Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Chemical Name

- CASE Ingredients Functions

- Composite Materials Functions

- Fluids & Lubricants Functions

- Industrial Additives Functions

- CAS No.

- 694-83-7

- EC No.

- 211-776-7

- Technologies

- Product Families

- Molecular Structure

Features & Benefits

- Industrial Additives Features

Applications & Uses

- Applications

- Applicable Processes

- Compatible Substrates & Surfaces

- Fluids & Lubricants Type

- Composites End Use

- Industrial Additives End Use

- Epoxy Curatives

Epoxy resins cured with Dytek® amines have excellent properties for use in coatings, civil engineering, adhesives, marine, and composite applications.

Features Typical Applications - Low viscosity vs. IPDA

- Chemical resistance

- Highest Tg of all Dytek® Amines

- Tank linings with chemical exposure

- High temperature applications

- Wind turbine blades

- High-performance composite parts

- Applications

Chelating Agent

- Oilfield

- Textiles

- Water treatment

- Detergents

Epoxy Curing Agents

- Composites

- Flooring/paving

Herbicide intermediates

Polyamide Resin

- Adhesives

- Coatings

- Films

- Plastics

- Inks

Polyurethane/Polyurea

- Extenders

- Catalysts

Scale/Corrosion Inhibitors

Properties

- Physical Form

- Appearance

- Clear and free of suspended materials

- Odor

- Amine like

- Miscible In

- Water

- Typical Properties

| Value | Units | Test Method / Conditions | |

| 1,2-Diaminocyclohexane Content | 99 | wt% | — |

| 2-Methylpentamethylenediamine Content | 0.1 | wt% | — |

| Amine Value | 967 | mgKOH/g | — |

| Color | 15 | APHA | — |

| Critical Pressure (Pc) | 43.4 | atm | — |

| Critical Temperature (Tc) | 409.2 | °C | — |

| Critical Vapourization (Vc) | 361.5 | mL | — |

| Flash Point | 75 (167) | °C (°F) | Closed Cup |

| Hansen Solubility Parameters (δ) | 11 | — | — |

| Hansen Solubility Parameters (δd) | 8.6 | — | — |

| Hansen Solubility Parameters (δH) | 5.8 | — | — |

| Hansen Solubility Parameters (δp) | 3.5 | — | — |

| Heat of Vaporization (at 185°C) | 106 | cal/g | — |

| Hexamethylenediamine Content | 0.1 | wt% | — |

| Hydrogen Equivalent Weight | 28.5 | — | — |

| Melting Point (Cis) | 2 (36) | °C (°F) | — |

| Melting Point (Trans) | 15 (59) | °C (°F) | — |

| Molecular Weight | 114 | — | — |

| pH (5% Aqueous Solution) | 12 | — | — |

| pKa1 (at 30°C (86°F)) | 9.6 | — | — |

| pKa2 (at 30°C (86°F)) | 6.1 | — | — |

| Refractive Index (cis, n25 D) | 1.487 | — | — |

| Specific Gravity (at 20°C (68°F)) | 0.94 | — | — |

| Viscosity (at 21°C (70°F)) | 7.2 | cP | — |

| Volatiles Content | 100 | % | — |

| Water Content | 0.1 | wt% | — |

| Tg, (DSC, 2nd run) | 176 | °C | — |

| HDT | 94 | °C | — |

| Izod Impact Strength Unnotched | 5.9 | ft-lbf/in2 | — |

| Charpy Impact Strength | 4.8 | ft-lbf/in2 | — |

| Flexural Strength (X 103) | 12.8 | psi | — |

| Elasticity Modulus (X 103) | 439 | psi | — |

| Tensile Strength (X 103) | 4.4 | psi | — |

| Elongation at Break | 2.4 | % | — |

| Vapor Pressure (at 20°C) | 0.387 | mm Hg | — |

| Hardness | 86 | Shore D | — |

Technical Details & Test Data

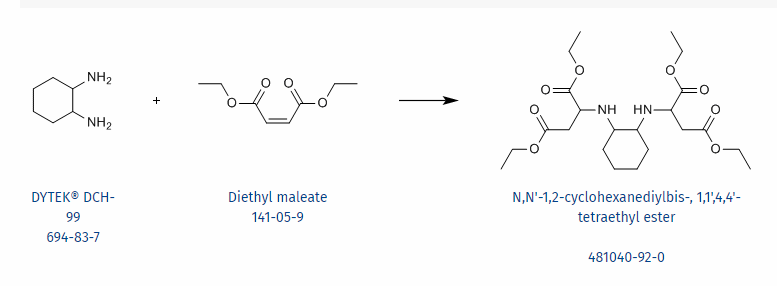

- Aspartic Esters