Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Core Type

- Composite Materials Functions

- Technologies

- Product Families

Features & Benefits

- Materials Features

- Product Highlights

- Commercially available aluminum honeycomb core specifically designed for formability

- Retains mechanical properties in sharp curvatures

- Offers cost savings for curved panels.

- Available in two cell sizes

Applications & Uses

- Applications

- Applications

HexWeb® Aluminum Flex-Core® has been developed by Hexcel to allow the designer and fabricator freedom in the utilization of honeycomb for components requiring simple and compound curvatures. Highly contoured sandwich panels such as leading edges and flaps, nacelles, fairings, doors and access covers, and other parabolic, spherical and cylindrical shapes are prime Flex-Core® candidates. Duplicate die model and control tooling for aerospace use are also examples of Flex-Core® applications. As with standard aluminum honeycomb, Flex-Core® provides controlled crush characteristics without rebound and thus curved energy absorption units become feasible and economical. HexWeb® CR-PAA outperforms standard AMS-C-7438 core in salt spray and crack propagation tests.

Properties

- Specifications

Thickness: Standard tolerance is as follows:

Cut T: inches Tolerance: inches

0.250 – 3.999 in. ±0.005 4.000 – over ±0.062 - HexWeb® Aluminum Flex-Core Mechanical Properties

Typical values (typ) are presented below, as well as minimum average (min) for a product type.

Material/ Cell Count – Gage Nominal Density pcf Compressive Strength

Crush Strength psi Beam Shear Strength

Bare

Strength psiStabilized

L Direction W Direction Strength psi

Modulus ksi Strength psi Modulus ksi Strength psi Modulus ksi typ typ min typ min typ typ typ min typ typ min typ 5052 F40 – .0013 2.1 200 126 225 157 65 80 90 63 18 50 37 10 F40 – .0019 3.1 360 238 395 280 125 165 170 126 32 100 75 13 F40 – .0025 4.1 525 378 560 420 185 250 260 182 43 150 115 17 F40 – .0037 5.7 935 630 1050 700 290 380 400 280 68 230 170 23 F80 – .0013 4.3 524 402 542 455 195 300 196 45 190 120 20 F80 – .0019 6.5 1200 700 1300 735 310 540 308 72 310 180 24 F80 – .0025 8 1600 1100 1750 1120 400 650 434 98 455 260 31 F80 – .0037 12 2700 2300 2600 2200 1500 1450* 1100* 160 1200* 825* 71 5056 F40 – .0014 2.1 240 150 260 182 65 105 74 18 55 42 10 F40 – .0020 3.1 460 284 465 329 125 200 150 32 120 90 13 F40 – .0025 4.1 680 440 740 483 185 310 217 45 200 132 17 F80 – .0014 4.3 780 475 860 518 195 375 235 47 240 138 20 F80 – .0020 6.5 1400 805 1500 910 310 645 364 73 420 213 24 F80 – .0023 8 1800 1210 1950 1260 410 850 518 100 570 307 32 Note - * Results using Beam Shear

Technical Details & Test Data

- Coatings

HexWeb® Aluminum Flex-Core® is available with two types of corrosion-resistant coating. These coating are CRIII and phosphoric acid anodized (CR-PAA™). CR III is an organo-metallic polymer coating that offer protection for aluminum honeycomb exposed to corrosive environments. CR-PAA™ offers superior protection in extreme salt spray environments.

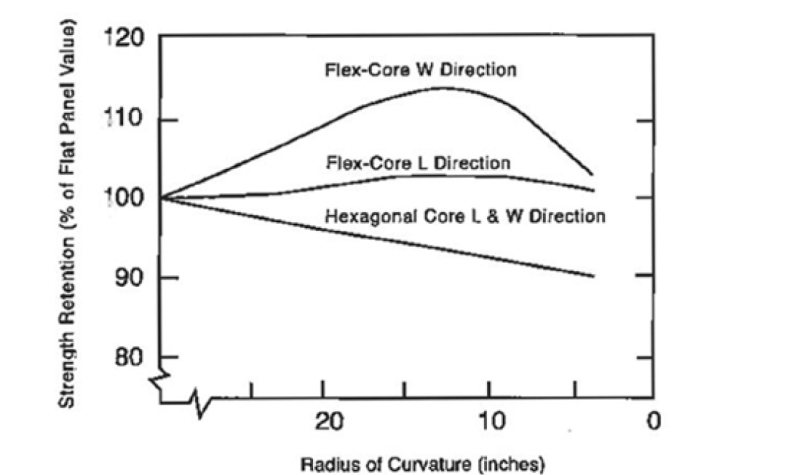

- Effect of Radius Curvature on Shear Strength

Note: This data was derved from 3.8 pcf Hexagonal Core and 4.3 pct Flox-Coro.

Packaging & Availability

- Standard Dimensions

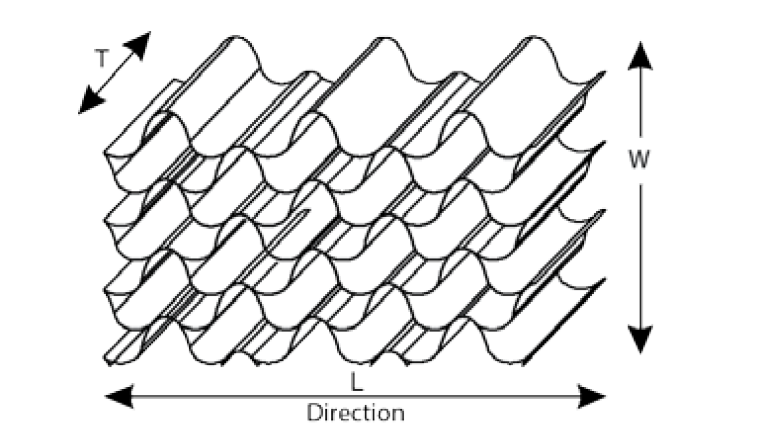

Dimensional Nomenclature

Images for explanation only and do not represent actual appearance.

T = Thickness, or cell depth

L = Ribbon direction, or width

W = Expansion direction, or direction perpendicular to the ribbonHexWeb® Aluminum Flex-Core® is available in the following standard sizes and dimensions in inches with the tolerances indicated:

Product L W T max T min 5052/F40 36”(+2", -0") 96"(+4", -0") 4 0.25 5056/F40 36”(+2", -0") 96"(+4", -0") 4 0.25 5052/F80 36”(+2", -0") 48"(+4", -0") 4 0.25 5056/F80 36”(+2", -0") 48"(+4", -0") 4 0.25 F = Flex-Core

All Flex-Core is cut to T and is not available in HOBE Form.

Special L, W, and T dimensions are available on request.

Note: The high-density materials may not be available at the maximum T dimensions due to expansion limitations.