Knowde Enhanced TDS

Identification & Functionality

- Flavor

- Flavor Ingredient Class

- Ingredient Name

- Food Ingredients Functions

- Ingredients

- Hops Extract

- Technologies

- Product Families

Features & Benefits

- Food Ingredients Features

- Product Highlights

- CO2 Extract is produced through the extraction of hop pellets with food-grade carbon dioxide in a liquid or supercritical form.

- CO2 Extract contains alpha acids, beta acids and essential oils and can be used to partially or entirely replace leaf hops or hop pellets in the brewing process.

- CO2 Extract offers a concentrated and practical alternative to leaf hops or hop pellets. Moreover, CO2 Extract has a long shelf life.

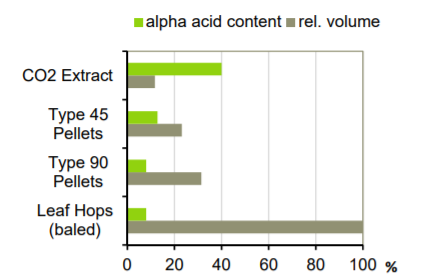

Comparison of the volumes of various hop product(8 % alpha acids) alpha acid content rel. volume.

- Product Information

- Appearance

Golden green to amber in color, CO2 Extract is a thick syrup (depending on the hop variety and extraction conditions) that becomes more fluid when warmed.

- Utilization

If CO2 Extract is boiled for at least 50 minutes, utilization within the range of 32 – 38 % can be expected. Actual utilization will vary from brewery to brewery due to differences in equipment and process conditions.

• Flavor

The flavor characteristics of the original hops are almost completely retained in CO2 Extract. Early additions of CO2 Extract during wort boiling mainly serve to impart bitterness.

• Chemical Residues

Nitrates and heavy metals are almost entirely eliminated in CO2 Extract. In addition, many pesticide and fungicide residues are largely removed by the CO2 extraction process.

• Quality

All Hopsteiner® products are processed in facilities which fulfill internationally recognized quality standards.

Applications & Uses

- Markets

- Applications

- Food & Nutrition Applications

- Product Use

CO2 Extract is typically added to the wort kettle as a complete or partial replacement for leaf hops or hop pellets.

• Dosage

Kettle additions of CO2 Extract are based on the concentration of alpha acids, an estimated or known utilization and the desired intensity of bitterness in the beer.

• Addition

For the highest possible utilization, CO2 Extract should be added early in the wort boiling process. CO2 Extract is not very suitable for late hop additions due to its nonpolar character. However, in this situation, better results can be achieved with pre-isomerized kettle extracts such as IKE or PIKE, products that are more soluble in wort.

Pre-warming cans of CO2 Extract is not necessary. Suspending punctured cans in the boiling wort will ensure that all of the extract is completely flushed out into the kettle.If CO2 Extract is added by means of automatic dosing units, it should be warmed to 45 °C (113 °F) and gently mixed to ensure perfect dosing.

Properties

- Physical Form

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Alpha acids | max. 65 | % | — |

| Beta acids | max. 30 | % | — |

| Hop oil | 3 – 12 | % | — |

| pH | 3.5 - 4.5 | — | — |

| Viscosity at 45 °C (113 °F) | 200 – 400 | mPas | — |

| Density at 20 °C (68 °F) | 0.9 – 1.0 | g/ml | — |

Technical Details & Test Data

- Analytical Methods

- Concentration of Bitter Substances Alpha and beta acids can be measured using the following methods:

- HPLC according to Analytica-EBC 7.7 or

ASBC Hops-14 with the current ICE standard

-

- spectrophotometric method according to ASBC Hops-8 (I)

The lead conductance value can be measured using the following methods:

-

- Analytica-EBC 7.6

- ASBC Hops-8 (II)

• Concentration of Hop Oil

The hop oil concentration can be measured using the following methods:

-

- Analytica-EBC 7.10

- ASBC Hops-13

- Concentration of Bitter Substances Alpha and beta acids can be measured using the following methods:

- Technical Support

We are pleased to offer assistance and advice on the full range of Hopsteiner® products:

- copies of all relevant analytical procedures

- Safety Data Sheets (SDS)

- assistance with pilot or full-scale brewing trials

- special analytical services

Disclaimer: The information provided in this document is believed to be correct and valid.However, Hopsteiner® does not guarantee that the information provided here is complete or accurate and thus assumes no liability for any consequences resulting from its application.

Safety & Health

- Safety

CO2 Extract is a natural product and may be safely handled using routine precautions to avoid contact with skin and, in particular, the eyes. Any product coming into contact with the skin should be immediately washed off with soap and water or an appropriate hand cleanser. If CO2 Extract gets into the eyes, flush with copious amounts of water until clear and seek medical attention.For full safety information, please refer to the relevant Hopsteiner® safety data sheet.

Packaging & Availability

- Packaging

CO2 Extract can be packaged in cans, pails and drums according to customer requirements:

Cans: 0.5 to 4 kg (USA)

0.5 to 4.2 kg (Germany) Pails: 4 to 20 kg (USA only) Drums: 50 and 200 kg

CO2 Extract can be produced to any alpha acid concentration desired by our customers and packaged in cans (e.g. 450 g of alpha acids per can).

Alternatively, the alpha acid content of CO2 Extract can be standardized to any given concentration using glucose syrup (non- GMO glucose cannot be guaranteed). The container is then filled to a standard weight (e.g. 30 % alpha acids in 1 kg cans).

Storage & Handling

- Storage

CO2 Extract should be stored in sealed containers at temperatures < 10 °C (50 °F). Opened containers should be used within a few days.

• Best Before Date

CO2 Extract is stable for eight years from the date it was produced / packaged if stored under the recommended conditions.