Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Polymer Name

- Plastics & Elastomers Functions

- Technologies

Features & Benefits

- Materials Features

- Product Benefits

- High temperature

- Chemical resistance

- Hydrolysis resistance

- Excellent fatigue resistance

- Low moisture absorption

Applications & Uses

- Markets

- Applications

- Plastics & Elastomers End Uses

- Plastics & Elastomers Processing Methods

- Industrial/Application Examples

- Automotive - Bushings, washers, pistons, brackets, handles

- Aerospace - Latches, rings, hinges, spacers, seals, adapters

- Electrical - Pins, fasteners, end effectors, connectors, panels

- Medical - Clamps, vanes, housings, bushings, gears, valves

- Energy - Seals, bearings, plugs, umbilicals, back-up rings

- Industrial - Valve plates, column packing, gears, valve seats

Properties

- Flame Rating

- Mechanical Properties

- Chemical Properties

- Thermal Properties

- Electrical Properties

| Value | Units | Test Method / Conditions | |

| Specific Density | 1.41 | g/cm³ | ASTM D792 |

| Tensile Strength | 336 | MPa | ASTM D638 |

| Tensile Modulus of Elasticity | 37 | Gpa | ASTM D638 |

| Tensile Elongation | 1.8 | % | ASTM D638 |

| Flexural Strength | 448 | MPa | ASTM D790 |

| Flexural Modulus of Elasticity | 31 | GPa | ASTM D790 |

| Shear Strength | 126 | MPa | ASTM D732 |

| Compressive Strength | 338 | MPa | ASTM D695 |

| Compressive Modulus of Elasticity | 8 | Gpa | ASTM D695 |

| Hardness | 93 | Shore D | ASTM D2240 |

| Notched Izod Impact | 106 | J/m | ASTM D256 |

| Unnotched Izod Impact | 954 | J/m | ASTM D4812 |

| Value | Units | Test Method / Conditions | |

| Moisture Content (24 hours) | 0.45 | % by wt | ASTM D570 |

| Value | Units | Test Method / Conditions | |

| Glass Transition Temperature | 153 | °C | ASTM D3418 |

| Melting Point | 345 | °C | ASTM D3418 |

| Deflection Temperature (1.8 MPa) | 337 | ºC | ASTM D648 |

| Value | Units | Test Method / Conditions | |

| Surface Resistivity | max. 10⁵ | ohm/sq | ASTM D257 |

| Flammability | V-0 | — | UL 94 (1) |

Regulatory & Compliance

- Certifications & Compliance

Technical Details & Test Data

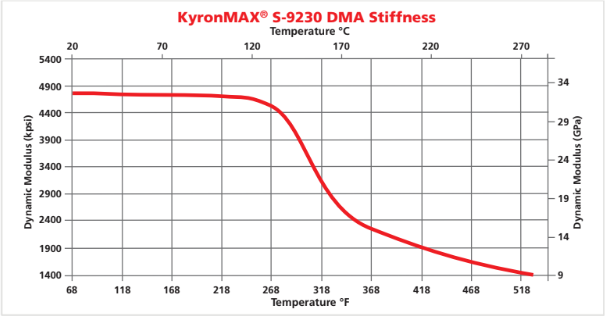

- KyronMAX® S-9230 DMA Stiffness

KyronMAX® materials are lightweight and, when molded, parts are 75% lighter than steel and almost 40% lighter than aluminum. By utilizing the lower density of KyronMAX®, customers can simultaneously realize lower costs and lighter parts, while also taking advantage of unmatched tensile and toughness properties.

The better “practical toughness” values are achieved with lower filler loading, which increases the material’s elongation at yield. KyronMAX® molded parts are more likely to yield, rather than fracture under high-stress loads. KyronMAX® stronger fibers and lower filler loadings further elevate molded product performance with significantly better knit line strength compared to other filled polymers.

Aluminum bracket with half FEA analysis (left) and KyronMAX® final molded part (right). The FEA analysis is used to translate a metal part into a lightweight plastic molded part, while matching or exceeding the strength and stiffness of the original metal part.

Mitsubishi Chemical Advanced Materials (MCAM) can take your metal parts and use our proprietary Finite-Element Analysis (FEA) to engineer a high-performance product with KyronMAXⓇ materials. MCAM's unique FEA data offers a solution to accurately predict the mechanical performance of a part in real world applications with key features including mechanical stress, plastic injection molding flow, fatigue, and motion.

- Note

- (1) Does not represent actual testing conducted by MCAM but is an estimated rating based on available data. The UL 94 Test is a laboratory test and does not relate to actual fire hazard.