Knowde Enhanced TDS

Identification & Functionality

- Product Type

- Technologies

- Product Families

Features & Benefits

- Ready-to-Use Product Features

Applications & Uses

- Applications

- Application Method

- Compatible Substrates & Surfaces

- Coating Application

It is recommended that coating application be performed in a clean environment to minimize surface defects. To make the coating solution, in a dust-free container combine Part A and Part B using the following ratio: 3:1 (A:B) in weigth. Mix well by stirring briefly (avoid vigorous stirring to minimize foam formation). The coating may be applied immediately after mixing by dipping, flowing, spinning, rolling or spraying.

For spray application of the coating, an HVLP spray gun with a nozzle size of < 1.0 mm is recommended, and the pressure should be set to approximately 25 to 30 psi.

For best coating performance, use the coating solution within 24 hours after mixing, or store the mixed solution in a freezer for later use. If stored in freezer, warm the solution up to room temperature before application.- Clean Up

Clean tools and flush equipment thoroughly with acetone before product dries. Once coating is dry, the tools will not clean with acetone or any other solvent.

- Applications

NANOMYTE SuperCN is applicable to industrial condensers in general, and more particularly surface condensers in power plants. The durable hydrophobic coating can also be used to impart anti-fouling and easy-to-clean properties to the metallic surfaces of a variety of commonly used consumer products, such as kitchen appliances, shower heads, and hand rails, to name a few.

Properties

- Physical Form

- Physical Properties

- Technical Data

- Abrasion Resistance

* Taber abrasion test, polycarbonate substrate, CS - 10F wheels, 500g load, 500 cycles

- UV Resistance

- No visual damage after 200 hours of dry QUV test (at 1.5 W/m², 340 nm, 55ºC)

| Value | Units | Test Method / Conditions | |

| Viscosity (at 20°C, Mixed) | 5 - 15 | cP | — |

| Abrasion Resistance (Δ Haze)* | max. 2 | % | ASTM D1044 Taber Abrasion Test |

| Value | Units | Test Method / Conditions | |

| Contact Angle on Fully Cured Film (Hexadecane) | 60 - 70 | degree | — |

| Contact Angle on Fully Cured Film (Water) | 105 - 115 | degree | — |

| Coverage (Theoretical at 3μm DFT) | 400 - 600 | ft²/L | — |

| Cured Film Thickness | 1 - 10 | μm | — |

| Curing Temperature | min. 85 | °C | — |

| Mix Ratio (A:B, by weight) | 3 : 1 | — | — |

Technical Details & Test Data

- Surface Preparation

Ensure surfaces to be coated are clean and dry – the surfaces should be water-break free before coating application. The coating can be applied with or without the use of a primer depending on the substrate. NEI supplies a primer product, NANOMYTE® SR-Primer, which works well with a range of plastics. The primer may be applied by dipping, flowing, spinning, rolling or spraying.

For spray application of the primer, an HVLP spray gun with a nozzle size of < 1.0 mm is recommended, and the pressure should be set at approximately 25 to 30 psi. The primed parts should then be dried at 70ºC for 10 min before application of NANOMYTE® SuperCN.- Curing

NANOMYTE® SuperCN is thermally cured at an elevated temperature. Recommended curing conditions:

- PMMA: 4 hours at 85°C

- Polycarbonate: 1 hour at 120°C

- Other: 30 minutes at 150°C (for substrates that can withstand high temperatures)

Shorter cure times / reduced temperatures may also be used depending on surface properties and performance requirements; test samples for desired performance when deviating from recommendations.

- Technology Description

NANOMYTE® SuperCNTM is a new class of durable hydrophobic coating designed specifically for metal surfaces. The patent pending coating has a unique combination of properties that includes hydrophobicity and oleophobicity, specifically good adhesion to stainless steel, superior abrasion and erosion resistance. While the coating was originally developed for promoting dropwise condensation on stainless steel condenser tubes to enhance heat transfer efficiency, it can also be used to impart anti-fouling and easyto- clean properties to other metallic surfaces such as brass and titanium.

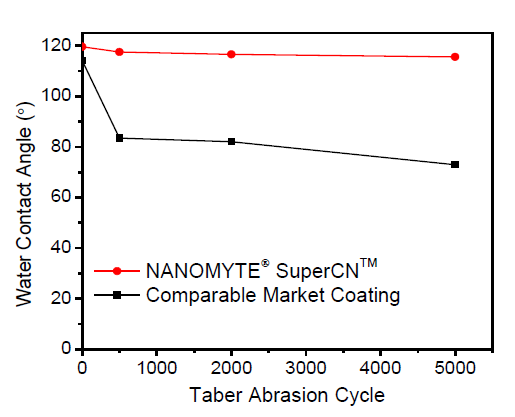

The figure below shows the water contact angles as a function of abrasion cycles from a Taber abrasion test for NANOMYTE® SuperCNTM as compared with a comparable market coating on a stainless steel substrate. Note that the SuperCN coating maintained high water contact angles after 5000 cycles of Taber abrasion test, whereas a comparable coating in the market lost its hydrophobicity after only 500 cycles.

Water Contact Angle as a function of Abrasion Cycle with a Taber Test (Testing Conditions: 316 stainless steel substrate, Model 5135 Taber Abraser, CS-5 Felt wheel, 500 gram load).- Dropwise Condensation

Industrial heat exchanger designs are based on filmwise condensation, a process in which steam condenses to form a layer of water on heat exchanger tubes. The water film acts as a barrier for heat transfer because of its lower thermal conductivity (0.613 W/m-K) relative to the walls of the heat exchanger tubes (~400 W/m-K for copper).

The occurrence of dropwise condensation, a process in which steam condenses to form droplets atop condensing surfaces, can improve the heat transfer coefficient by over an order of magnitude. The formation of small water droplets that quickly roll off heat exchanger tubes, as opposed to films, lowers the thermal resistance caused by the moisture. Imparting superhydrophobicity to condensing surfaces promotes dropwise condensation.

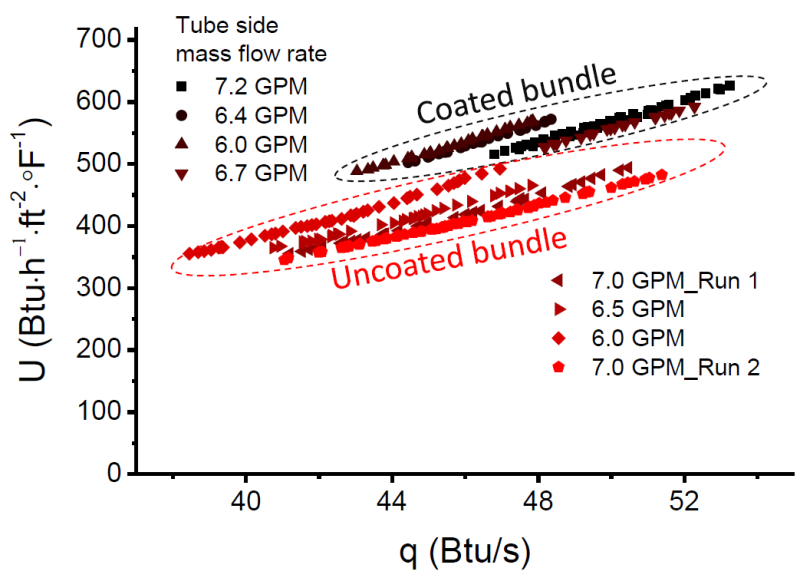

The graph below shows the result of heat transfer coefficient testing under simulated end-use conditions with a prototype U-tube bundle coated with NANOMYTE® SuperCNTM. A consistent ~30% increase in the overall heat transfer coefficient (U) over a range of heat transfer rates and cooling water flow rates was observed while confirming dropwise condensation under dynamic steam loading. Post-test measurements revealed no measurable coating degradation through the entire main section of the heat exchanger.

Storage & Handling

- Storage and Handling

Precautions for Safe Handling

Appropriate personal protective equipment should be used at all times. Avoid contact with eyes, skin and clothing. Provide good ventilation or extraction and avoid prolonged or repeated breathing of vapor. Keep away from heat, sparks, flames and other sources of ignition. Wash hands thoroughly after handling.

Conditions for Safe Storage

For best coating performance, store Part B in a freezer or a refrigerator. Keep the containers of Part A tightly sealed and store in a cool and dry place. Avoid storage above 30 °C / 86 °F and contamination with incompatible materials. Keep away from heat, sparks, flames and other sources of ignition. Residual vapors might explode on ignition.