Knowde Enhanced TDS

Identification & Functionality

- Polymer Name

- CASE Ingredients Functions

- Composite Materials Functions

- Plastics & Elastomers Functions

- Technologies

- Product Families

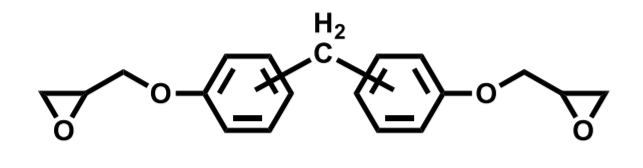

- Molecular Structure

Features & Benefits

- Labeling Claims

- CASE Ingredients Features

- Materials Features

- Features

- Highly adhesive to metal, porcelain, concrete

- Excellent insulation property

- High heat resistance

- High chemical resistance

- High water resistance

Applications & Uses

- Markets

- Applications

- Adhesive & Sealant Type

- Plastics & Elastomers End Uses

- Applications & Use

jER™ 1750 is used for Electrical and electronic applications (Sealant, casting agent, adhesives, and so on) and fiber reinforced plastics.

Properties

- Color

- Physical Form

- Appearance

- Pale yellow transparency

- Physical Properties

- Typical Properties

- Note

* Based on Mitsubishi Chemical test methods.

| Value | Units | Test Method / Conditions | |

| Density (at 25°C) | 1.187 | g/cm³ | Density Meter (Vibration type)* |

| Viscosity (at 25°C) | 10 - 15 | P | Capillary Viscometer* |

| Value | Units | Test Method / Conditions | |

| Epoxy Equivalent Weight (WPE) | 156 - 163 | g/eq | Potentiometric Titration* |

| Total Chloride Content | 800 | ppm | — |

Technical Details & Test Data

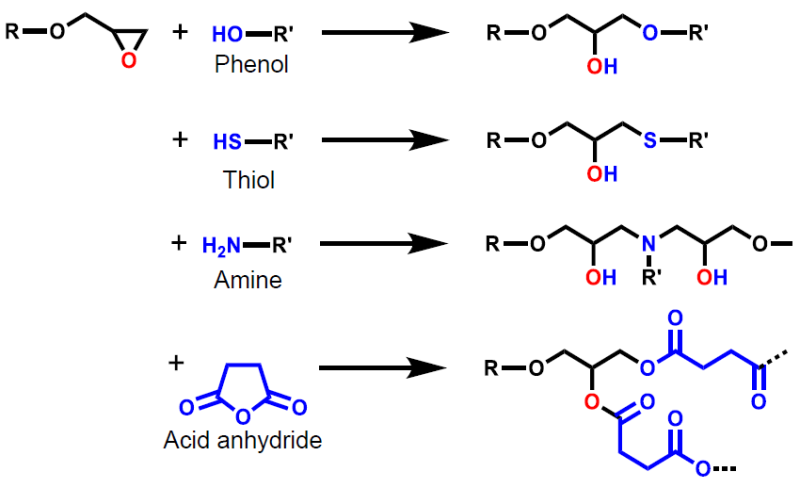

- Typical Reactions with Representative Hardeners

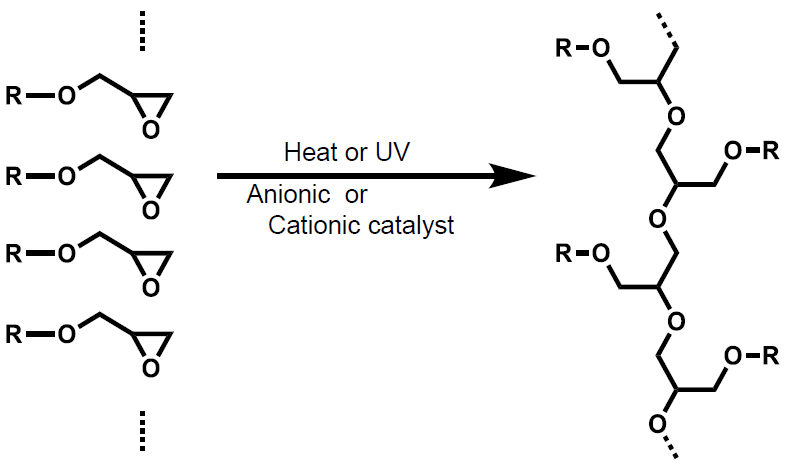

- Typical Reactions with Self Polymerization

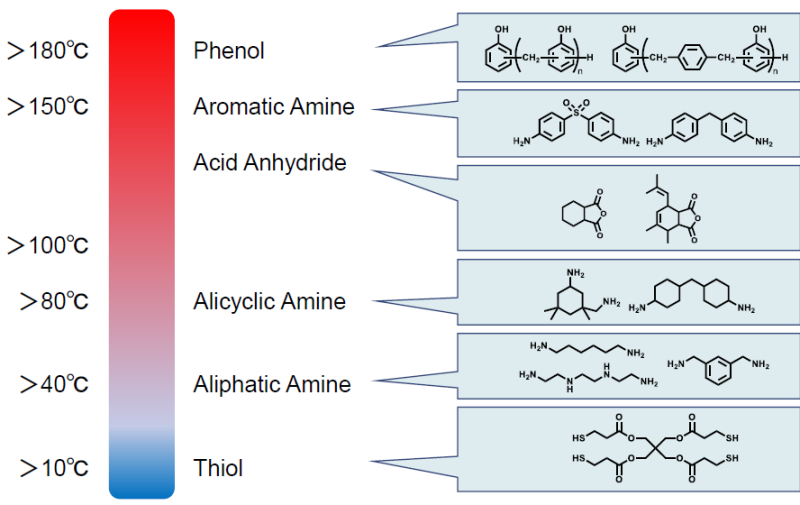

- Selection of Hardeners

Appropriate choice of Hardener for a desired curing temperature

- General Ways to Use Epoxy

- Epoxy resin forms 3D crosslinked network structure

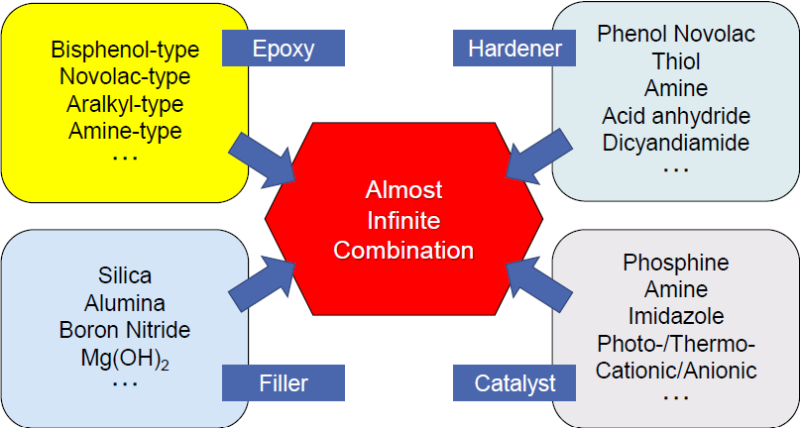

- Abundant choices of Epoxy/Hardener combination

Packaging & Availability

- Packaging Information

- Steel drum with 200 kg net and metal can with 20 kg net

Storage & Handling

- Shelf Life

- 3 months

- Storage and Handling

Carefully read the SDS before using, handling, transporting, storing or disposing. jER™ 1750 should be stored in tightly closed containers under exclusion of humidity at gentle temperatures. Avoid exposure to direct sunlight. Under these storage conditions the product has a minimum shelf life of three months from date of delivery.