Knowde Enhanced TDS

Identification & Functionality

- Flavor

- Flavor Ingredient Class

- Ingredient Name

- Food Ingredients Functions

- Ingredients

- Beta Acid, Hop Oil, Alpha Acids, Iso-Alpha Acids, Rho Iso-Alpha Acids

- Technologies

- Product Families

Features & Benefits

- Product Highlights

- Light Stable Kettle Extract (LSKE) is produced from CO2 extract and can be used as a complete replacement for regular kettle extract in the brewing process.

- LSKE contains reduced (rho) isomerized alpha acids (in their potassium salt form), beta acids and hop essential oils.

- LSKE provides substantial protection against lightstruck flavor when used as the sole source for bitterness.

- LSKE is the only light stable hop product which can be added during wort boiling , contributing to both, bitterness and hop aroma.

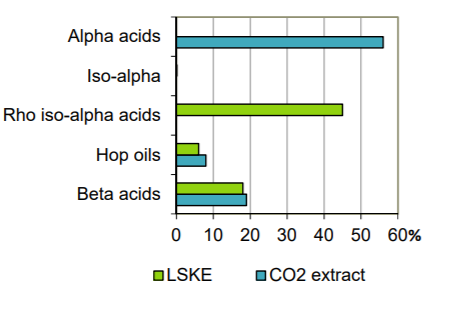

Typical comparison of primary compounds in LSKE & CO2 extract

- Product Information

- Appearance

Reddish or yellow-green in color, LSKE is a thick syrup that becomes more fluid when warmed.

- Utilization

Based on HPLC analysis of the finished beer, utilization of rho iso-alpha acids within a range of 45 – 55 % can be expected. Utilization is likely to be at least 50 % higher than that achieved with regular CO2 extracts.

Late additions of LSKE greatly enhance hop

oil retention.Actual utilization will vary from brewery to brewery due to differences in equipment and process conditions.

• Light Stability

LSKE only provides protection against lightstruck flavor in the complete absence of alpha acids and iso-alpha acids. LSKE can be used in conjunction with any Hopsteiner® light stable product to achieve light stability.

• Flavor

Unlike other rho iso-products added post- fermentation, the flavor characteristics of LSKE are similar to those of regular CO2 extract. The additional presence of both beta

acids and hop oils in this extract imparts a more rounded and fuller flavor to beer.Compared to regular iso-alpha acid products, reduced iso-alpha acids (rho) lend a smoother, non-lingering bitterness to beer.Depending on the total bitterness and type of beer, the intensity of the bitterness of rho iso-alpha acids is 60 to 70 % of that achieved with regular iso-alpha acids. Thus, the sensory factor of rho iso-alpha acids is0.6 – 0.7 times the bitterness of iso-alpha acids at a value of 1.0. If added at the end of the boil, LSKE imparts a typical late hop aroma to the beer.

• Chemical Residues

Nitrates and heavy metals are almost entirely eliminated in LSKE. In addition, pesticide residues are also largely removed by the CO2 extraction process.

• Quality

All Hopsteiner® products are processed in facilities which fulfill internationally recognized quality standards.

Applications & Uses

- Markets

- Applications

- Food & Nutrition Applications

- Product Use

LSKE is typically added to the wort kettle as a complete or partial replacement for any other light stable hop product. Furthermore the dosage of LSKE during wort boiling reduces the risk of bacterial infection.

• Dosage

Kettle additions of LSKE are based on the concentration of rho iso-alpha acids, an estimated or known utilization, the sensory factor of rho iso-alpha acids and the desired intensity of bitterness in the beer.

• Addition

LSKE can be added in a manner similar to regular kettle extracts. For instance, LSKE can be added in the kettle when the transfer of lauter wort to the kettle commences, at the beginning of the boil or up to five minutes before casting out the wort.

Pre-warming cans of LSKE is not necessary. Suspending punctured cans in the boiling wort will ensure that all of the extract is completely flushed out into the kettle.

If LSKE is added by means of automatic dosing units, it should be warmed to 50 - 60 °C (122 - 140 °F) and gently mixed to ensure perfect dosing.

• For Light Stable Beer

For maximum protection against lightstruck flavor, it is essential that no other sources of non-reduced iso-alpha acids are inadvertently introduced into the wort or beer. Therefore, the following must be carefully implemented:

-

- exclusive use of light stable hop productsthroughout the entire process

-

- avoid contamination through equipment surfaces previously in contact with regular iso-alpha acids

- never pitch wort with yeast that has beenin contact with regular alpha and iso- alpha acids

-

Properties

- Physical Form

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Rho iso-Alpha acids | 35 – 45 | % | — |

| pH (In Water) | 7.5 – 8.0 | — | — |

| Iso-Alpha acids | below the detection limit | — | — |

| Alpha acids | below the detection limit | — | — |

| Beta acids | 12 – 30 | % | — |

| Hop oil | 3.2 – 10.0 | % | — |

| Viscosity at 50 °C (122 °F) | 200 – 600 | mPas | — |

| Density at 20 °C (68 °F) | 1.05 – 1.10 | g/ml | — |

Technical Details & Test Data

- Analytical Methods

- Concentration of Bitter Substances The concentrations of rho iso-alpha acids, beta acids and residual iso-alpha and alpha acids can be measured using the following

methods:

- HPLC according to Analytica-EBC 7.8 and 7.9

• Concentration of Residual Hop Oil

The hop oil concentration can be measured using the following methods:

-

- Analytica-EBC 7.10

- ASBC Hops-13

• Concentrations of Reduced Iso-Alpha Acids in Beer

The concentration of reduced iso-alpha acids in beer can be measured by HPLC according to Analytica-EBC 9.47.

Note:It is possible that analysis results for the corresponding value for bitterness must be adjusted. The factor used in this analysis will result in lower values if reduced hop products were used as the exclusive source for bitterness or in higher amounts.

- Technical Support

We are pleased to offer assistance and advice on the full range of Hopsteiner® products:

-

- copies of all relevant analytical procedures

- Safety Data Sheets (SDS)

- assistance with pilot or full-scale brewing trials

- special analytical services

Disclaimer: The information provided in this document is believed to be correct and valid.However, Hopsteiner® does not guarantee that the information provided here is complete or accurate and thus assumes no liability for any consequences resulting from its application.

-

Safety & Health

- Safety

LSKE is derived from natural raw materials and may be safely handled using routine precautions to avoid contact with skin and, in particular, the eyes. Any product coming into contact with the skin should be washed off immediately with soap and water or an appropriate hand cleanser. If LSKE gets into the eyes, flush with copious amounts of water until clear and seek medical attention. For full safety information, please refer to the relevant Hopsteiner® safety data sheet.

Packaging & Availability

- Packaging

LSKE can be packaged in cans, pails and drums according to customer requirements: Cans: 0.5 to 4 kg (USA)0.5 to 4.2 kg (Germany) Pails: 4 to 20 kg (USA only) Drums: 50 and 200 kg

LSKE can be produced to the rho iso-alpha acid concentration desired by our customers and packaged in cans (e.g. 450 g of alpha acids per can).

Storage & Handling

- Storage

• Storage

LSKE should be stored in sealed containers at temperatures < 10 °C (50 °F). Opened containers should be used within a few days.

• Best Before Date

LSKE is stable for six years from the date it was produced / packaged if stored under the recommended conditions.