Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Core Type

- Composite Materials Functions

- Technologies

- Product Families

Features & Benefits

- Materials Features

- Product Highlights

- High strength at low densities

- Small cell sizes at low densities

- Damage resistant under normal shop use

- Fire-resistant (self-extinguishing)

- Formable

- Fire-resistant (self-extinguishing)

- Water and fungus resistant

- Excellent dielectric properties

- Good bonding surfaces

- Good thermal and electrical insulator

Applications & Uses

- Applications

- Applications

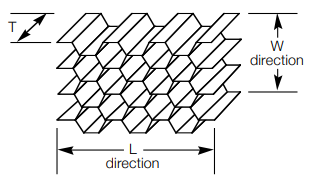

HexWeb® HRH-10 has been widely accepted throughout the aerospace industry and several commercial areas as a very tough, environmentally resistant core material in sandwich panels. It has been designed and used in flat and contoured shapes, with a wide variety of facing materials and adhesives, and it has extensive service in both structural and nonstructural parts. Most of the interior panels of commercial aircraft are made with this core material primarily because of its resilience, small cell size/low density combination, and its fire resistance. Exterior aircraft parts such as radomes, fairings, helicopter blades, flaps, etc., are designed with HRH-10 because of the features listed above. Surfboards and high-performance boats are but two additional applications where this core has been used because of its toughness and resistance to corrosive attack. The OX configuration is a hexagonal honeycomb that has been overexpanded in the W direction, providing a rectangular cell shape that facilitates curving or forming in the L direction.

Properties

- Mechanical Properties

HexWeb® HRH-10 product line and mechanical properties when tested per MIL-STD-401B using 12.7mm core thickness. The typical values represent the mean average of a relatively large number of test values obtained from many blocks of honeycomb.

Hexcel Honeycomb DesignationMaterial – Cell – Density Bare

Strength MPaCompressive Plate Shear Stabilized L Direction W Direction Strength Mpa Modulus Mpa Strength Mpa Modulus Mpa Strength Mpa Modulus Mpa typ typ typ typ typ typ typ Hexagonal HRH-10-3.2-29 0.64 0.79 55 0.62 26 0.34 10 HRH-10-3.2-48 2.07 2.24 138 1.21 41 0.69 24 HRH-10-3.2-64* 3.3 3.97 193 1.76 59 0.97 32 HRH-10-3.2-80 4.8 5.31 255 2.24 70 1.21 37 HRH-10-3.2-96 6.6 7.76 414 2.66 90 1.38 45 HRH-10-3.2-123 10.6 11.3 500 3.1 105 1.7 60 HRH-10-3.2-128 11.55 12.62 538 3.31 110 1.79 66 HRH-10-3.2-144 13.79 14.48 621 3.55 121 2.07 76 HRH-10-4.8-32 1 1.05 76 0.76 30 0.41 14 HRH-10-4.8-48 2.07 2.24 138 1.21 45 0.69 23 HRH-10-4.8-64 3.45 3.72 193 1.69 54 0.97 32 HRH-10-4.8-72 4.4 4.5 250 2.3 75 1.2 35 HRH-10-4.8-96 6.45 7.03 414 2.9 90 1.55 45 HRH-10-6.4-24 0.55 0.62 41 0.48 21 0.24 9 HRH-10-6.4-32 0.97 1.07 76 0.72 28 0.34 14 HRH-10-6.4-50 1.97 2.14 145 1.28 45 0.62 21 HRH-10-6.4-64 3.03 3.31 193 1.72 55 0.86 24 HRH-10-9.5-24 0.66 0.72 41 0.48 21 0.24 10 HRH-10-9.5-32 0.97 1.07 76 0.62 26 0.38 17 HRH-10-9.5-48 2 2.21 117 1.28 39 0.66 24 OX-Core HRH-10/OX-4.8-29 0.76 0.83 48 0.45 14 0.48 21 HRH-10/OX-4.8-48 2.21 2.41 117 0.79 21 0.93 41 HRH-10/OX-4.8-64 4.14 4.48 179 0.9 32 1.03 58 HRH-10/OX-6.4-48 2.41 2.66 117 0.76 21 0.93 41 *Manufactured with various raw material configurations, mechanical properties vary accordingly

Dielectric Constant

Core Density kg/m3 Polarization Parallel to L

Polarization Parallel to W

E Parallel L E Parallel W E Parallel L E Parallel W

24 1.09 1.09 1.04 1.03 32 1.1 1.1 1.05 1.04 48 1.11 1.11 1.07 1.05 64 1.13 1.13 1.1 1.07 80 1.15 1.15 1.14 1.09 96 1.19 1.19 1.18 1.11

Technical Details & Test Data

- Specifications

HexWeb® HRH-10 has been evaluated and approved for numerous specifications. In addition, HexWeb® HRH-10 meets the following parameters and properties: Configuration - The cell size of hexagonal core will give the nominal cell dimensions in mm across the flats (nodes) of the cell. Cell size determination will be made by measuring the length of 10 consecutive cells in 6 random locations and averaging the results. Visual defects (offset sheets, double layers, localized cell distortion, nodal delamination, color variation, resin coat uniformity and surface finish) are inherent to the process and allowable defects as long as density and mechanical properties are obtainable. Anything considered significant or potentially prejudicial will be communicated in advance of delivery for assessment. Density - The tolerance on honeycomb density, when measured on a minimum of 1640 cm3 of core, will be ±10%. Flame Retardance - HexWeb® HRH-10 will meet the “self extinguishing” classification of FAA Air Crash Worthiness Rules and Regulations Section 25.853.* Water Migration - Does not exceed one cell water migration in 24 hours when tested per MIL-STD-401B.

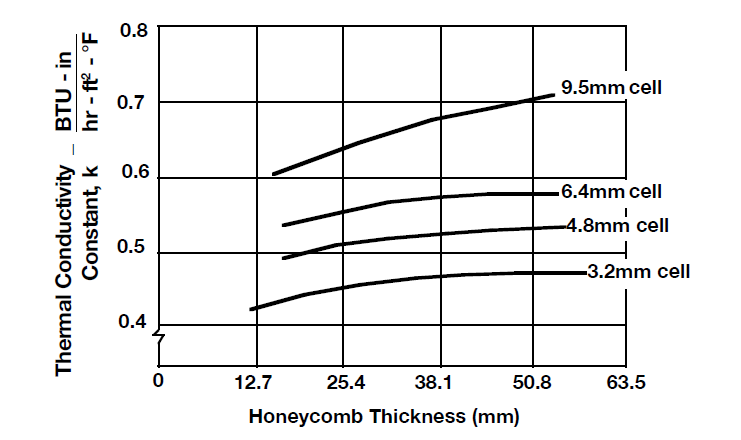

- Thermal Conductivity

Several honeycomb cores have been tested for thermal conductivity. The figure to the right shows the results of this evaluation for HexWeb® HRH-10. The thermal conductivity constant varies with cell size and core thickness because the air convection affects inside the cells. Note the following values were obtained with the heat flow from top to bottom of the panel.

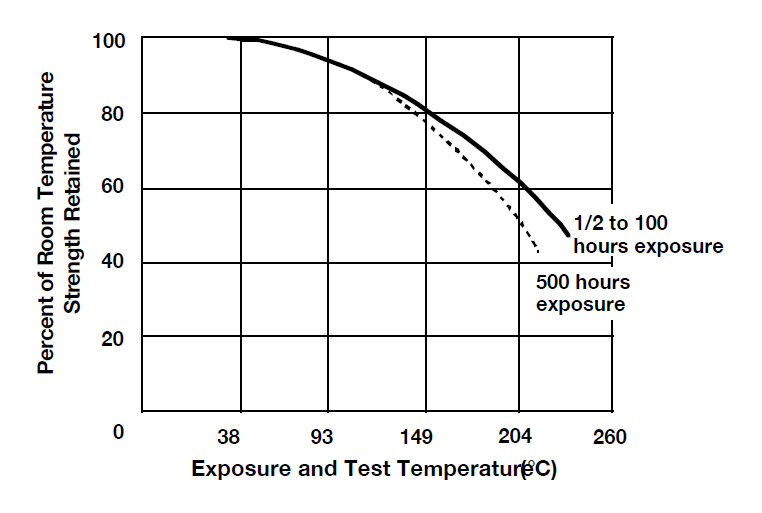

- Properties at Elevated Temperatures

HexWeb® HRH-10 has been tested for shear and compressive strength at elevated temperatures and time exposures up to 500 hours. Because the Nomex softens between 230 to 260°C, the properties drop off rapidly at those temperatures; however, when returned to ambient conditions, most of its original strength is retained.

Packaging & Availability

- Standard Dimensions

HexWeb® HRH-10 honeycomb is typically available in the following sizes.

Products L (+/-50 mm) W (+/-100 mm) T maximum T minimum m2 per Panel All HRH-1 Materials 1250 2500 850 mm 2 mm 3.125 Thickness Tolerance

Tolerances on cut thickness are as follows:

- 3 to 50mm tolerance will be ± 0.125mm

- 50 to 100 tolerance will be ± 0.25mm

- 100mm and over tolerance will be ± 3.0mm

- Tolerance for block purchases will be ± 50.0mm

Different L, W & T tolerances may be available upon special request, subject to review. For large volume requirements it may be possible to supply sheets to your specific size at little or no additional charge. Please be aware tight tolerances are not always possible because of the flexible nature of this material.

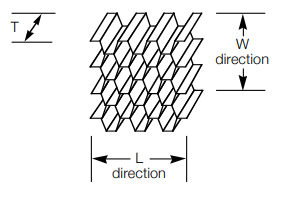

Dimensional Nomenclature

T = Thickness

L = Length in the ribbon direction

W = Width in the direction of expansion, or direction perpendicular to the ribbonHexagonal Cell

Overexpanded Cell