Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Polymer Name

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- Materials Features

- Product Features

- High temperature

- Esd additives for static dissipation

- Good dimensional stability

- Excellent chemical

- Corrosion resistance

Applications & Uses

- Markets

- Applications

- Plastics & Elastomers End Uses

Properties

- Color

- Flame Rating

- Typical Properties

| Value | Units | Test Method / Conditions | |

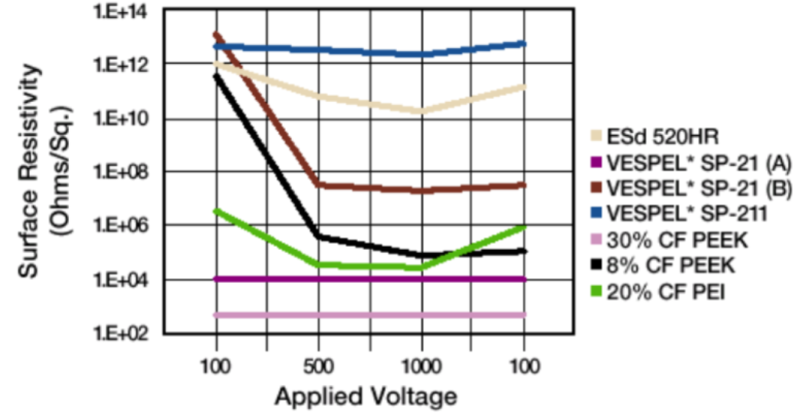

| Surface Resistivity | 10¹⁰ - 10¹² | ohms/sq | — |

Regulatory & Compliance

- Certifications & Compliance

- Chemical Inventories

Technical Details & Test Data

- Engineering Notes

It is important to know how applied voltage affects the resistance of a material. Some materials exhibit high resistance at low voltages, but when subjected to harsher conditions, they can fall. This is due to dielectric breakdown and is irreversible. This chart illustrates the effect of sequential applications of 100 through 1,000 volts, then a return to 100 volts to determine the hysteresis. Since static electricity can be several thousand volts, consistent performance across the voltage range must be considered.

Some materials are very inconsistent and vary on the "grain" of machining. One pair of lines illustrate the typical variation from side to side (A to B) of the same sample. This example demonstrates the need for consistent behavior in service.