Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Base Chemicals Functions

- Technologies

Features & Benefits

- Advantages

- Permits higher solids solutions at a given viscosity and temperature, or lower solution viscosities at the same solids content and temperature as compared with Elvanol™ 71-30.

- Suggested to be used wherever higher viscosity, fully hydrolyzed polyvinyl alcohols are desired, but a lower solution viscosity is needed, particularly useful as a pigment binder for ceiling tile primers.

- Elvanol™ 90-50 has viscosity similar to starches used in metering size presses at line speeds in excess of 1500 meters per minute.

Applications & Uses

- Applications

- Applicable Processes

- Recommended Applications

Elvanol® 90-50 is suggested for evaluation wherever the high film strength and oil, grease, and solvent resistance associated with higher viscosity, fully hydrolyzed polyvinyl alcohols are desired, but a lower solution viscosity is needed. For example, it should be useful in such applications as paper coating and sizing, adhesives for porous substrates including paper and paperboard, hot-watersoluble film, and as a binder for pigments or other sold particles. Elvanol® 90-50 is particularly useful as a pigment binder for ceiling tile primers.

Properties

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Viscosity (20°C (68°F), 4wt% aqueous) | 11.6 - 15.4 | cps | — |

| Degree of Hydrolysis | 99.5 | mol % | — |

| Ash Content (Sodium oxide) | max. 0.7 | % | — |

| Residual Methanol Content | max. 1.0 | wt % | — |

| pH | 5.0 - 7.0 | - | — |

| Volatiles Content | max. 5.0 | wt % | — |

Regulatory & Compliance

- FDA Status

Elvanol® 90-50 polyvinyl alcohol complies with U.S. Food and Drug Administration (FDA) Regulations under the following Sections of Title 21 CFR, and may be used in contact with food, subject to the limitations and requirements therein:

- 175.105 - Adhesives

- 175.300 - Resinous and polymeric coatings

- 175.320 - Resinous and polymeric coatings for polyolefin films

- 176.170(b) - Components of paper and paperboard in contact with aqueous and fatty foods

- 176.180 - Components of paper and paperboard in contact with dry food

- 177.1200 - Cellophane

- 177.1670 - Polyvinyl alcohol film

- 177.2260 - Filters, resin-bonded

- 177.2800 - Textiles and textile fibers

Technical Details & Test Data

- Resin Characteristics

This polyvinyl alcohol provides tensile and adhesive strength approaching that of the medium viscosity, fully hydrolyzed commercial grade, Elvanol® 71-30. Elvanol® 90-50 permits higher solids solutions at a given viscosity and temperature, or lower solution viscosities at the same solids content and temperature as compared with Elvanol® 71-30.

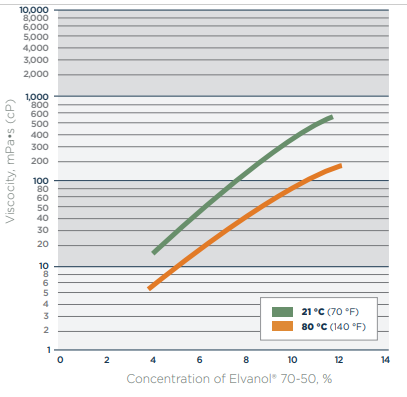

- Effects of Concentration on Viscosity

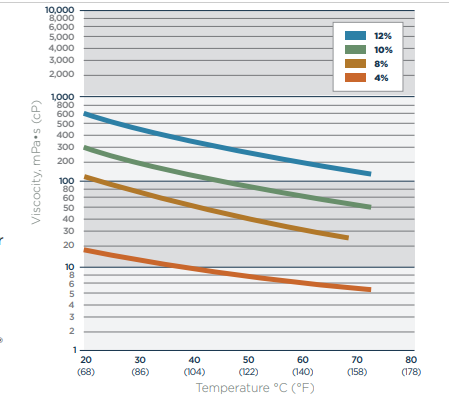

- Viscosity vs Temperature

Storage & Handling

- Safety and Handling

Elvanol® 90-50 is technical quality polyvinyl alcohol. It is not recommended for inclusion in any food or preparation that might be taken internally

Elvanol® may be disposed of by incineration or landfill. However, any disposal method must be in compliance with all applicable local, state and federal regulations.