Filter Seal

Glowbox Cover & Housing

Glowbox covers made with colourable Elastron TPO meets low emission standards required for interior parts and provides good impact long term UV and abrasion resistance.

Gearshift & Handbrake Bellow

Gearshift and Handbrake Bellows made with Elastron TPV and Elastron Goffer long time UV durability, good flow and surface properties.

Pad Heel

Pad heel made with Elastron TPO is bondable to polyester mat with special hot melt and provides antislip effect for driver comfort.

Pad & Cup Holder

Pads and cup holders made with Elastron SEBS and Elastron TPV provides light weight, perfect appearance and meets low emission requirements for automotive interior applications.

Handbrake Mechanism Seal

Various gaskets made with Elastron TPV and Elastron SEBS based products offer improved isolation high surface quality and meets low emission standards.

Horn Cover

Elastron TPO and Elastron G (SEBS based) products offer high scratch and abrasion resistance. Elastron products bondable to ABS and PP with 2K molding reduce cycle time and cost.

HVAC Door Seal

Elastron TPV provides long term dimensional stability and sealing advantage in flapper door seals. It meets the low emission standards.

Mat

Mats made with Elastron SEBS compounds provides fast production lower weight long term abrasion and UV resistance compared to Rubber

Pedal

Pedals made with Elastron TPV provides long term abrasion resistance and meet low emission standards required for interior parts.

Wiper Spoiler

Long term UV stability, scratch resistance and non staining properties make Elastron TPV a choice for Wiper Spoiler application.

Side & Front Spoiler

Spoilers made with Elastron TPV and SEBS are flexible and have resistance to impact at low and high temperatures.

Antenna Bezel

Antenna bezels made from Elastron TPV prevents transmitting vibrations to metal surfaces and has long term dimensional and UV stability.

Fuel Entrance Cover Seal

Elastron TPV is used at fuel entrance cover with the advantages of splash resistance to gasoline and long term sealing performance.

Mud Flap

Mud flaps made with Elastron TPO and Elastron SEBS remains flexible at low temperatures and have excellent UV stability

Wheel Housing Part

Injection molded Elastron TPV and Elastron TPO remain flexible at low temperatures and dampen the noise and vibration.

Air Filter Seal

Elastron TPV bondable to PP provides high heat and chemical resistance, long term sealing and fast processing for air filter seals.

Clean Air Duct

3D Blow Molding technology is used to bring together PP and Elastron TPV or Elastron TPO to reduce weight and to provide design option for different part geometry. Mechanism Cable Cover & Brake Conduit

Mechanism Cable Cover and Brake

Conduit made from Elastron TPV and Elastron TPO provides impact resistance, flexibility, corrosion resistance and superior dampening properties for cable cover application.

AC Waste Water Pipe

Elastron TPV bondable to PP prevents leakage and reduce the labor cost with 2K injection molding process in tubing applications.

Suspension Bellow

Suspension Bellows can be produced with Extrusion Blow Molding. Bellows produced with Elastron TPV reduces cycle time and labor cost.

Radiator Seal

Elastron TPV coextruded with PP dampens the noise around the radiator and provides long term heat and chemical resistance.

Steering Bellows & Dust Boot

Bellows made with Elastron TPV provides reduced cost, design flexibility with the process options; Injection Blow Molding Extrusion Blow Molding continious vacuum corrugation and Press Injection.

Grommet & Plug

Various plugs, bumpers and grommets can be produced with Elastron TPV and Elastron SEBS. Elastron products provides long term aging and heat resistivity.

Cowl Vent Seal

High flow SEBS based Elastron G Products be used for 2K injection process with PP.

Glass Run Channel

Good surface quality with excellent dimensional stability Elastron TPV provides lower cost and fast processing.

Sun Roof Seal

Especially designed Elastron TPV products for weatherseal applications reduce total vehicle weight and provide short cycle time comparing with EPDM rubber.

Inner & Outer Belt Line Seals

Elaston TPV Co-extruded with PP provides excellent sealing performance and weathering resistance.

Glass Encapsulation

Easy flow Elastron TPV and SEBS based products can be used in two different ways.

• Direct injection on glass

• Assembling to the glass after injection.- Electrical & Cables Applications

Elastron provides flexible and high performance TPE solutions for electric and cable applications.

Applications

• Wire & Cables

> Primary Insulation

> Cable Jacketing

> Welding Cables

> Coaxial Cables

> Mechanical Tool Cables

> Instrumentation Cables

• Cable Multigates And Grommets

• Industrial Plugs And Switches

• Electrical Seals And Other Accessories

Halogen Free Flame Retardant (HFFR) Compounds for Eelectrical

Applications

Elastron Halogen Free Flame Retardant (HFFR) grades also offer great advantages for electrical applications. TPE grades for both injection and extrusion processes are available.

• Excellent long term electrical

properties

• Halogen free

• Excellent bonding to many plastics

• UL V0, V1, V2 and HB listed

• RoHS, ELV and WEEE compliant

• Colored compounds available

• Non-toxic

• Copper stabilized grades

• Oil & chemical resistance

• Low smoke density

• Suitable for dry & wet applications

• Excellent UV and ozone resistance

• 100% recyclable

• Easy to color with masterbatch- White Goods & Appliances Applications

Elastron offers low and high temperature resistant, RoHS compliant, detergent, acid&base resistant grades with excellent compression set values.

• Washing Machine Applications

• Dishwasher Applications

• Dryer Applications

• Refrigerator Applications- Medical Applications

Elastron medical TPE compounds are tested according to USP ‘88’ for their in vivo biocompatibility and ISO 10993-5, USP ‘87’ for their in vitro cytotoxicity.

• Syringe tips

• Infusion bottle caps

• Clogs (Antistatic and steam

sterilizible for medical applications)

• Sterilizible for medical applications- Food Applications

With the help of the experiences gained from manufacturing of medical TPE compounds, Elastron offers high quality food contact TPE compounds.

• Food Packing

• Food Box Seals

• Grips for Kitchen Equipments

• Water Pump Seals

Properties

- Color

- Incompatible with

- PVC, Acetal

- Physical Properties

- Aging Test

| Value | Units | Test Method / Conditions | |

| Compression Set (at 100°C for 22 hr) | 35 | % | ASTM D 395 |

| Compression Set (at 23°C for 22 hr) | 18 | % | ASTM D 395 |

| Compression Set (at 70°C for 22 hr) | 29 | % | ASTM D 395 |

| Density | 0.91 | g/cm³ | ASTM D 792 |

| Durometer Hardness | 55 | Shore A | ASTM D 2240 |

| Elongation at Break | 500 | % | ASTM D 412 |

| Modulus of Elasticity (100%) | 1.6 | MPa | ASTM D 412 |

| Modulus of Elasticity (300%) | 2.7 | MPa | ASTM D 412 |

| Tear Resistance | 21 | N/mm | ASTM D 624 |

| Tensile Strength at Break | 4.5 | MPa | ASTM D 412 |

| Value | Units | Test Method / Conditions | |

| Ozone Resistance Stressed | No Cracks | — | — |

Regulatory & Compliance

- Certifications & Compliance

- Quality Standards

Technical Details & Test Data

- Additional Information

- ELASTRON products are not compatible with PVC and Acetal. Regrinding level up to 20% is recommended with minimum property loss.

- Processing information for Extrusion

Profile Extrusion

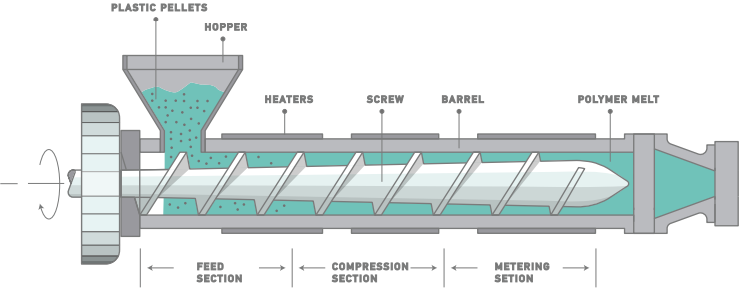

Typical thermoplastic Extruder

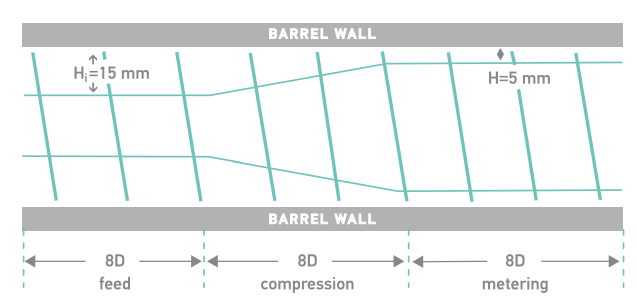

The selection of extruder barrel diameter depends on the dimension of the profile being produced. As throughput needing increases, diameter must be increased. A length to diameter ratio (L/D) of 24:1 are recommended. If higher capacity needed, L/D ratios of 30:1 preferred as they deliver a higher output capability, more uniform output rate and better melt quality with the proper screw design.

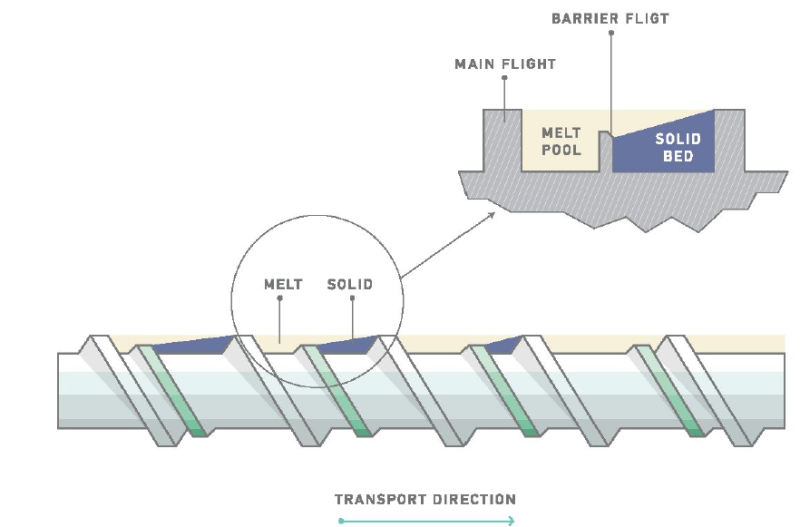

Extrusion of Elastron TPE product requires medium to high shear to properly plasticize (high shear for Elastron V products) and ensure properly processing at recommended temperatures. General purpose three zone screw design (feed, transition/compression, metering), having a compression ratio of 2.5 to 3.5 with an L/D of 18:1 to 24:1 is recommended. Barrier screws especially for Elastron V products are used successfully and are recommended.

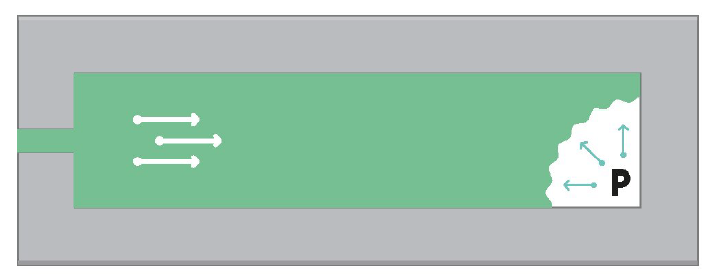

In order to be changed the melt flow from rotational to uniform laminar flow, there are some relaxation zone after the extruder barrel. During extrusion, melt being inside the barrel are compressed and stressed and it needs uniform flow before profiling.

Also breaker plate must be used for screening. Special screens must be installed on the breaker plate to catch the foreign or burned particles coming from the screw or barrel inside. Depending on the extruder size and capacity breaker plates having holes from 2mm to 4mm can be used, and 20 or 40 mesh screens are recommended.

The advantages of using screens:- Homogenize melting due to pressure,

- Catchting the burned particles coming from the screw,

- Catching the unmelted particles due to ununiform screw design,

- Increasing the shear,

- Increasing the surface quality,

- eIncreasing back pressure to better melt quality.

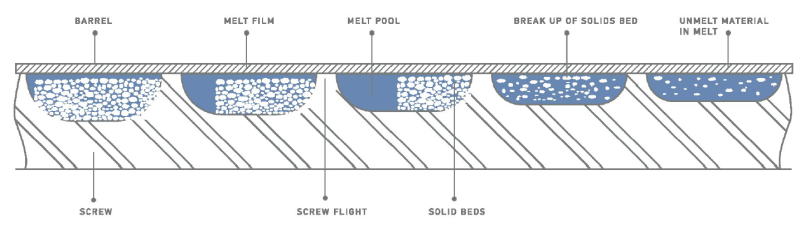

Melting in the Screw

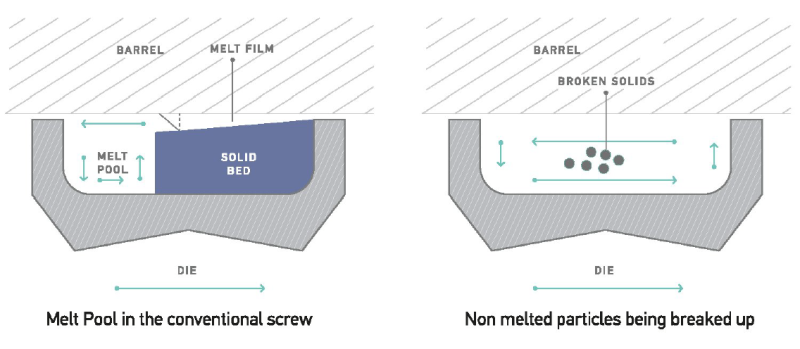

From left to right, during processing, melting takes places. The material being melted remains behind the solid material. That’s why if we don’t use enough compression ratio and the length of compression zone, there would be some unmelted material in the metering zone and we could see the rough surface on the profile. We have to ensure that the material coming to the metering zone have to be melted completely.

Melting in the Conventional Screw

How to Guarantee Melting (Barrier Screw)

Extra barrier flights let us extra compression during melt transition from filling to metering zone. This compression provides extra melting due to shear increasing.- Troubleshooting for Extrusion

1. Interrupted melt output: Unbalaced barrel temperatures.

- Reduce the feed zone temperature to feed the material to transition zone properly.

- Checked the temperature resistance and cooling sysytem.

- Checked the screen to catch the degraded, burned particles.

2. Surging: Due to contaminated material or wrong temeprature seetings unbalanced die exit.

- Increase the barrel temperatures gradually for each zone equally.

- Check the screen, clean if it is blocked.

- Check for the blockage in the hooper.

- Check the screw configuration.

- Clean the screw before production.

3. No Output: Die blocked due to solidification.

- Check the material enterence from hooper to barrel inside.

- There might be blockage in the hooper inside.

- Increase the die temperature to dissolve the blockage.

- Change the screen.

4. Rough Surface due to unmelted particles:

- Check the screen if there is any tears.

- Increase the temperatures especially in the compression zone.

- Check the zone temperature resistance.

- If there are any crosslinked particles on the surface, reduce the screw rpm and the zone temperatures in order to

- prevent the degradation.

5. Burned and discolored extrudate:

- Reduce the screw rpm.

- Reduce barrel temeperatures gradually until getting the right color.

- Select the extruder having lower L/D ratio for production.

6. Die lines:

- Select the material having lower viscosity.

- Increase the die temperatures.

7. Melt Fracture:

- Reduce the barrel temperatures.

- Change the material with in accordance with the die design.

8. Shark Skin:

- Reduce rpm.

- Change the screen.

- Increase the melt temperature.

9. Fish eyes:

- Check the material and screen for contamination.

- Material must be dried properly before using.

- Reduce the temperatures to prevent material degredation.

10. Bubbles on the profile surface:

- Be sure to dry the material properly.

- Reduce the melt temperature.

- Reduce screw rpm.

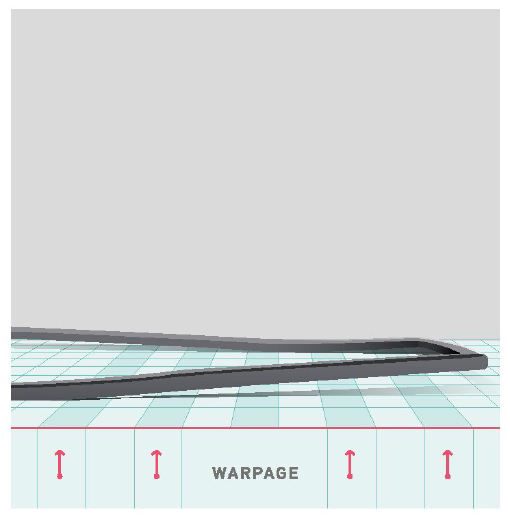

11. Warpage: Insufficient cooling

- Increase the cooling bath lenght, reduce the water temperature.

- Balance the die according the part wall thickness.

12. Orange Peel surface:

- Die temperaure is too low, increase the die temperature.

- Increase the temperature of the zones which is close to die.

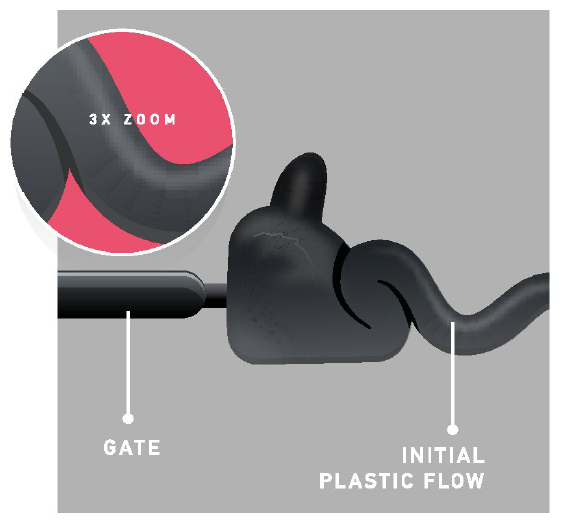

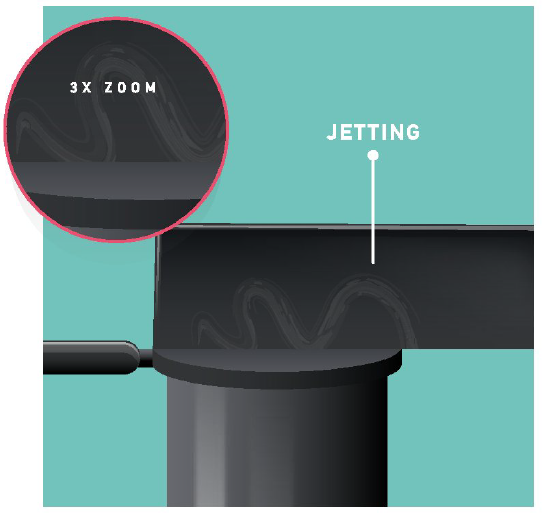

- Troubleshooting for Injection

1. Short Shot

- Restricted flow areas, such as wrong type of gates, wrong dimesion of runners, and thin walls.

- Low melt or mold temperatures.

- Due to insufficient ventillation, trapped air inside the cavity.

- Insufficient machine injection pressure, low injection speed.

- Machine mulfunctioning such as blocked feed throat, or a worn non-return valve that causes loss of injection pressure or there could be some pressure loss on the flowpath.

- Premature solidification of the material melt, poor injection speed profile, or prolonged injection time.

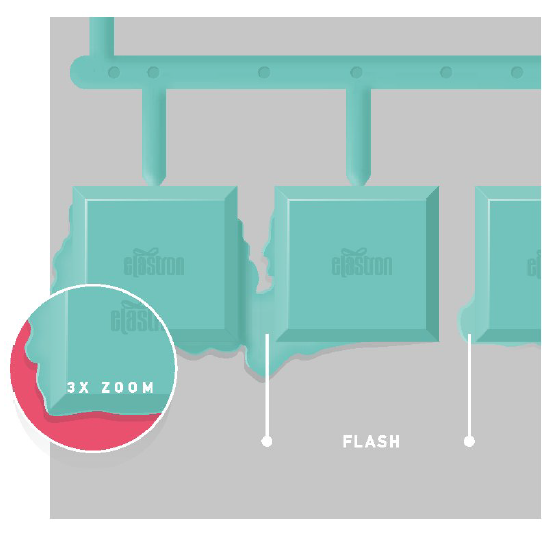

2. Flash

- Low clamp force: Clamping force must be higher than injeciton pressure. If the clamping force is too weak to hold the mold plates together during the injection process, flash takes place.

- Gap within the mold: Flash will occur if the parting surface does not contact completely, due to a deformed mold structure, parting surface defect, improper machine and mold set up, or flash or foreign material stuck on the parting surface.

- Injection parameters: High melt temperature (lowered the viscosity of the material) or high injection pressure win the calmping force and flash takes place.

- Nonconforming venting: Due to venting design and a very poor venting system, or venting dimension is not properly.

3. Sink Marks

- After injection, holding must be applied until gate completely freezing off, otherwise melt goes back to runner inside and sink marks takes place.

- Short cooling time, because after stress relaxation in cooling, new material loaded to the cavity replacing the voids.

- High melt temperature or mold temperature

- Due io mold design, there might be some pressure loss in order to hold the material after injection.

4. Splay Marks

If material are used without predrying, the moisture inside the material can cause this marks. Also high rpm during screw retraction, generates gas and this gas are injected the parts with melted material.

- Dryplastic according to our suggestion.

- Reduce injection speed, because high speed generates due to friction.

- Reduce melt temperatures by reducing the barrel temepratures.

- Reduce screw rpm, high rpm generates gas.

- Increase back pressure, increasing the back pressure discharge the gas through the hooper.

- Increase mold temperatures

- Increase venting

- Increase gate diameters, because tight diameter generates gas due to high shear rates.

5. Warpage

A differential cooling rate of the melt in two sections of the molded product.

- Reduce melt temperature to reduce the cooling time.

- Reduce the mold temperature to reasonable level according to our requirements

- Increase pack and hold pressures, if any pressure loss.

- Increase pack and hold times,

- Due to unsufficeient cooling time warpage takes place after ejection. That’s why increase the cooling time to cool the part to suffient level.

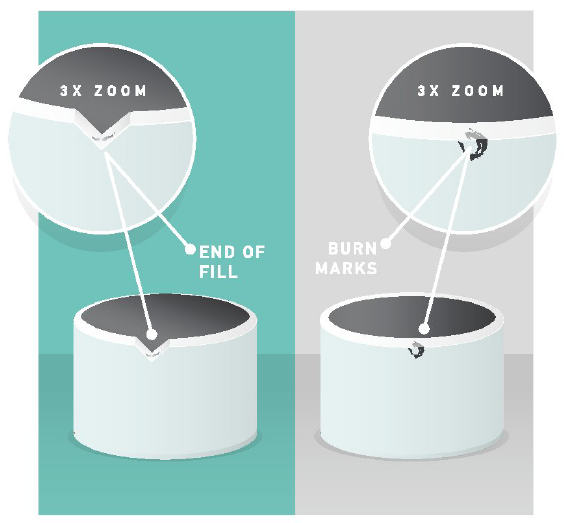

6. Burn Marks

Material degradation

Burn marks can result from the degraded materials and then appears on the surface of the molded part or near the venting areas. Material degradation is caused by:- High melt temperature: Excessive melt temperature can be caused by higher barrel temperature setting, or malfunctioning in the temperature controller.

- High screw rotation speed: If the screw rpm is too high during the plasticization time during screw retraction, that will create too much frictional heat, which could degrade the material.

- Restrictive flow path: When the melt flows through the flowpath which icludes restrictive nozzle, runner, gate, or part sections, shear rates gets incresedheat, which could degrade the material.

- High speed injection: Creates extra ternperatures due to frictional heat in the runner.

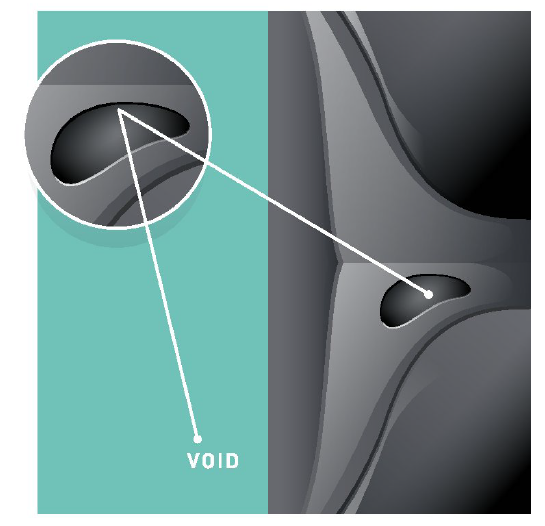

7. Voids

Occurs when the parts thickness is high. If the mold temperature is higher than normal during cooling, the plastic melt shrinks towards the wall and therefore sucks a vacuum void on the inside of the part

- Reduce melt temperature: Cooling after high temperature might cause the voids.

- Reduce mold temperature: High mold temperatures keeps the melt temperatures high, that’s why thiskind of voids occur.

- Reduce injection speed: High speed injection creates high frictional shear and melt cooling would be hard.

- Increase pack and hold pressures: Packing and holding pressures send the gas or airs to out through the ventilation channels.

- Increase pack and hold times

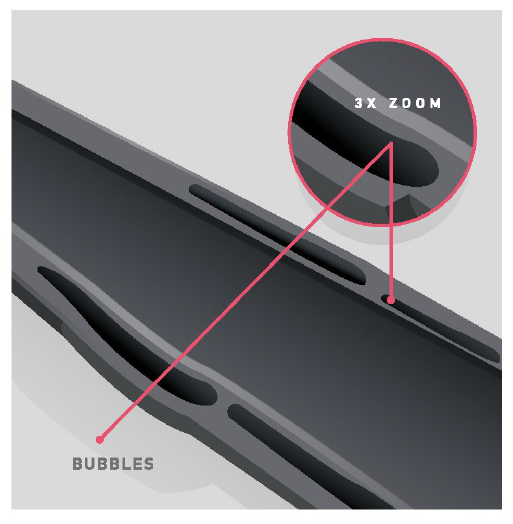

8. Bubbles

Moisture or gase coming from the product gets injected in the mold cavity this moisture or gas if embedded inside the melt can show up as bubbles.

- Dry material to suggested moisture levels:

- Increase back pressure: Back pressure let us send the gas to outside of the mold

- Reduce melt temperature

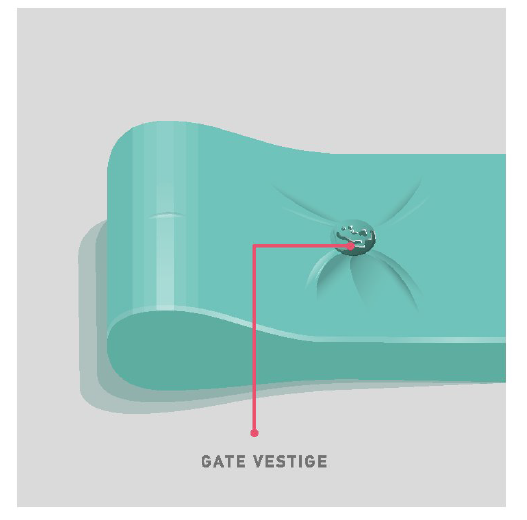

9. Gate Vestige

- When holding phase, reduce the injection speed and pressure

- Arrange the injection speed profile properly,

- Increase the melt temperature by using the barrel temperatures gradually

10. Jetting

- Place the gate to against to metal surface.

- Use an overlap gate or a submarine gate

- Slow down the melt with a gradually divergent flow area.

- Reduce injection speed

- Increase melt temperature

11. Weld Lines

- Increase melt temperature: If two different flow meets together as colder than normal, such king of traces would be coming out.

- Increase mold temperatures: Cold mold wall prevents the material flow.

- Increase injection speeds: Lower injection speed causes premature cooling.

- Increase venting: Ventilation supply us better flowing in the mold.