Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- Ready-to-Use Product Features

- Key Attributes

- Low exotherm

- Convenient 1A:1B volume mix ratio

- High compressive and tensile strength

- Excellent adhesion to a wide variety of substrates including metals, composites, glass, ceramics, and many plastics

- Excellent electrical insulating characteristics

- Extreme resistance to water and humidity

- Solvent-free

- Recommended Preparation

- Clean the substrate with Isopropyl Alcohol, MG #824, so the surface is free of oils, dust, and other residues.

Applications & Uses

- Markets

- Applications

- Compatible Substrates & Surfaces

Properties

- Typical Properties

- Cured Properties

- Uncured Properties

- Cure Instructions

Allow to cure at room temperature for 24 hours, or cure in an oven at one of these time/temperature options:

Temperature 65 °C 80 °C 100 °C Time 2 h 1 h 45 min

| Value | Units | Test Method / Conditions | |

| Mix Ratio | 1:1 | Volume | — |

| Mix Ratio | 1.1:1 | Weight | — |

| Working Time | 2 | h | — |

| Value | Units | Test Method / Conditions | |

| Breakdown Voltage | 48300 | V | — |

| Compressive Strength | 87 | N/mm2 | — |

| CTE (After Tg) | 114 | ppm/˚C | — |

| CTE (Prior Tg) | 142 | ppm/˚C | — |

| Dielectric Strength | 386 | V/mil | — |

| Glass Transition Temperature (Tg) | 50 | °C | — |

| Hardness D | 81 | — | — |

| Intermittent Temperature | 200 | ˚C | — |

| Lap Shear (Aluminum) | 16 | N/mm2 | — |

| Lap Shear (Stainless Steel) | 13 | N/mm2 | — |

| Resistivity | 8.2 x 10¹² | Ω·cm | — |

| Service Temperature Range | -30 to 175 | ˚C | — |

| Tensile Strength | 23 | N/mm2 | — |

| Thermal Conductivity (at 25˚C) | 0.7 | W/(m·K) | — |

| Value | Units | Test Method / Conditions | |

| Mixed Density | 1.67 | g/mL | — |

| Viscosity (at 25 ˚C) ⁽ᵃ⁾ | 33 | Pa·s | — |

| Viscosity (at 25 ˚C) ⁽ᵇ⁾ | 12 | Pa·s | — |

Regulatory & Compliance

Technical Details & Test Data

- Mixing

- Scrape settled material free from the bottom and sides of the part A container; stir the contents until homogenous. Use a paint shaker if available.

- Measure 2 parts by volume of the part A and pour into the mixing container. Ensure all contents are transferred by scraping the container.

- Measure 1 part by volume of the part B and pour into the mixing container. Ensure all contents are transferred by scraping the container.

- Thoroughly and gently mix parts A and B together. Avoid introducing air bubbles.

- To de-air, let sit for 15 minutes or put in a vacuum chamber at 25 inHg for 2 minutes.

- If bubbles are present at the top, break them gently with the mixing paddle.

- Pour the mixture into a container holding the components to be protected.

- Close the part A and B containers tightly between uses to prevent skinning.

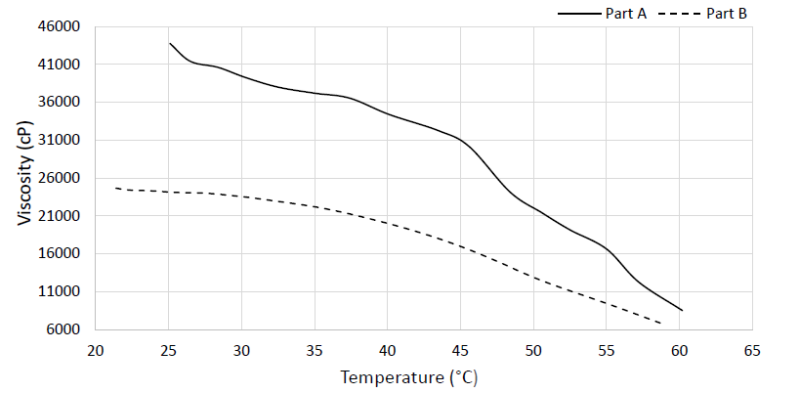

- Viscosity vs. Temperature

Packaging & Availability

- Available Packaging

Cat. No. Packaging Net Vol. Net Wt. 832TC-450ML 2 Bottle kit 450 mL 751 g 832TC-2L 2 Can kit 1.7 L 2.83 kg 832TC-8L 2 Can kit 7.2 L 12.0 kg 832TC-40L 2 Pail kit 40 L 66.8 kg

Storage & Handling

- Shelf Life

- 5 Years

- Storage and Handling

- Store between 16 and 27 ˚C in a dry area, away from sunlight (see SDS). Storage below 16 °C can result in crystallization.