Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- CASE Ingredients Functions

Features & Benefits

- Labeling Claims

- CASE Ingredients Features

- Features and Benefits

- APEO Free

- Provides the ability to compound at high filler loading

- Features and Benefits

- APEO Free

- High filler acceptance

- Tough

Applications & Uses

- Markets

- Applications

- Industrial Additives End Use

- Applications and Markets

Typical Applications

- Asphalt Compatible

- Metal Coating

- Automotive Underbody

- Mulch Coatings

Markets

- Textiles

- Nonwovens

- Paints and Coatings

- Applications

- Underbody Coatings

- Metal and landscaping coatings

- A Range of Adhesive Applications

Mallard Creek Polymers offers products to suit most surfaces, from metals like copper and stainless steel to glass and ceramics and even very low-energy surfaces like polyethylene. These products consist of many acrylic and styrene-acrylic emulsion polymers, and styrene-butadiene latexes that have a balance of properties to fit adhesive application requirements. Formulations can be created with Rovene® products by including tackifiers, fillers, pigments and additives as appropriate.

We can provide polymers for any of these applications:

- Removable Adhesives

- Laminating Adhesives

- Contact Adhesives

- Pressure Sensitive Adhesive

- Release Coatings

- Sealants

- Packaging Adhesives

- Construction Adhesives

- Tape Saturation

- Substrates

- Wood

- EPDM

- Metal

Properties

- Physical Properties

| Value | Units | Test Method / Conditions | |

| Glass Transition Temperature | 12 | °C | — |

| Glass Transition Temperature | 11 | °C | — |

| Solids Content | 55 | % | — |

| pH | 7.3 | — | — |

| pH | 7.2 | — | — |

| Minimum Film Forming Temperature | 17 | °C | — |

| Viscosity | max. 1500 | cPs | — |

Technical Details & Test Data

- A Commitment to Collaboration

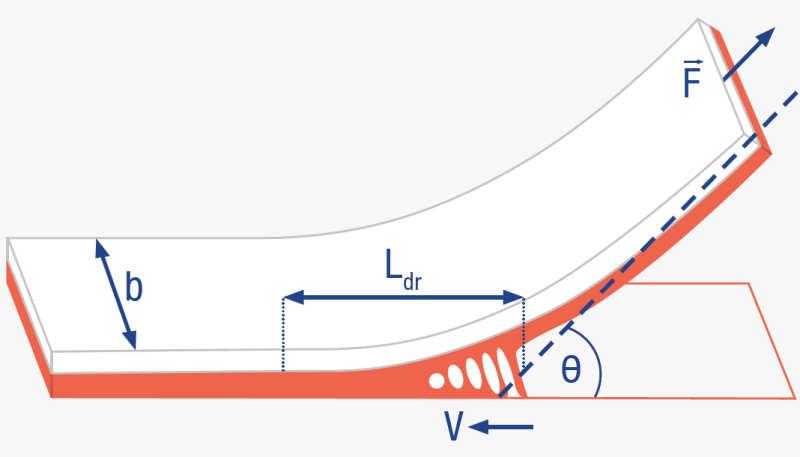

Developing an adhesive for your application involves a comprehensive look at your end-use application, the materials and substrates involved, the environment in which the adhesive will be used and the stresses it will experience. When evaluating stress, the most important performance properties to consider are peel adhesion, tack, and shear.

Mallard Creek Polymers will consult with your team to deliver the precise performance properties you require for your unique challenges and applications. Our experts can provide accurate performance test data for adhesive materials and can help your engineers select the most appropriate chemistry.

- Pressure Sensitive Adhesives

Performance Testing

We leverage a wide range of polymer characterization tools to help identify the right polymer for specific applications. We use thermal glass transition, dynamic mechanical analysis, gel content, water resistance, and tensile and elongation evaluations. We also perform tack, peel and shear tests for pressure-sensitive adhesive grades, according to Pressure Sensitive Tape Council standards, as well as specific tests for spray adhesive, lamination and flooring applications.

Pressure Sensitive Adhesives

PSAs can be either removable or permanent and should be optimized for the surface to which they will be applied. Surface energy is a particular concern, together with the usual tack, peel and sheer properties needed by the application.