Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Core Type

- Composite Materials Functions

- Technologies

- Product Families

Features & Benefits

- Materials Features

- Product Highlights

- Aerospace structural grade honeycomb

- Excellent corrosion resistance

- Highest strength and rigidity to weight ratio as a sandwich core

- Maintain corrosion protection at elevated temperatures

- Available in 5052 and 5056 alloys

Applications & Uses

- Applications

- Applications

Aluminum HexWeb® CR III Specification Grade honeycomb materials are predominantly used in sandwich structures to meet design requirements for highly engineered structural components. As a structural core material, it finds applications in all types of aerospace vehicles and supporting equipment where sandwich structure offers rigid panels of minimum weight, aerodynamic smooth surfaces, and high fatigue resistance. The same structural properties are also used for commercial applications such as tools, snow and water skis, bulkheads, and floors. Other nonstructural uses are directional air/fluid flow control, RF shielding, and energy absorption.

Properties

- Mechanical Properties

Mechanical properties of HexWeb® CR III 5052 and 5056 alloy honeycomb are shown in Table I and II, respectively. A major advantage of the HexWeb® CR III organo-metallic polymer coating over typical coatings is that HexWeb® CR III is much more resistant to salt spray exposure combined with a prior elevated temperature exposure. Shear strength retention after 350°F heat aging for up to 500 hours and 30-day salt spray exposure is approximately 88% of room temperature properties with no salt spray exposure; weight loss is considerably less than the maximum permissible per MIL-C-7438 for corrosion resistant aluminum honeycomb.

Table I: HexWeb® CR III 5052 Hexagonal Aluminum Honeycomb

Typical values (typ) are presented below, as well as minimum average (min) for a product type.Cell Size

Nominal Density pcf

Compressive Strength Crush Strength psi

Plate Shear Bare Stabilized L Direction W Direction Strength psi Strength psi Modulus ksi Strength psi Modulus ksi Strength psi Modulus ksi typ typ min typ min typ typ typ min typ typ min typ 1/8 3.1 285 200 300 215 75 130 210 155 45 130 90 22 1/8 4.5 550 375 570 405 150 260 340 285 70 220 168 31 1/8 6.1 980 560 1020 680 240 450 560 455 98 340 272 41 1/8 8.1 1500 1000 1560 1100 350 750 800 670 135 470 400 54 1/8 10 2100p 1575p 2250p 1685p - - 980p 735p 175.0p 550p 415p 65.0p 1/8 12 2700 2100 2900 2200 900 - 1940l 1250l - 1430l 1000l - 5/32 2.6 220 150 240 160 55 90 165 120 37 100 70 19 5/32 3.8 395 285 410 300 110 185 270 215 56 165 125 26.4 5/32 5.3 690 490 720 535 15 340 420 370 84 270 215 36 5/32 6.9 1080 770 1130 800 285 575 590 540 114 375 327 46.4 5/32 8.4 1530 1070 1160 1180 370 800 760 690 140 475 420 56 3/16 2 160 90 175 100 34 60 120 80 27 70 46 14.3 3/16 3.1 290 200 335 215 75 130 210 155 45 125 90 22 3/16 4.4 520 360 550 385 145 250 330 280 68 215 160 30 3/16 5.7 820 560 860 600 220 390 460 410 90 300 244 38.5 3/16 6.9 1120 770 1175 800 285 575 590 540 114 375 328 46.4 3/16 8.1 1600 1000 1720 1100 350 750 725 670 135 480 400 54 1/4 1.6 90 60 100 70 20 40 85 60 21 50 32 11 1/4 2.3 190 120 210 130 45 75 140 100 32 85 57 16.2 1/4 3.4 340 240 370 250 90 150 230 180 50 140 105 24 1/4 4.3 500 350 540 370 140 230 320 265 66 200 155 29.8 1/4 5.2 590 500 760 510 190 335 410 360 82 265 200 35.4 1/4 6 990 630 1100 660 235 430 530 445 96 340 265 40.5 3/8 1 50 20 55 20 10 25 45 32 12 30 20 7 3/8 1.6 90 60 95 70 20 40 85 60 21 50 32 11 3/8 2.3 190 120 200 130 45 75 135 100 32 80 57 16.2 3/8 3 285 190 310 200 70 120 200 145 43 125 85 21.2 3/8 3.7 370 270 410 285 105 180 250 200 55 160 115 26 3/8 4.2 520 335 560 355 135 220 310 255 65 200 150 29 Test data obtained at 0.625 inch thickness

p = preliminary

x = predicted values

I = beam shear for 12.0 pcf products.maximum block size 48 in. x 60 in., maximum thickness = 1.00 in.

Table II: HexWeb® CR III 5056 Hexagonal Aluminum Honeycomb

Typical values (typ) are presented below, as well as minimum average (min) for a product type.Cell Size

Nominal Density pcf

Compressive Strength Crush Strength psi

Plate Shear Bare Stabilized L Direction W Direction Strength psi Strength psi Modulus ksi Strength psi Modulus ksi Strength psi Modulus ksi typ typ min typ min typ typ typ min typ typ min typ 1/8 3.1 320 250 350 260 97 170 250 200 45 155 110 20 1/8 4.5 710 475 690 500 185 320 440 350 70 255 205 28 1/8 6.1 1120 780 1200 825 295 535 690 525 102 400 305 38 1/8 8.1 1750 1200 1900 1300 435 810 945 740 143 560 440 51 5/32 2.6 250 180 265 185 70 120 200 152 37 115 80 17 5/32 3.8 450 360 500 375 140 235 335 272 57 195 155 24 5/32 5.3 820 615 865 650 240 420 550 435 85 325 250 33 5/32 6.9 1220 920 1340 1000 350 650 760 610 118 430 360 43 3/16 2 190 110 200 120 45 75 140 105 27 85 50 13 3/16 3.1 380 250 410 260 97 170 265 200 45 150 110 20 3/16 4.4 620 460 670 490 180 310 425 340 68 245 198 27 3/16 5.7 920 685 1000 735 270 480 565 480 94 330 280 36 1/4 1.6 100 75 110 80 30 50 90 78 20 60 38 10.5 1/4 2.3 240 145 265 155 58 100 180 130 32 100 62 15 1/4 3.4 400 300 480 315 115 200 290 230 50 175 130 22 1/4 4.3 580 440 620 465 172 300 400 325 67 230 190 27 1/4 5.2 790 600 820 645 230 410 490 425 84 300 245 32 3/8 1 55 25 60 35 15 35 55 45 15 35 25 6.8 3/8 1.6 100 75 110 80 30 50 90 78 20 60 38 10.5 3/8 2.3 215 155 225 155 58 100 170 130 32 95 62 15 3/8 3 320 240 340 260 92 160 245 190 43 145 100 19 Test data obtained at 0.625 inch thickness.

Technical Details & Test Data

- Specifications

HexWeb® CR III expanded aluminum honeycomb materials meet the requirements of Military Specification MIL-C7438 where applicable.

Packaging & Availability

- Standard Dimensions

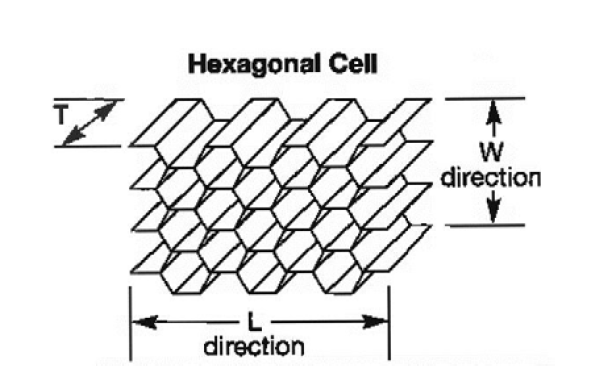

Dimensional Nomenclature

T = Thickness, or cell depth

L = Ribbon direction, or longitudinal direction

W = Transverse direction, or direction perpendicular to the ribbonHexWeb® CR III 5052 and 5056 aluminum honeycomb is available in the following standard size:

On special orders Hexcel has the capability of manufacturing HexWeb® CR III honeycomb panels in the L dimensions up to 60 inches maximum, W dimensions up to 150 inches maximum, and T dimensions up to 34 inches maximum, subject to limitations on some products. Larger sizes may be produced by splicing.

L W Nominal Sq.Ft. 48 in. + 3 in. - 0 in. 96 in. + 4 in. - 0 in. 32 Dimensional Tolerances

Tolerances on cut thickness for standard size and smaller sheets are as follows:Sheet Thickness Standard Tolerances

0.250 in. to 3.999 in. ± 0.005 in. 4.000 in. and over ± 0.062 in.