Knowde Enhanced TDS

Identification & Functionality

- Plastics & Elastomers Functions

- Technologies

- Product Families

- Carrier Resin

Polyolefinic

Features & Benefits

- Materials Features

- Highlights

Numerous polymers are available in the world. These polymers are different from each other in respect of long term heat stability, processing stability, applications and properties. Most of the polymers are sensitive to oxidative degradation at elevated temperature. Due to degradation, following defects can occur in the final product:

- Surface Cracks

- Loss of mechanical properties

- Discoloration

- Loss of gloss

- Benefits

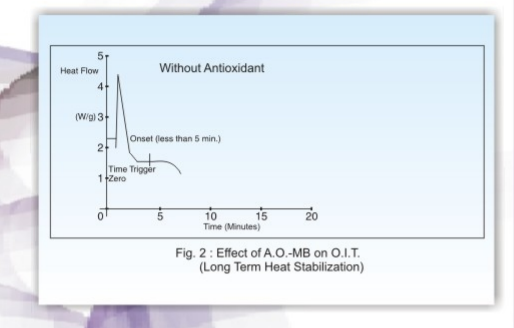

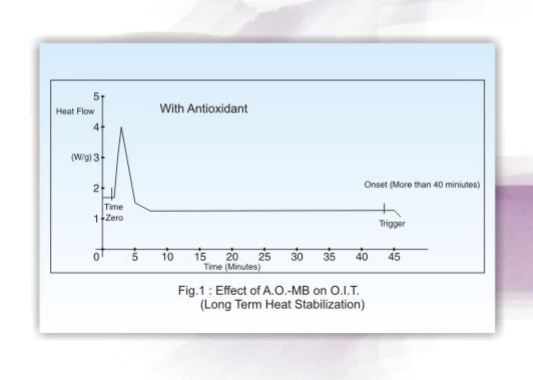

* Maintain original melt flow (Refer fig. No.1)

- Improvement in long term thermal stability/heat protection of polymers.

- Does not impart any color.

- Increases Oxidative

- Induction Time( OIT) (Refer fig. No.2)

* High quality dispersion

Applications & Uses

- Markets

- Applications

- Compatible Polymers & Resins

- Plastics & Elastomers Processing Methods

- Recommended Usage

0.5-1%. or as per requirement

- Applications

- Blow Molding/ Roto Molding

- Cables

- Pipes and Profiles

- Specialty films and molded parts

- Sheet extrusion and filament yarn

Properties

- Physical Form

- Appearance

- Translucent Granules

Packaging & Availability

- Packaging

Material is packed in HDPE woven sacks of 25 Kgs.