Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Polymer Name

- Composite Materials Functions

- Technologies

Features & Benefits

- Materials Features

- Product Highlights

- Exceptional environmental resistance

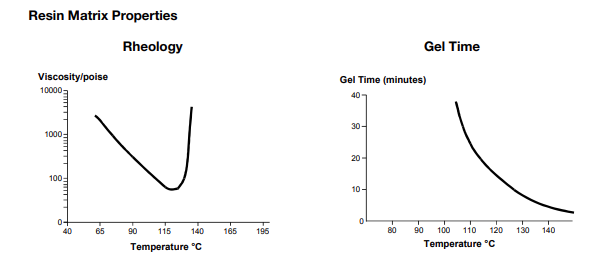

- Controlled minimum viscosity giving easy processing

- Capable of being processed by various techniques

- Good tack and drape characteristics

- Long shelf life and out life at room temperature

- Compatible with Redux 312 adhesive film

Applications & Uses

Properties

- Physical Form

- Cured Properties

| Value | Units | Test Method / Conditions | |

| Cured Density (125°C) | 1.23 | g/cm³ | — |

| Tensile Modulus (125°C) | 3.39 | GPa | ISO R527 type 1 |

| Tensile Strength (125°C) | 65.5 | Mpa | ISO R527 type 1 |

Technical Details & Test Data

- Curing Conditions

60 mins at 125°C and 700kN/m2 (7 bar) pressure. Heat up rate 2°C to 8°C.

Alternative cure cycles:Temperature °C Time (Min) 140 40 150 20 160 10

Components up to 3 mm thick can be cured without a dwell in the schedule provided that the heat-up rate is not more than 5°C/minute. A dwell period is necessary in the heat-up to avoid the occurrence of a resin exotherm (usually 80 - 100°) but the dwell period will depend on the mass and type of tool.

Storage & Handling

- Storage Life

- Tack Life @ 23°C 30 days

- Guaranteed Shelf Life @ -18°C 12 months (maximum from date of manufacture)

Storage conditions.

HexPly® 913 prepregs should be stored as received in a cool dry place or in a refrigerator. After removal from refrigerator storage, prepreg should be allowed to reach room temperature before opening the polythene bag, thus preventing condensation. (A full reel in its packaging can take up to 48 hours).