Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Reinforcement Material

- Composite Materials Functions

- Technologies

- Product Families

Features & Benefits

- Materials Features

- Product Highlights

- Specifically designed for formability (cold form)]

- Retains mechanical properties in the curved condition\

- Offer coast savings for curved panels

Applications & Uses

- Applications

- Applications

The HexWeb® Nonmetallic Flex-Core® cell configuration as opposed to the standard hexagonal cell honeycomb provides for exceptional formability into compound curvatures with reduced anticlastic curvature and controlled buckling of the cell wells. When formed into tight radii, HexWeb® Nonmetallic Flex-Core® provides higher shear strengths than comparable hexagonal cores of equivalent density. HexWeb® Nonmetallic Flex-Core® applications exist whenever extreme curvature dictates a flexible cell geometry, e.g. radomes, ducts, leading edges of wings and stabilizers.

Properties

- Mechanical Properties

Test per AMS-STD-401 at 0.500 inch thickness

Hexcel Honeycomb Designation

Material-Cell-DensityCompressive Plate Shear Bare Stabilized L Direction W Direction Strength psi Strength psi Strength psi Modulus ksi Strength psi Modulus ksi typ min typ min typ min typ typ min typ HRP/F35 – 2.5 120 90 140 85 85 72 9.6 45 40 3 HRP/F35 – 3.5 320 245 400 200 200 140 15 105 75 10 HRP/F35 – 4.5 440 340 600 280 280 220 22 140 110 12 HRP/F50 – 3.5 315 225 395 170 170 130 16 90 65 8 HRP/F50 – 4.5 420 340 600 265 265 200 25 140 100 13 HRP/F50 – 5.5 700 540 800 440 440 330 40 235 180 18 HRH-10/F35 – 2.5 200 150 230 110 110 90 4 65 50 2.5 HRH-10/F35 – 3.5 410 320 430 220 220 170 6 120 90 3.7 HRH-10/F35 – 4.5 580 440 620 300 300 230 9 190 150 4.3 HRH-10/F50 – 3.5 380 300 400 175 175 130 5.5 100 75 3.6 HRH-10/F50 – 4.5 565 450 585 330 330 250 9.5 175 140 4.7 HRH-10/F50 – 5.0 670 520 690 380 380 300 10 215 170 5.2 HRH-10/F50 – 5.5 800 620 850 400 400 320 10.5 230 180 5.7 Density Tolerance – Standard tolerance is ±10%. HRH-10 Flex-Core® meets the requirements of SAE specification AMS3713.

Packaging & Availability

- Standard Dimensions

HexWeb® HRP® and HexWeb® HRH-10® Flex-Core® are available in two standard panel sizes.

For HRP:

L W T Min 42 in. ± 1 in. 48 in. ± 1 in. 0.125 in. 42 in. ± 1 in. 72 in. ± 1 in. 0.125 in. For HRH-10:

L W T Min 42 in. + 2 in. -0 in. 48 in. + 2 in. - 0 in. 0.125 in. 42 in. + 2 in. -0 in. 72 in. + 2 in. - 0 in. 0.125 in. Thickness Tolerance

Tolerances on cut thickness are as follows:

- T Min to 1.500 in. tolerance will be ± 0.006 in.

- 1.501 in. to 3.000 in. tolerance will be ± 0.010 in.

- 3.001 and over tolerance will be ± 0.062 in.

Tighter tolerances may be available upon special request.

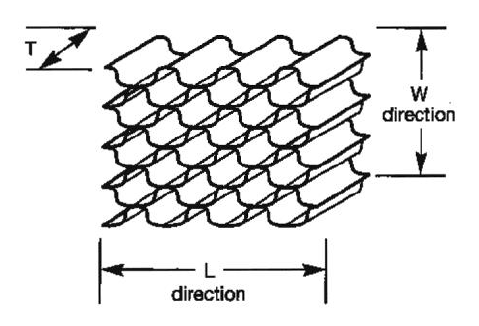

Dimensional Nomenclature

T = Thickness, or cell depth

L = Ribbon direction, or width

W = Long direction, or direction perpendicular to the ribbon

Images for explanation only and do not represent actual appearance.