Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Polymer Name

- Composite Materials Functions

- Technologies

Features & Benefits

- Materials Features

- Product Highlights

- High flow matrix.

- Excellent tack life, 60 days at 23°C.

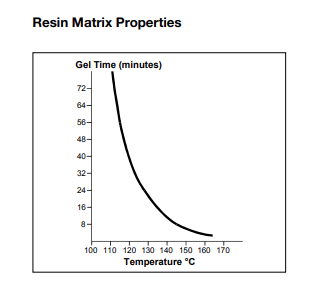

- Versatile cure cycle 120 - 160°C.

- Self extinguishing.

- Excellent service temperature to 200°C.

- Good ablative properties.

Applications & Uses

Properties

- Physical Form

- Cured Properties

| Value | Units | Test Method / Conditions | |

| Inter Laminar Strength (150°C) | 40 | MPa | pr EN2563 |

| Flexural Modulus (150°C) | 65 | GPa | pr EN2562 |

| Flexural Strength (150°C) | 950 | MPa | pr EN2562 |

| Tensile Modulus (150°C) | 70 | GPa | pr EN2561 |

| Tensile Strength (150°C) | 750 | MPa | pr EN2561 |

Technical Details & Test Data

- Curing Conditions

HexPly 200 system can be processed using various cycles, at a pressure between 3 and 7 bar, with a post cure at 160°C for 4 hours.

Temperature (°C) Time 135 90 min 150 30 min

Storage & Handling

- Shelf Life

- Tack life @ 23°C 30 days

- Guaranteed shelf life @ -18°C 12 months (maximum from date of manufacture)