Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Polymer Name

- Technologies

- Product Families

Features & Benefits

- Materials Features

- KEY FEATURES

• ESD safe

• Best in class tear resistance

• Temperature resistance up to 120˚C

• Good abrasion and wear resistance

• Excellent chemical, solvent, oil and ozone resistance

Applications & Uses

- Markets

- Plastics & Elastomers End Uses

- APPLICATIONS INCLUDE

• ABS ESD replacement

• Electronics manufacturing ESD safe jigs and fixtures

• Snap fit connectors

• Heavy load vibration isolation

• Impact rated structural components

Properties

- Physical Form

- Material Specific Properties

| Value | Units | Test Method / Conditions | |

| Abrasion Loss | 20 | mm3 | ISO 4649 |

| Hardness | 73 | Shore D | ISO 868 |

| Compression (70˚C) | 55 | — | ISO 815 |

| Compression RT | 50 | — | ISO 815 |

| Glass Transistion Temperature | 33 | ˚C | DMA |

| Specific Gravity | 1.23 | g/cm3 | ISO 1183 |

| Tear Strength | 220 | kN/m | ISO 34-1 |

Technical Details & Test Data

- MECHANICAL PROPERTIES

Metric Test Method Print Orientation XY 45/45 YX ZX Ultimate Tensile Strength, MPa ISO 37 36.4 (1.2) 29.7 (0.6) 20.9 (1.5) 27.1 (0.2) Tensile Modulus, GPa ISO 37 0.318 (0.009) 0.291 (0.023) 0.276 (0.011) 0.291 (0.008) Strain at Break, % ISO 37 730 (29) 370 (33) 25 (7) 230 (15) Notched Izod Impact Strength*, kJ/m2 ISO 180/A N N 24 (12)-H 2.3 (0.9)-C - Electrical Properties

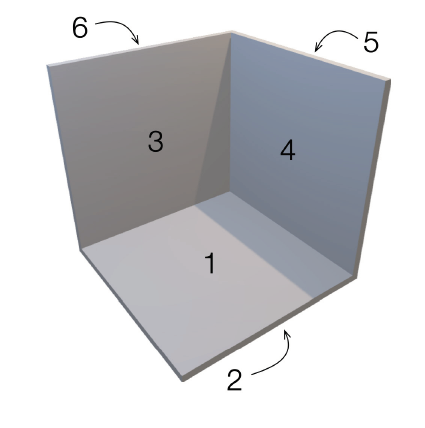

Measurement position Resistance, Ω 100 mm/s @ 295˚C 1

5.10e7 2 1.23e7 3 8.00e2 4 7.90e2 5 8.50e2 6 1.44e3

- MATERIAL HANDLING AND DRYING

Essentium TPU 74D-Z is a very hygroscopic thermoplastic and will rapidly absorb moisture from humid air. Keep the material in the vacuum sealed packaging until you are ready to print with it. TPU 74D-Z filament should always be fed to the printer in a dry container and stored in a dry cabinet. If the material does absorb more than 200ppm moisture, it should be dried in a low dew point (< -40˚C) oven or vacuum oven at 90 – 120˚C for 2 – 3 hours.

RECOMMENDED HSE PRINT SETTINGS

0.4mm Hozzle

Extrusion Width, mm 0.4 – 0.45 Layer Height, mm 0.2 –0.25 Print Speed, mm/s 20 – 200 Infill, % 15 – 75 Hozzle Temperature, ˚C 270 – 330 Bed Temperature, ˚C 70 – 80 IR Temperature, ˚C 20 – 40 Fan Speed, % 10 – 40 0.8mm Hozzle

Extrusion Width, mm 0.75 – 0.85 Layer Height, mm 0.3 –0.35 Print Speed, mm/s 10 – 120 Infill, % 15 – 75 Hozzle Temperature, ˚C 280 – 350 Bed Temperature, ˚C 70 – 80 IR Temperature, ˚C 20 – 40 Fan Speed, % 10 – 60 RECOMMENDED FDM PRINT SETTINGS

Nozzle Temperature, ºC 230 – 250 Bed Temperature, ºC 50 – 80 Print Speed, mm/s 20 – 50 First Layer Speed, mm/s 15 – 20 Fan Speed, % 0 – 20 Bed Material G-10/FR4 or Glass Bed Adhesion Method Magigoo® Flex Infill Density, % <75