Knowde Enhanced TDS

Identification & Functionality

- Chemical Name

- Product Type

- CASE Ingredients Functions

- Technologies

Features & Benefits

- CASE Ingredients Features

- Ready-to-Use Product Features

- Key Attributes

• Plastic safe—compatible with most sensitive substrate used in electronic parts and enclosures

• Moderately fast evaporation rate

ATTENTION! FOR INDUSTRIAL OR LABORATORY USE ONLY. NOT FOR RETAIL SALE IN CALIFORNIA, UTAH, AND NEW HAMPSHIRE.

Applications & Uses

- Applications

- Application Area

- Compatible Polymers & Resins

- Compatibility with Substrate

The 4351 Thinner 1 is a mild solvent system compatible with most materials found on printed circuit assemblies and with chemically sensitive plastics like ABS and PVC.

WARNING: Some degree of surface etching is often desirable to ensure good adhesion to some substrates. If adhesion failures are observed, the more aggressive 435 Thinner may provide better adhesion characteristics. As an electronic cleaner or shielding enclosure cleaner, it helps remove moisture, wax, greases, oils, and other contaminants that can cause coating defects.

- Applications

- EMI / RFI Shielding

- Galvanic corrosion resistance

- ESD Protection

- Grounding

- Electroplating plastics

Industries

- Aerospace

- Communications

- Consumer Electronics

- Defense

- Electric Vehicles

- Instrumentation

- Medical equipment

- Research

- Applications & Usages

- This thinner is used to dilute EMI/RFI shielding coatings that require mild, plastic safe solvents. As a cleaner, it is effective at removing various contaminants like oil and greasy flux residues without harming the substrate prior coating the surface.

- Binder Systems

Acrylic is the most used binder for plastic enclosures. It cures at room temperature, applies easily, and creates a durable coating.

Water based urethane is the only choice for architectural applications because of its low VOC content. It is non-flammable, has no noxious vapors, and is not a dangerous good when shipped by air.

Solvent based urethane creates a flexible coating and applies very thin. It adheres strongly to most substrates including plastics, metals, and glass.

Epoxy is used when extreme durability and strong chemical resistance is needed. It offers mar and scratch resistance, very strong adhesion, extreme abrasion and impact resistance. Epoxy-based paints are the best choice for coating metals and concrete.

- Conductive Fillers

Carbon is best for low frequency shielding, musical instruments, and grounding.

Nickel is suitable for most device-level shielding applications. It provides modest shielding, durability, and excellent corrosion resistance.

Silver offers the best shielding and corrosion resistance. It is also the best choice for boardlevel and package level shielding. It can be applied very thin.

- Conductive Paints Technical Details

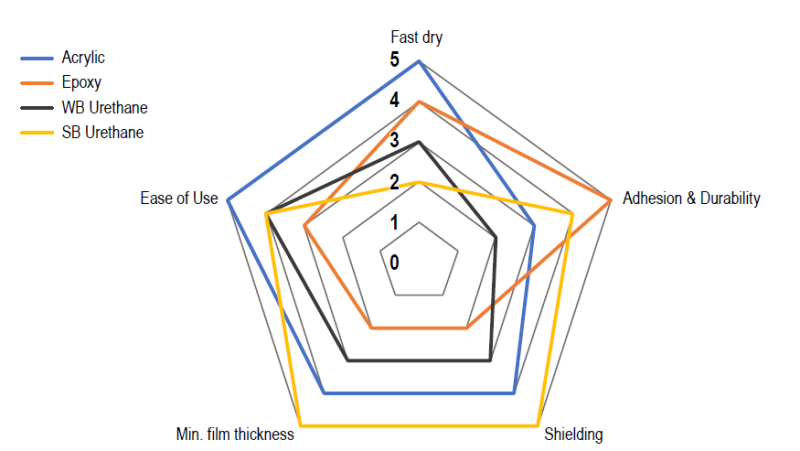

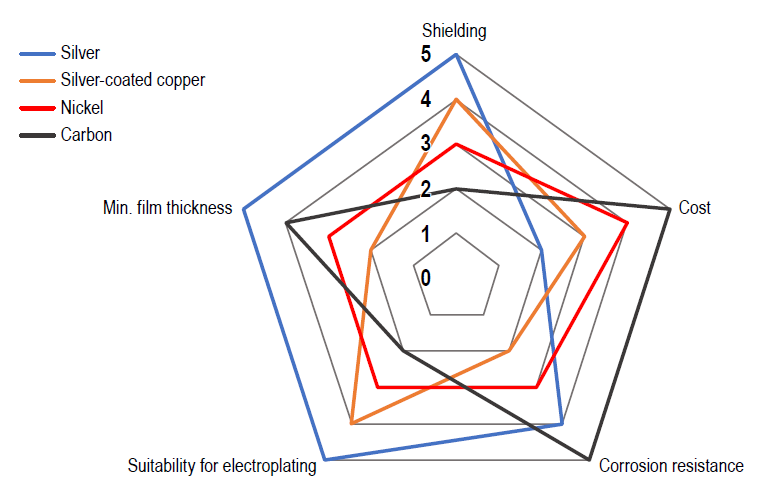

The general properties of conductive paints vary by their binder system and conductive fillers. Therefore, it is important to choose the right combination your specific application. The below graphs qualitatively compare the performance of conductive paints based on their binder and conductive filler systems.

Graph 1. Performance comparison of conductive paints based on the binder type. 5 represents the highest performance and 1 represents the lowest performance.

Graph 2. Performance comparison of conductive paints based the filler type. 5 represents the highest performance and 1 represents the lowest performance.

Graph 2. Performance comparison of conductive paints based the filler type. 5 represents the highest performance and 1 represents the lowest performance.- Spray Gun Thinning Instructions

- Make necessary adjustments according to your spray gun equipment usage instructions. Dilutions of 1.0 (paint):1.0 (thinner) is a good starting point. If sagging is observed, reduce the thinner ratio.

Properties

- Physical Form

- Appearance

- Clear

- Odor

- Rubbing alcohol

- Physical Properties

- Environmental Properties

- Typical Properties

- Uncured Properties

- EMI/RFI Shielding Paints

Carbon Nickel Silver Silver-coated Copper ESD COATINGS Solvent based Acrylic 838AR 841AR 842AR 843AR 844AR Water based Urethane — 841WB 842WB 843WB 844WB Solvent based Urethane — — 842UR — — Solvent based Epoxy — 841ER 842ER 843ER —

| Value | Units | Test Method / Conditions | |

| Density (at 25 °C, 77 °F) | 0.8 | g/mL | — |

| Viscosity (at 25 °C, 77 °F) | approx. 1 (0.01) | cP (Pa·s) | Brookfield SP1 |

| Value | Units | Test Method / Conditions | |

| Volatile Organic Compound (VOC, 100%) | 800 | g/mL | — |

| Value | Units | Test Method / Conditions | |

| Flash Point | 15 (59) | °C(°F) | Closed Cup |

| Vapor Pressure (at 25 °C, 77 °F) | 7.5 (56) | kPa (mm of Hg) | — |

| Value | Units | Test Method / Conditions | |

| Boiling Point | 65 (149) | °C(°F) | — |

Safety & Health

- ESD Safe Coating

- ESD Safe Coating - These are durable coatings that eliminate electrostatic discharge on a wide variety of substrates.

Packaging & Availability

- Packaging Type

- Packaging Information

Cat. No. Packaging Net Volume Net Weight Packaging Weight 4351-1L Can 945 mL

31.9 fl oz

756 g

1.66 lb

4.7 kg

10 lb (Case pack of 5)

4351-4L Can 3.78 L

1 gal

3.0 kg

6.66 lb

3.62 kg

7.98 lb