Knowde Enhanced TDS

Identification & Functionality

- Core Type

- Reinforcement Material

- Composite Materials Functions

- Technologies

- Product Families

Features & Benefits

- Materials Features

- Product Highlights

- High shear properties, due to the ±45 degree fiber orientation

- Small cell size, 1/8 inch minimum hexagonal

- Improved flexibility; damage resistance, and handling characteristics over conventional 0/90 degree fiber construction

- High strength retention at temperatures up to 350°F

- Low moisture pickup

- Low smoke emission

Applications & Uses

- Applications

- Applications

HexWeb® Fibertruss® HFT® is ideally suited for use in structural panels where superior nonmetallic core shear properties and/or minimum deflections are required. Typical applications are airfoil, control surfaces, fairings, engine nacelles, bulkheads, helicopter rotor blades, and equipment trays for motion-sensitive block boxes. HexWeb® Fibertruss® HFT® has also been designed into radomes because of its small cell size, dielectric transparency, and ease of handling. HexWeb® Fibertruss® HFT® honeycomb is designated as follows: Where: Material –Cell Size – Density Example– HFT – 1/8 – 4.0 HFT – designates bias weave fiberglass phenolic honeycomb 1/8 – is the cell size inches 4.0 – is the nominal density in pounds per cubic foot

Properties

- Mechanical Properties

The following mechanical properties are based on testing of products per AMS-STD-401 at 0.500 inch thickness.

Hexcel Honeycomb Designation

Material – Cell – Density

Compressive

StabilizedPlate Shear L Direction W Direction Strength psi Modulus ksi Strength psi Modulus ksi Strength psi Modulus ksi typ min typ typ min typ typ min typ HFT – 1/8 – 3.0 350 270 23 195 150 19 95 75 7.5 HFT – 1/8 – 4.0 560 420 46 315 240 25 150 120 12 HFT – 1/8 – 5.5 900 700 69 525 410 40 250 190 16 HFT – 1/8 – 8.0 1750 1500 100 675 525 45 480 400 21.5 HFT – 3/16 – 2.0 170 130 17 115 90 15 60 50 5 HFT – 3/16 – 3.0 365 275 34 200 155 19 100 80 9 HFT – 3/16 – 4.0 550 460 44 340 270 25 190 140 12 HFT – 3/8 – 4.0 500 400 – 380 290 27 195 140 13

Technical Details & Test Data

- Moisture Pickup

Samples of HexWeb® Fibertruss® HFT® , HRP® , and HRH-10® were exposed to 95% relative humidity at 120°F for 120 hours to determine the moisture pickup. Three specimens each 5 in. L x 6 in. W x 0.50 in. T were first dried for one hour at 200°F, weighed, exposed to 95% R.H. and weighed again. The following percent moisture pickup was measured:

Product Pickup HFT – 1/8 – 4.0 1.30% HFT – 3/16 – 4.0 1.60% HRP – 3/16 – 4.0 1.70% HRH-10 – 3/16 – 4.0 4.40% - Elevated Temperatures

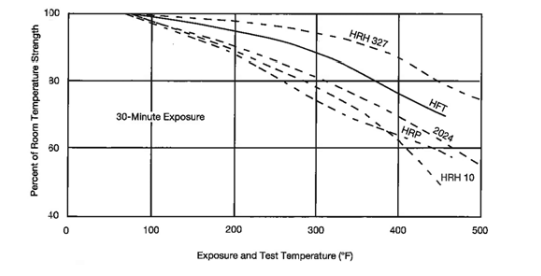

A limited amount of testing at temperatures up to 450°F have shown the shear strength retention of HexWeb® Fibertruss® HFT® to be very good. The ±45 degree fiber orientation helps to maintain good shear properties since the fiberglass is affected less than the resin system. Since the data is limited, it is suggested that the curve below is used as a guide only. Additional testing should be performed if certain properties are required.

Packaging & Availability

- Standard Dimensions

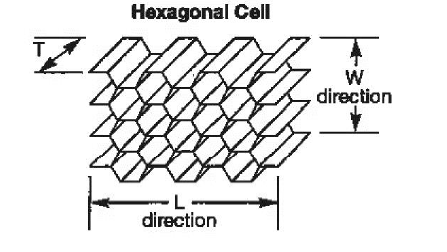

Dimensional Nomenclature

Images for explanation only and do not represent actual appearance.

Standard Dimensions

HexWeb® Fibertruss® HFT® is currently made in standard panel sizes as shown below.

L W Nominal Sq.Ft. HFT Hexagonal 40 in. ± 1 in. 90 in. ± 3 in. 0.125 in. Thickness Tolerance

Tolerances on cut thickness are as follows:

- 0.125 in. to 2.000 in. tolerance will be ± 0.006 in.

- 2.001 in. to 3.000 in. tolerance will be ± 0.010 in.

- 3.001 in. and over tolerance will be ± 0.062 in.