Knowde Enhanced TDS

Identification & Functionality

- CASE Ingredients Functions

- Technologies

- Product Families

Features & Benefits

- CASE Ingredients Features

Applications & Uses

- Markets

- Applications

- Ink & Toner Type

Properties

- Physical Form

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Adhesives | Al / Cu | — | — |

| Breakdown Voltage (Thickness 29μm on Al) | 3.2 | KV | 10sec / Electrode distance 20mm |

| Coating Method | Screen Printing | — | — |

| Insulation Resistance (Thickness 29μm on Al) | 4.2×10^9 | Ω | 500V / 10sec / Electrode distance 20mm |

| Reflection (at 460nm, Thickness 30μm or more) | min. 93 | % | Reflectance is relative comparison with Spectralon® (Porous PTFE) |

| Viscosity (at 10 rpm) | 60 - 120 | Pa.s | Viscosity can be adjusted by the customer coating conditions. |

Technical Details & Test Data

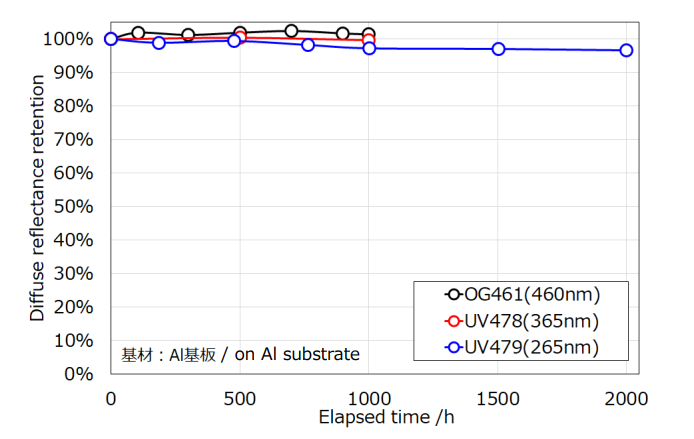

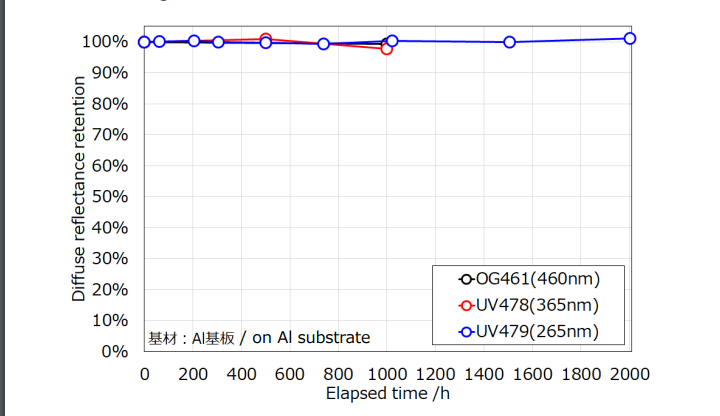

- High Temperature Resistance

Holding Temperature : 200°C

- Weatherability

Holding Condition : 60°C 90%RH

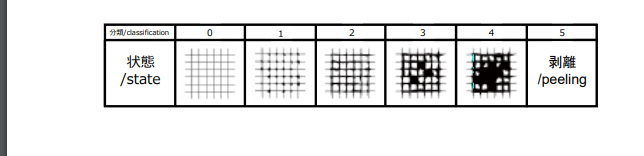

- Adhesive

- Cross Cut Test before and after Thermal shock test

- Thermal shock test condition : 260°C→25°C water × 10times

OG461

before/afterAl 1/1 Cu 1/1 SUS

- Recommended Blending Conditions

Blending Condition

Blend Ratio

- Main Body : OG461 = 100 wt%

- Curing Agent OG830 for OG461 = 1.0 wt%

- Pick Main Body up from the refrigerator

- And Keep it in the room and store until main body up to room temperature (>6 Hours) as unopened (Avoid Dew condensation)

- Curing Agent solution should NOT be in the refrigerator.

Thinner

- In case it need to adjust viscosity

Storage Condition

- Main Body : OG461 = Refrigerated storage below 5°C

Shelf life : 3 Months after manufacturing - Curing Agent : OG830, OG831, OG840 = Room Temperature

Shelf life : 6 Months after manufacturing

- Recommended Curing Conditions

Drying Condition

- 90°C for 10 min in the Box Oven or Equivalent Heat amount of Belt dryer

- Good air Ventilation is needed

Curing Condition

- OG461 : 180°C for 120 min(minimum) in the Box Oven or Equivalent Heat amount of Belt dryer UV479

- 180°C for 120~180 min(minimum) in the Box Oven or Equivalent Heat amount of Belt dryer

- Feel dry surface by the finger touch is good enough in the above condition