Knowde Enhanced TDS

Identification & Functionality

- INCI Name

- Cosmetic Ingredients Functions

- CAS No.

- 29118-24-9

- Technologies

- Product Families

Features & Benefits

- Benefit Claims

- Features

It’s time for a fresh perspective about how we can all help preserve our planet without compromising on product performance. Solstice Propellant (HFO-1234ze(E)) is a groundbreaking Earth-friendly1 advancement for aerosol-based face, body, hair, and sun care products.

Not only does Solstice Propellant help keep your products ahead of changing environmental regulations, it provides exceptional formulating benefits such as: - Nonflammable (ASTM E-681, EU A11) – a proven alternative to flammable propellants or to help reduce formulation flammability - Create creamy, shiny, and easy to spread foam - Can be used in combination with Solstice® Enhance and other ingredients to create novel formulations - Excellent compatibility with plastics enables packaging design flexibility - Similar vapor pressure to that of A-46 propellant Based on our breakthrough hydrofluoroolefin(HFO) technology, SolsticePropellant can help reduce climateimpact. With an ultra-low global warmingpotential (GWP) of less than one, it is an environmentally-preferred alternativeto high GWP hydrofluorocarbons(HFCs) such as HFC-152a, HFC-134a, HFC-227ea, and others.Additional environmental benefits include: - Ultra-low GWP < 1 – reduces carbon dioxide equivalent emissions by 99.9% compared to hydrofluorocarbons (HFCs) - Non-ozone-depleting - VOC-exempt (per U.S. EPA and CARB)- Negligible contribution to smog formation This brochure provides technical information about Solstice Propellant including its physical properties, environmental attributes, exposure guidelines, and other important features. The information provided is but some of a mosaic of properties that must be evaluated in assessing candidate ingredients.

Applications & Uses

- Markets

- Applications

- Hair Care Applications

- Skin Care Applications

- Sun Care Applications

- Formulating Advantages with Solstice Propellant

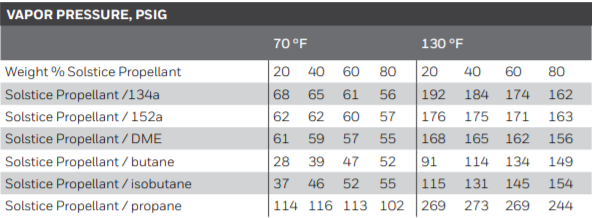

Solstice Propellant is miscible with commonly-used propellants, including hydrocarbons, fluorocarbons, and dimethyl ether (DME) (Tables 4 and 5). Also, Solstice Propellant offers excellent solubility across a wide range of personal care ingredients. It also works well in formulations with zinc oxide and other inorganics. Thus, Solstice Propellant is a preferred choice for formulators seeking flexibility when developing products such as hair sprays, dry shampoos, sunscreen, make-up, barrier creams, body oils, etc.

CREATING A SINGLE-PHASE FORMULATION WITH WATER

As regulations continue to drive VOC levels down in aerosol products, water plays an important role to reduce VOC content in the formulations. With increased use of water, itis important in certain formulations to have single-phase propellant/base systems.For more Details On Single - Phase Formulation Water

Properties

- Physical Form

- Physical Properties

| Value | Units | Test Method / Conditions | |

| Molecular Weight | 114 | g/mol | — |

| Liquid Density (15.6°C) | 1.19 | g/cc | — |

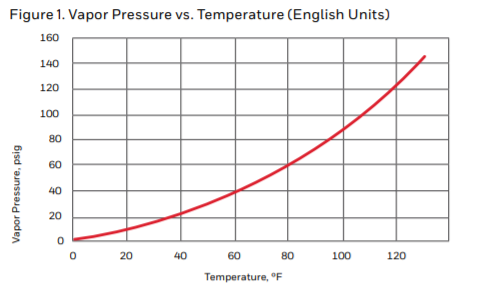

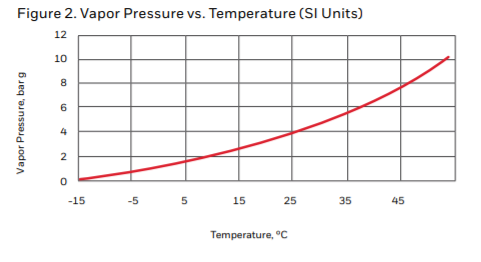

| Vapor Pressure at 21.1°C (70°F) | 3.4 (49.5) | bar g (psig) | — |

| Liquid Density (21.1°C) | 1.17 | g/cc | — |

| Vapor Pressure at 37.8°C (100°F) | 6.2 (89.9) | bar g (psig) | — |

| Vapor Pressure at 54.4°C (130°F) | 10.1 (147) | bar g (psig) | — |

| Boiling Point | -19.0 (-2.2) | °C (°F) | — |

| Specific Gravity of Gas at 15.6°C (60°F) | 3.958 | — | — |

| Volume of Vapor Per liter of liquid at 15.6°C | 0.25 | m3 | — |

| Volume of Vapor Per gal. of liquid at 60°F | 33.02 | ft3 | — |

| Expansion Ratio (Liquid to Gas) at 15.6°C (60°F) | 247 | — | — |

| Specific Heat of Gas, Cp at 15.6°C (60°F) | 0.224 (0.224) | cal/g-°K ( BTU/lb-°R) | — |

| Specific Heat of Liquid, Cp at 15.6°C (60°F) | 0.324 (0.324) | cal/g-°K ( BTU/lb-°R) | — |

| Heat of Vaporization at Boiling | 195 (84) | kJ/kg (BTU/lb) | — |

| Theoretical (Net) Heat of Combustion of Liquid at 21.1°C (70°F) | 10,100 (4,340) | kJ/kg (BTU/lb) | — |

| Viscosity of Liquid, Centipoises at 37.8°C (100°F) | 0.171 | — | — |

| Solubility in Water, % by Weight at 21.1°C (70°F) | 0.037 | — | — |

| Solubility of Water, % by Weight at 21.1°C (70°F) | 0.022 | — | — |

| Surface Tension, dynes/cm at 21.1°C (70°F) | 10.1 | — | — |

| Kb (Kauri-butanol) Value | 12.5 | — | — |

| Stable pH Range4 10 days at 40°C (104°F) | max. 12 | — | — |

Technical Details & Test Data

- Excellent Materials Compatibility

Solstice Propellant is compatible with most materials commonly used in the personal care industry. Preferred gasket materials for use with Solstice Propellant are polytetrafluoroethylene (PTFE) and PTFE-encapsulated Viton®5. Solstice Propellant has been found to be generally compatible with grades of buna, butyl rubbers, and neoprene. Tests show that Solstice Propellant is also compatible with most plastics, except acrylics. It is important to recognize that results may vary with different grades and manufacturers of the same polymer. Therefore, when evaluating a material for compatibility with Solstice Propellant, it is recommended that the manufacturer be consulted, or further independent testing be completed. Results shown in Table 6 should be used only as a guide.

COMPATIBLE WITH MOST METALS

Honeywell has tested the compatibility of Solstice Propellant with commonly-used metals, including carbon steel, stainless steel, copper, brass, and aluminum. The test results showed no measurable impact on Solstice Propellant purity. Further, Honeywell and third-party tests12 shows Solstice Propellant to be stable when combined with various common refrigeration lubricants and coupons of the above metals in the presence of up to 500 ppm moisture and 2,000 ppm air in sealed glass tubes at 175°C (347°F) for 14 days. Although Solstice Propellant has been shown to be compatible with aluminum in thermal stability tests, exposure to finely divided aluminum or freshly abraded aluminum surfaces should be avoided.HIGH THERMAL AND HYDROLYTIC STABILITY

Honeywell has studied the thermal and hydrolytic stability of pure Solstice Propellant up to 110°C (230°F) in the presence of common materials of construction, including steel (carbon and stainless), copper, and aluminum. It was found to be stable. Further, Honeywell and third-party tests12 show Solstice Propellant to be thermally and hydrolytically stable using the same test parameters noted in the compatibility testing of metals.Table 6. Compatible with Commonly Used Plastics and Elastomers

SUBSTRATE AVG. % CHANGE IN WEIGHT AVG. % CHANGE IN VOLUME ABS 0.21 -0.6 Acrylic Extremely Distorted Substrate Buna-Nitrile -4.95 -7.18 Butyl Rubber 1.27 0.88 Delrin® Aceta6 0.18 -0.48 EPDM -2.0 -2.49 Epichlorohydrin 0.73 1.51 HDPE 0.82 -3.74 HIPS 0.26 -0.45 Kalrez® 6375 -7 5.22 33.0 Kynar® PVDF8 0.21 0.0 Natural Rubber (Gum) -0.64 -0.75 Neoprene -7.7 -11.47 Nylon 66 -0.26 0.0 PEEK -0.02 -0.14 Polycarbonate 1.1 0.77 Polyethylene

terephthalate (PET)-0.01 0.0 Polypropylene 0.83 0.0 PVC-Type 1 0.002 -0.44 SBR/CR/NBR 2.0 -4.31 Silicone -1.57 -1.96 Teflon®PTFE9 2.03 2.43 Texin® (Thermoplastic)10

Polyurethane 3905.14 4.41 Ultem® Polyetherimide11 -0.04 0.0 Viton® B Comm. Grade5 4.43 5.71 - Compatible With Common Aersol Packaging Materials

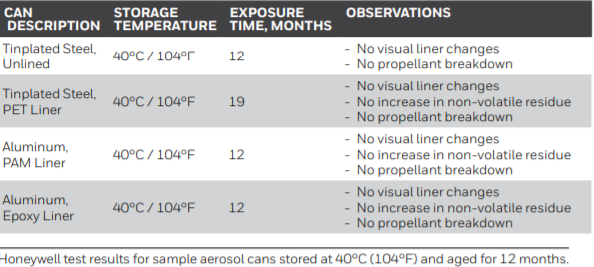

Aerosol Cans:Honeywell tests show Solstice Propellant to be compatible with common types of aerosol cans. Sample cans were stored at 40°C (104°F) to simulate an accelerated aging process. After aging for 12 months, the cans were visually inspected for signs of corrosion or liner degradation, and the propellant was analyzed for evidence of chemical breakdown (Table 7). In longterm storage tests, no visual liner changes were observed in tinplated steel, PETlined aluminum, polyacrylamide (PAM)-lined aluminum, or epoxy-lined aluminum cans filled with Solstice Propellant.

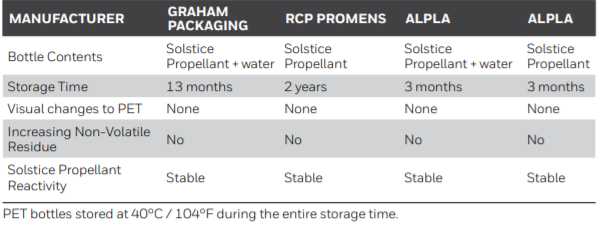

Plastic Aerosol Bottles:Due to its nonflammability and moderate vapor pressure, Solstice Propellant is currently the only liquefied gas propellant which may be used in plastic aerosol bottles. In addition, Solstice Propellant diffuses much more slowly through PET bottles than compressed gasses.

Aerosol Valves:Solstice Propellant valve compatibility studies were performed by Precision Global14 and Summit Packaging Systems.15 Good compatibility was seen with grades of buna, butyl rubbers, and neoprene. In addition, an Aptar Pharma study of Solstice Propellant with its metered-dose inhaler valves concluded that the compatibility of Solstice Propellant was equivalent to that of HFC- 134a and HFC-227ea.16.

Bag-On-Valve (BOV):The compatibility of Solstice Propellant with laminated BOV pouches was tested by Summit Packaging Systems.15 BOV pouches containing water as the surrogate product were pressurized with SolsticePropellant. Periodic testing included vapor pressure measurements and examination of the bags for signs of delamination. After 12 months at room temperature, 4-ply polyethylene and 4-ply polypropylene laminated BOV pouches showed the best results for long-term stability, with minimal vapor pressure loss and no delamination of the pouch. For assistance with valve selection, consultation with a supplier is recommended.

For More Details on On Compatible With Common Aersol

Safety & Health

- Environmental Health and Safety

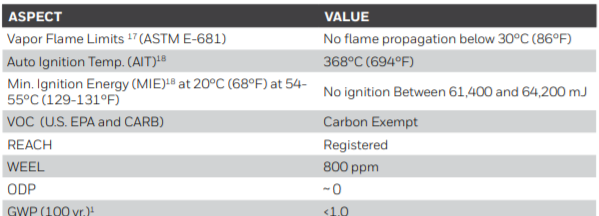

Solstice Propellant is nonflammable (ASTM E-681, EU A11), non-ozonedepleting (ODP ~ 0), and has an ultralow global warming potential (GWP<1). Solstice Propellant exhibits no vapor flame limits below 30°C (86°F) (Table 9). The results of extensive toxicity tests support the conclusion that Solstice Propellant exhibits a very low order of toxicity. Accordingly, the American Industrial Hygiene Association (AIHA) has assigned a Workplace Environmental Exposure Limit (WEEL) of 800 ppm (8- hour time-weighted average).19 Solstice Propellant has a low environmental half-life (16.4 days atmospheric lifetime vs 1.5 years for HFC-152a). The final decomposition products are not new and at levels much lower than naturally present. These decomposition products are then rained out and mineralized with no additional effect on ozone or on climate.20 During decomposition, no trifluoroacetic acid (TFA) is formed. Solstice Propellant has not been tested for use in every personal care formulation, and it is the customer’s responsibility to determine whether it is appropriate for use in its specific formulation and to conduct required tests. Additional information is available upon request.

Packaging & Availability

- Packaging Type

Storage & Handling

- Safe Use and Handling

Before handling or using Solstice Propellant, Honeywell recommends carefully reviewing the information in the Safety Data Sheet (SDS).

The SDS may be viewed online at the Honeywell SDS Resource Center: www.honeywellmsds.com.

Copies of the SDS may also be obtained by contacting Honeywell at 1-800-631-8138 within the U.S. and Canada, or by contacting the local Honeywell sales office. Solstice Propellant is supplied in cylinders that meet U.S. Department of Transportation (DOT) requirements and comply with all applicable codes and regulations for the regions in which they are transported. Store Solstice Propellant packaged cylinders in a dry, ventilated, enclosed area away from heat, flame, corrosive chemicals or fumes, and explosives. Avoid direct sunlight, particularly in warm weather. The Solstice Propellant 10-lb. sample returnable cylinder outlet has a CGA 165 fitting which accepts a standard 1/4” S.A.E. 45° flare connector. This is a common refrigeration fitting. Other packaging options are also available.