Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Technologies

- Product Families

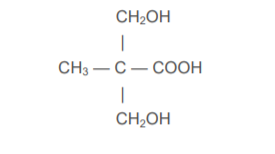

- Chemical structure

Features & Benefits

- Product Information

DMPA® Dimethylolpropionic Acid is a unique and versatile hindered diol molecule with both hydroxyl and carboxyl functionality. The neopentyl structure of this trifunctional compound, having two primary hydroxyl groups and one tertiary carboxylic group, permits simplified processing by allowing the combining of all reactants in a single kettle charge. Good control of the reaction is possible due to the slower esterification rate of the tertiary carboxyl, assuring a uniform distribution of carboxyl groups along the resin backbone. The free acid group actively promotes resin water solubility or water dispersibility after neutralization with a base, easily introduces a polar group to improve coating adhesion and synthetic fiber dye receptivity, and increases the alkali solubility of deposited films. DMPA® is an odorless, free flowing white crystalline solid, which provides superior advantages in the formulation and processing of water soluble resins.

Applications & Uses

- Markets

- Applications

- Coating Type

- Applications

DMPA® is widely used in: Aqueous urethane dispersions, resulting in fast air-drying, high gloss waterborne coatings with superior toughness and flexibility. Water soluble alkyd and polyester resins for improved hydrolytic stability, minimal coupling solvent and improved early water spot resistance in air dried resins. Powder coatings as a modifier for improved gloss, impact resistance and flow properties in epoxy-polyester systems. In polyester blocked isocyanate systems, DMPA imparts a high melting point hydroxyl functional reactive diluent for improved coating flexibility. Epoxy ester coatings, to permit resin formulating flexibility for improved cure response or larger oil strengths, to make resins water soluble, and for electro-deposition resins. Urethane elastomers, as a modifier for improved adhesion to plastics, glass and steel. Electro-deposition coatings, as a high performance neutralizing acid for cathodic electro-deposition and as a source of free acid groups in formulating anodic electro-deposition resins. Nylon / polyester fiber blends for improved compatibility and tear resistance. Lubricating oil additives, as a carrier for thiophosphates or in rust inhibiting derivatives. Photo resists / photo print plates, as a modifier of phenolic and urethane resists for improved alkali solubility and improved resolution in aqueous development systems. Additional data on uses of DMPA® and patent references may be found in “A Complete Guide to the DMPA® Brand of Dimethylolpropionic Acid” which can be obtained from your GEO Specialty Chemicals customer service representative.

Properties

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Molecular Weight | 134.13 | — | — |

| Acid Number | 410 - 415 | mg KOH/g | — |

| Melting Point | 170 - 180 | °C | — |

| Bulk Density | 52.4 | lbs / ft3 | — |

| Flashpoint (Cleveland Open Cup) | 230 | °C | — |

| Water | 11 | — | — |

| Acetone | 2.3 | — | — |

| Ethanol | insoluble | — | — |

| Hydroxyl Content | min. 24.0 | wt % | — |

| Neutralization Equivalent | max. 141.0 | — | — |

| Ash as Na2O | max. 0.03 | wt % | — |

| Moisture | max. 0.3 | wt % | — |

| Water Insolubles ppm | max. 50.0 | ppm | — |

| Color | max. 250 | APHA | — |

| Solvent (25°C) | 220 | g / 100g | — |

Storage & Handling

- Handling & Storage

- Handling & Storage: DMPA® is classified as “DOT not regulated” by the US Department of Transportation and requires no special labeling for shipment. The Harmonized Tariff Code is 2918.19.40 DMPA® should be stored in a clean, dry area, following good warehousing practices.

- Shelf-life: DMPA® has a minimum shelf of not less than 3 years if stored in its original unopened container and under normal storage conditions.