Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Polymer Name

- CASE Ingredients Functions

- Composite Materials Functions

- Plastics & Elastomers Functions

- Technologies

- Product Families

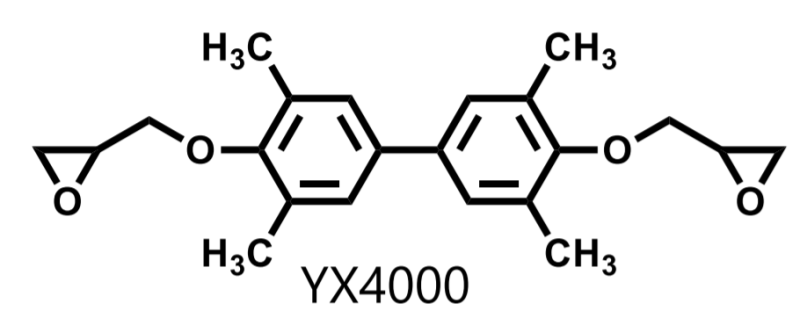

- Molecular Structure

Features & Benefits

- CASE Ingredients Features

- Materials Features

- Features

- Highly adhesive to metal, porcelain, concrete

- Excellent insulation property

- High heat resistance

- High chemical resistance

- High water resistance

- Product Highlights

- Solid type (Flake)

- Significantly low melt viscosity (Melting point: 108°C)

- Good balance between adhesiveness and rigidity against stress.

- Low chroline content

- Low water absorption

Applications & Uses

- Markets

- Applications

- Compatible Substrates & Surfaces

- Coating Type

- Plastics & Elastomers End Uses

- Usage & Application

jER™ YX4000 is a solid-type epoxy resin with well-balanced properties and is used for :

- Electrical and electronic applications(EMC, solder resist, PCB, etc.)

- Composites, Potting & encapsulation materials.

- Powder coating

- Adhesives

- Composites

Properties

- Color

- Physical Form

- Appearance

- Yellow solids

- Physical Properties

- Typical Properties

- Properties Formulation

Value Unit Method jER™ YX4000 100 phr Phenol Novolac 56 phr Triphenylphosphine 1 phr Curing condition 120°C/2h + 175°C/6h

Cured State Properties Tg 147 °C Dynamic Mechanical Analysis

Elastic modulus@40°C 1.6 GPa Dynamic Mechanical Analysis

Elastic modulus@250°C 18 MPa Dynamic Mechanical Analysis

Coefficient of thermal elongation(α1) 70 ppm Thermo Mechanical Analysis

Coefficient of thermal elongation(α2) 191 ppm Thermo Mechanical Analysis

Td5 372 °C Thermogravimetry-Differential, Thermal Analysis (Heating rate: 10°C/min, in air)

| Value | Units | Test Method / Conditions | |

| Density (at 25°C) | 1.15 | g/cm3 | Pycnometer |

| Harsh Hydrolyzable Chloride | 400 | ppm | Potentiometric Titration |

| Melting Point | 108 | °C | Differential Scanning Calorimetry |

| Value | Units | Test Method / Conditions | |

| Epoxy Equivalent Weight (WPE) | 180 - 192 | g/eq | Potentiometric Titration |

| Total Chloride Content | 1000 | ppm | — |

Technical Details & Test Data

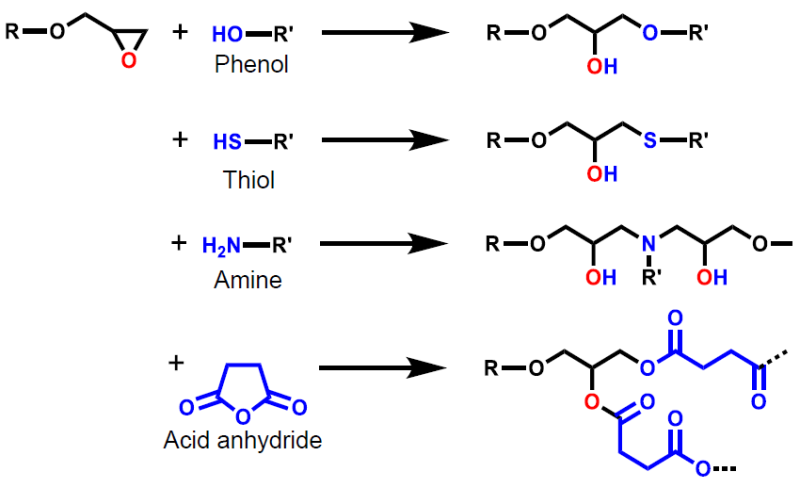

- Typical Reactions with Representative Hardeners

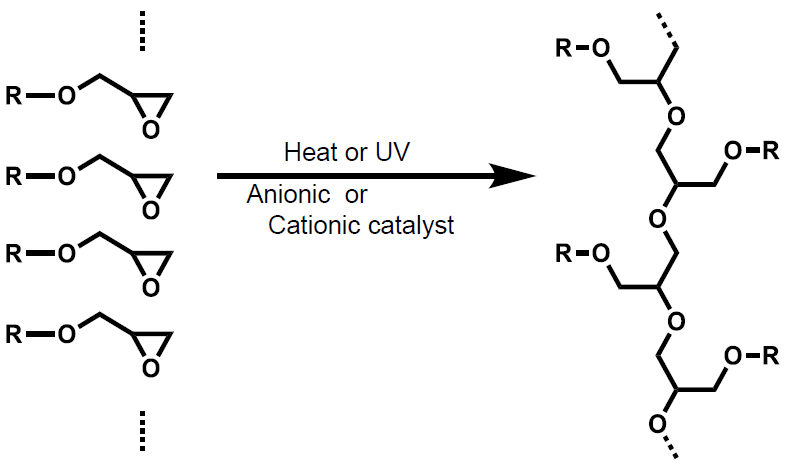

- Typical Reactions with Self Polymerization

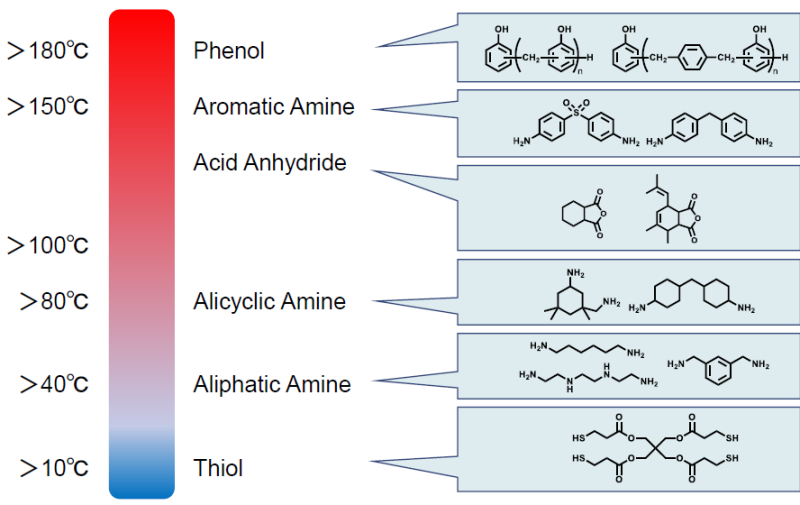

- Selection of Hardeners

Appropriate choice of Hardener for a desired curing temperature

- General Ways to Use Epoxy

- Epoxy resin forms 3D crosslinked network structure

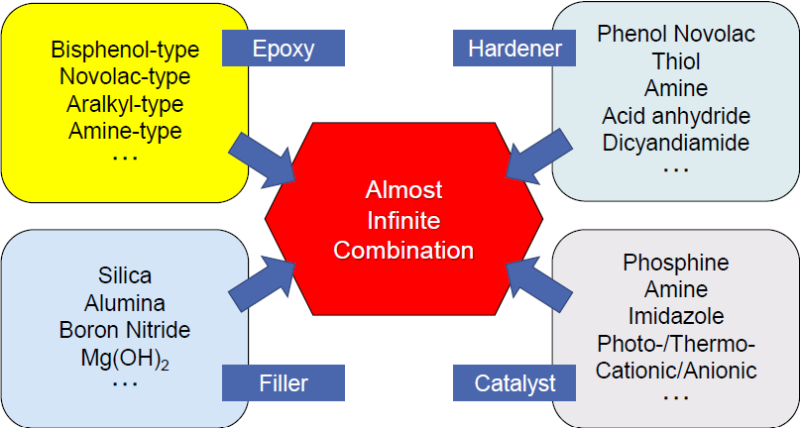

- Abundant choices of Epoxy/Hardener combination

Packaging & Availability

- Packaging Type

- Packaging Information

- Paper bag with 20 kg net

Storage & Handling

- Shelf Life

- 3 months

- Storage and Handling

Carefully read the SDS before using, handling, transporting, storing or disposing. jER™ YX4000 should be stored in tightly closed containers under exclusion of humidity at gentle temperatures. Avoid exposure to direct sunlight. Under these storage conditions the product has a minimum shelf life of three months from date of delivery.